Hydrocarbon production system and method of use

a production system and hydrocarbon technology, applied in the direction of fluid removal, earthwork drilling and mining, borehole/well accessories, etc., can solve the problems of reduced daily production, inability to achieve continuous or more economical hydrocarbon production, and fluid blockage within the subsurface production tubing and surface flow line, etc., to achieve less expensive, prolong service life, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

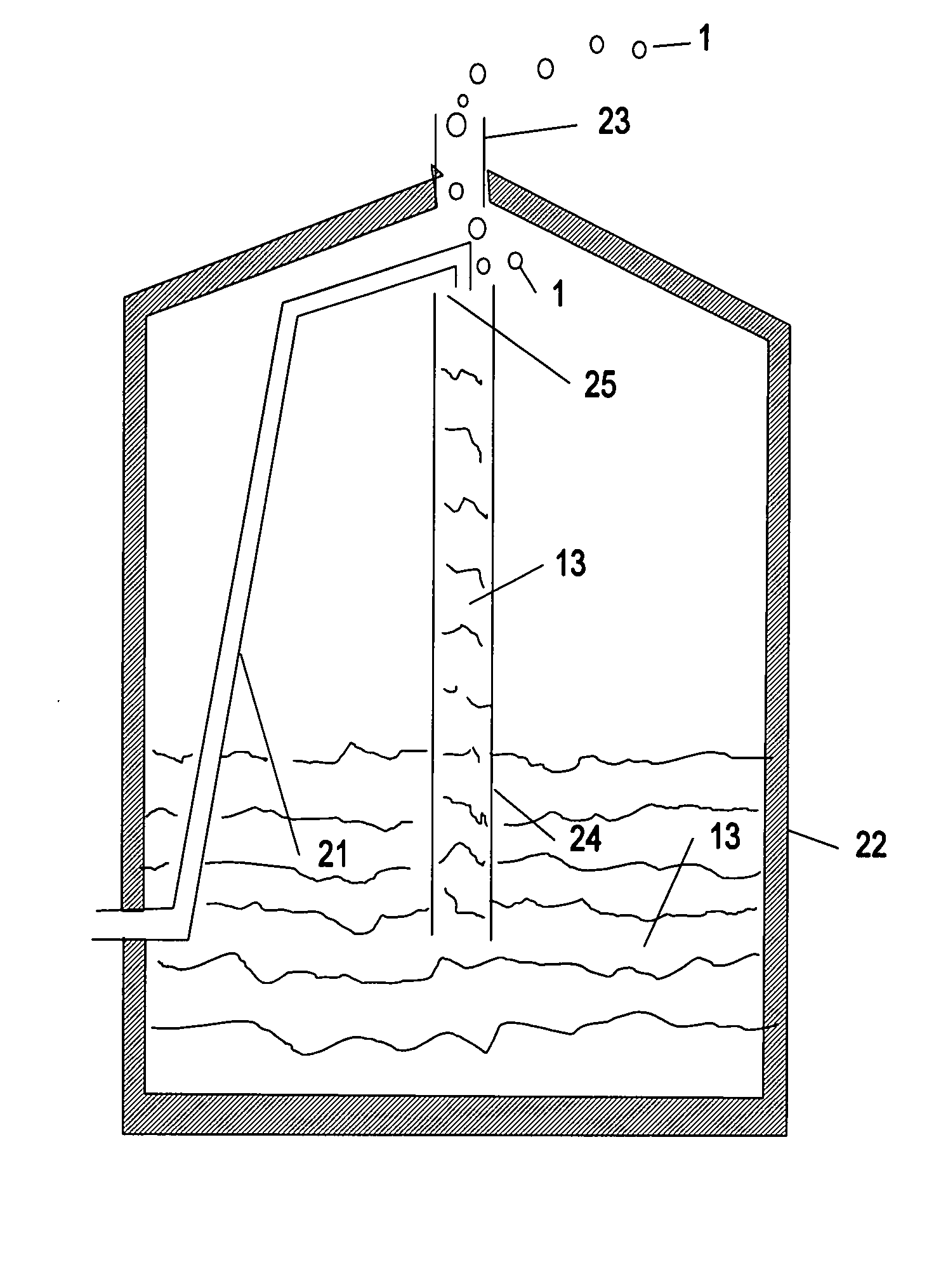

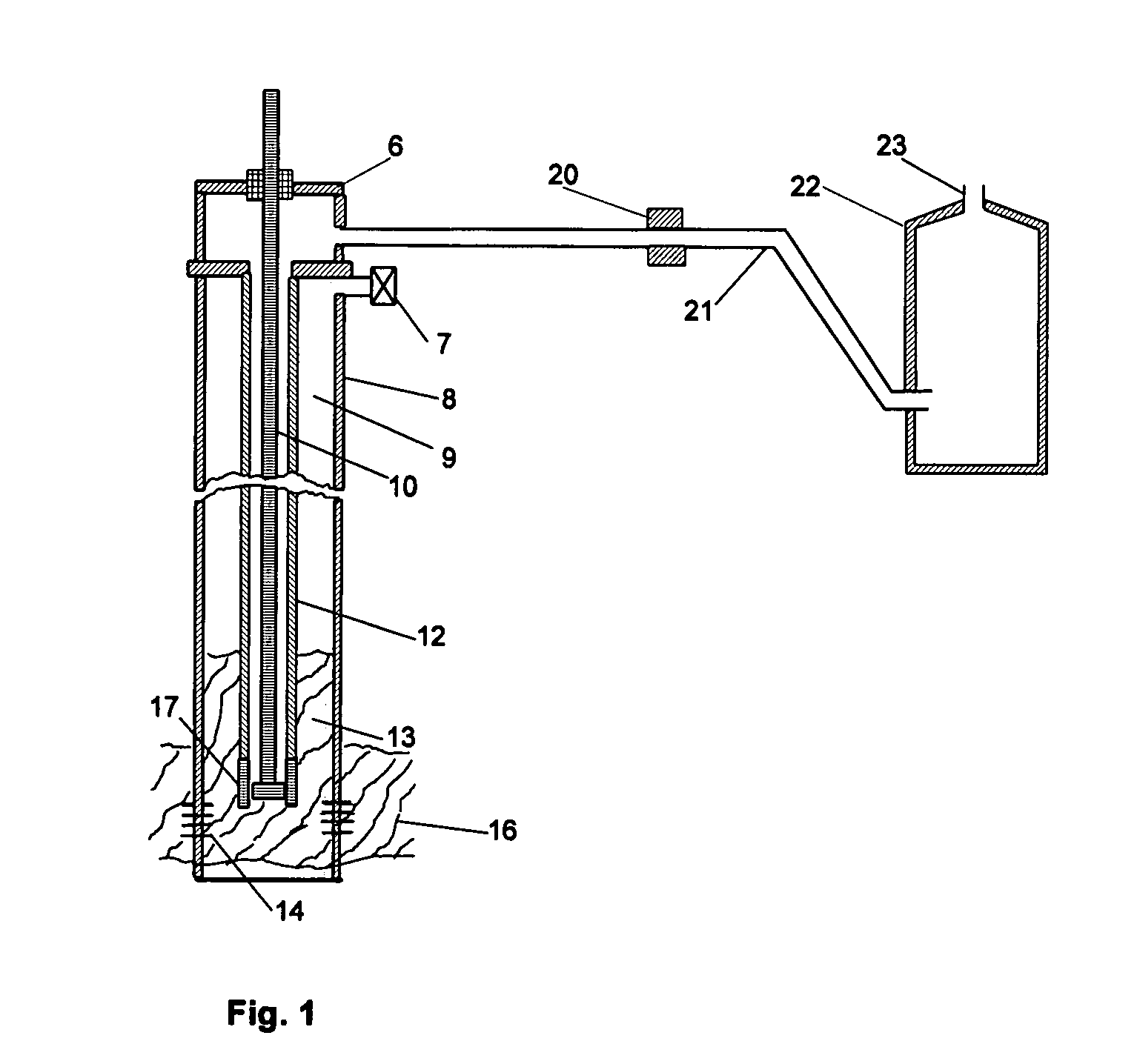

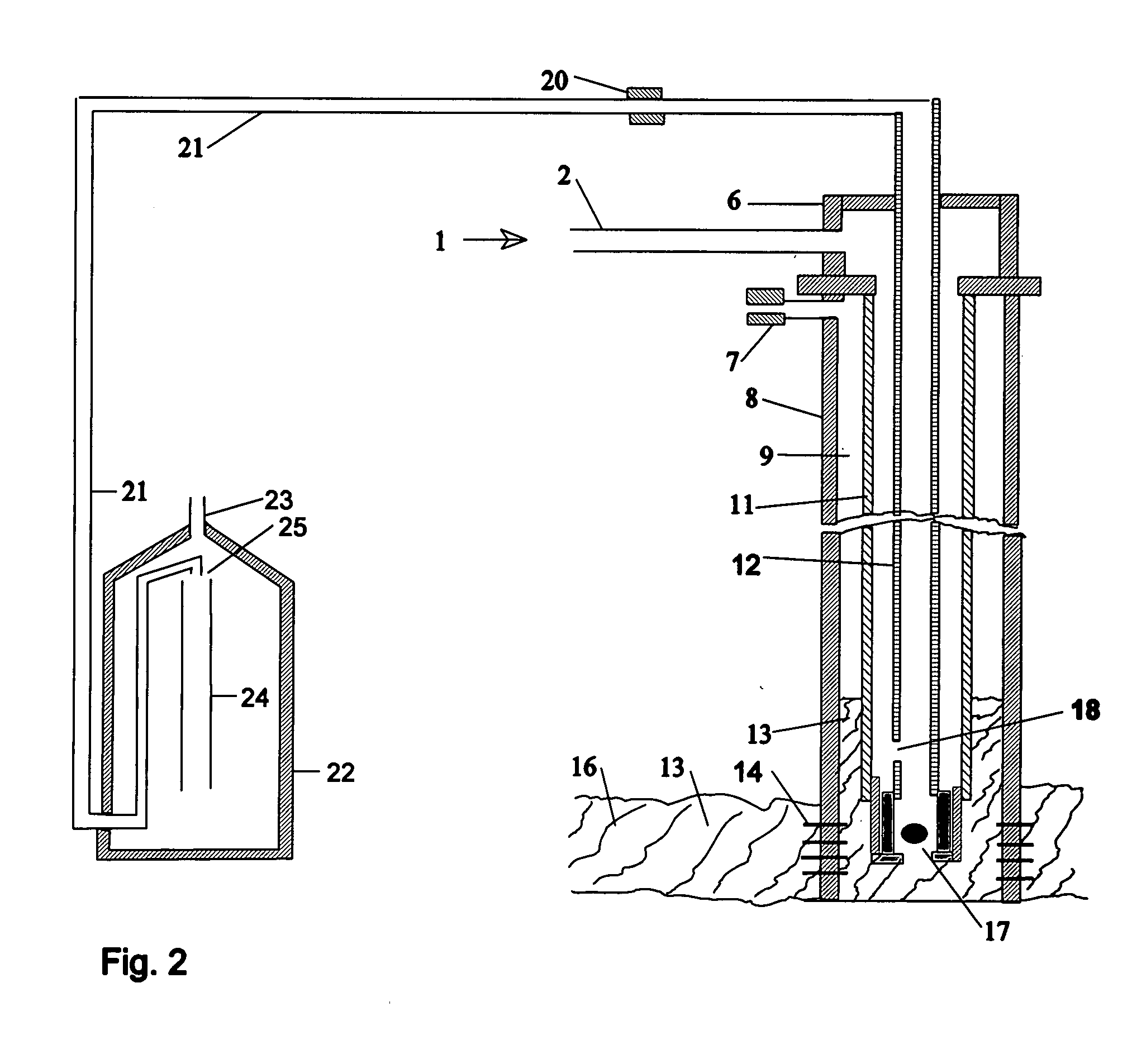

[0030]Referring initially to FIG. 1, a typical conventional oil well system includes a production casing indicated by reference numeral 8 which is placed into the earth. Within the casing 8 there is provided a subsurface production tubing string 12 which is basically a length of coiled tubing or lengths of conduit coupled together from a connection from wellhead 6 to subsurface production pump 17. The system may also include what is commonly known as sucker rods 10. In use, hydrocarbon fluid 13 is fed by means of subterranean hydrocarbon reservoir 16 pressure into well bore 9 through casing perforations 14 and pumped from well bore 9 by subsurface production pump 17, into and through subsurface hydrocarbon production tubing 12, into and through wellhead 6, into and through surface flow line 21, into and through optional surface check valve 20 and into hydrocarbon production fluid storage tank 22. Valve 7 is provided to vent casing gas. Optional surface check valve 20 may be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com