High-precision speed locker for multi-span bridge anti-seismic

A speed-locking, high-precision technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of low horizontal strength of multi-span bridges, achieve high sensitivity, enhanced sealing effect, and good reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

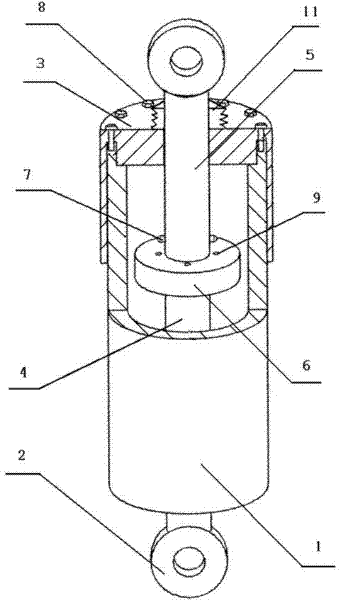

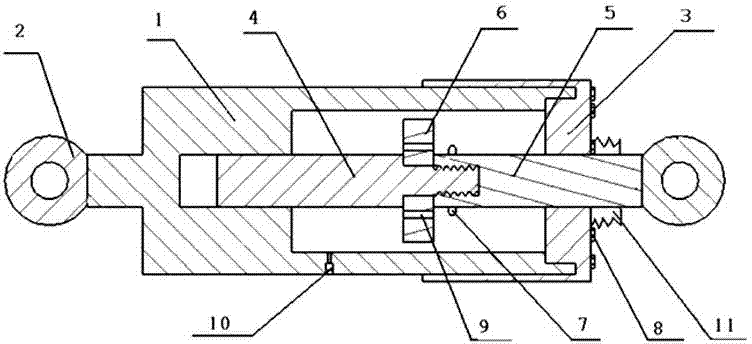

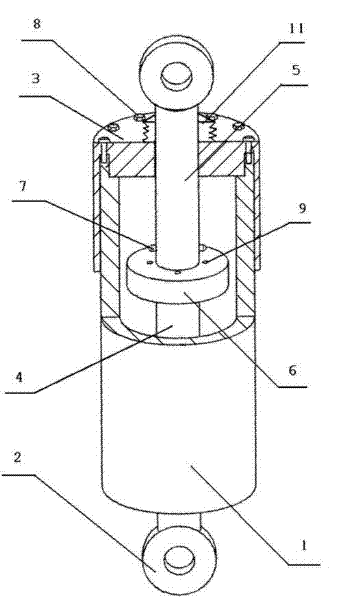

[0025] see figure 1 with figure 2 , The multi-span bridge anti-seismic high-precision speed locker includes a cylinder part, a piston part and a working material, the piston part and the cylinder part are assembled to form a whole, the working material is located in the cylinder, and the working material is a shear thickening fluid. The cylinder body part includes a cylindrical cylinder body 1 and an end cover, and a connecting seat 2 is installed at the outer end of the cylinder body 1 . The piston part includes a piston 6, a piston rod 4 and a connecting rod 5, one end of the piston rod 4 and one end of the connecting rod 5 are threadedly connected, and the other end of the connecting rod 5 extends outside the other end of the cylinder. The piston 6 is sleeved on the piston rod 4 , and the piston 6 is provided with an anti-skid bump 7 and a damping hole 9 .

[0026] The end cover is a cylindrical sealing cover 3, which is connected to the cylinder body 1 by bolts 8. The b...

Embodiment 2

[0029] see figure 1 with figure 2 , A dust cover 11 is installed on the outer side of the sealing cover 3, and the dust cover 11 is sleeved on the connecting rod 5.

[0030] The working material is a shear thickening gel.

[0031] Other structures are with embodiment 1.

[0032] In a dusty environment, installing the dust cover 11 on the high-precision speed locker can effectively prevent dust from entering the cylinder cavity, and prevent dust from reducing the performance of the shear thickening material.

Embodiment 3

[0034] The difference with Example 1 is:

[0035] A liquid injection hole 10 is provided on the side wall of the cylinder body 1. The diameter of the liquid injection hole is 6 mm, and a plunger is installed in the liquid injection hole 10 . See figure 2 . If the high-precision speed locker is used for a long time, liquid leakage will inevitably occur, resulting in a decrease in accuracy. At this time, the shear thickening material can be injected into the cylinder through the liquid injection hole 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com