Near-field ultrasonic cavitation and fluid shearing combined type micro-gear finishing machining device and machining method

A fluid shearing and finishing technology, applied in the field of precision and ultra-precision machining, can solve the problems of difficulty in ensuring machining quality, weak far-field ultrasonic cavitation, and limited improvement of solid particle impact strengthening, and achieves improved grinding and Ability to polish, overcome cavitation effects, low utilization, green and flexible finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

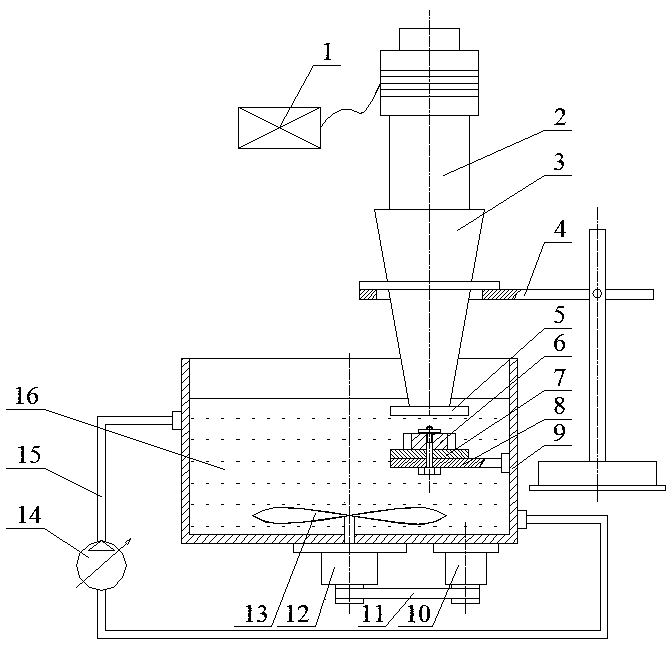

[0033] Attached below figure 1 , describe the present invention in detail.

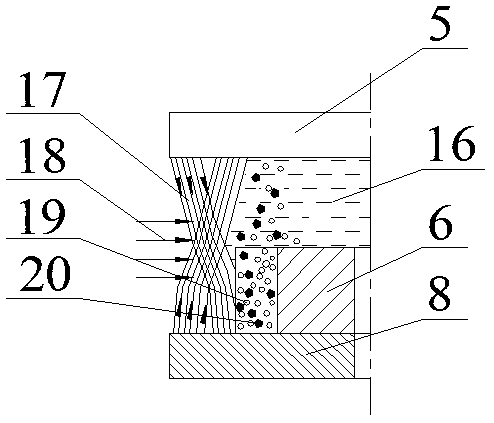

[0034] A near-field ultrasonic cavitation composite fluid shear micro-gear finishing device, including a near-field ultrasonic cavitation system, a fluid shear system, and a polishing liquid circulation system. The near-field ultrasonic cavitation system includes an ultrasonic generator 1, a pressure Electric transducer 2, horn 3, upper tray 5, lower tray 7 and precision support 4; the ultrasonic generator 1 is connected to the piezoelectric transducer 2 through wires, and the piezoelectric transducer 2 and the horn 3 are connected by double-ended studs. The horn 3 is provided with a flange for fixing to the precision bracket. The horn 3 and the upper tray 5 are connected by bolts. The lower tray 7 is set under the upper tray 5, and the upper tray 7 A micro-gear 6 is provided, and the micro-gear 6 is connected to the fixture 8 by bolts;

[0035] The fluid shearing system comprises a polishing pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com