Method for preparing composite material of stannic oxide/polyaniline

A technology of tin dioxide and composite materials, applied in the field of material science, can solve the problems of electrode capacity attenuation, loss of electrical contact of electrode particles, change of metal oxide stoichiometric ratio, etc., to achieve the effects of low cost, wide source and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

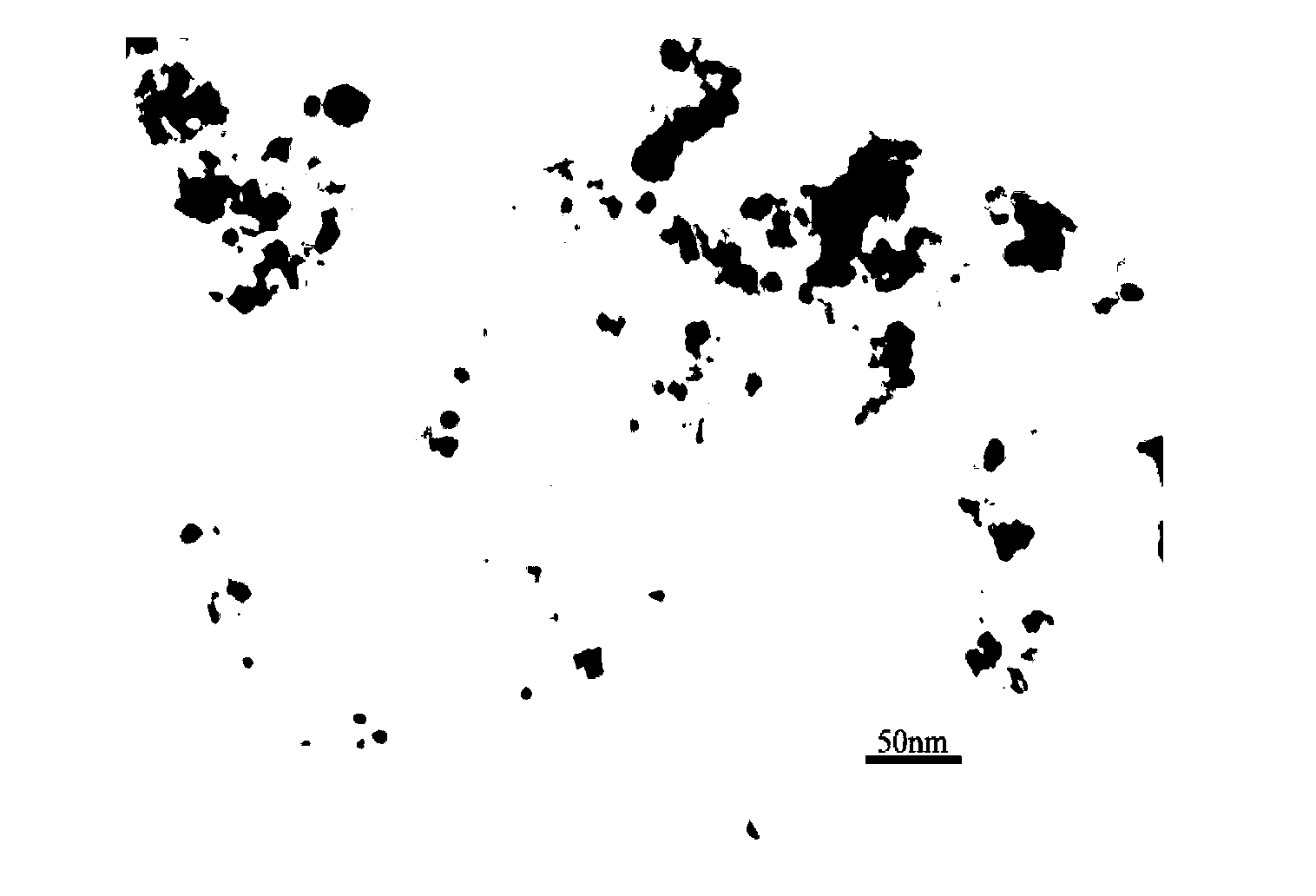

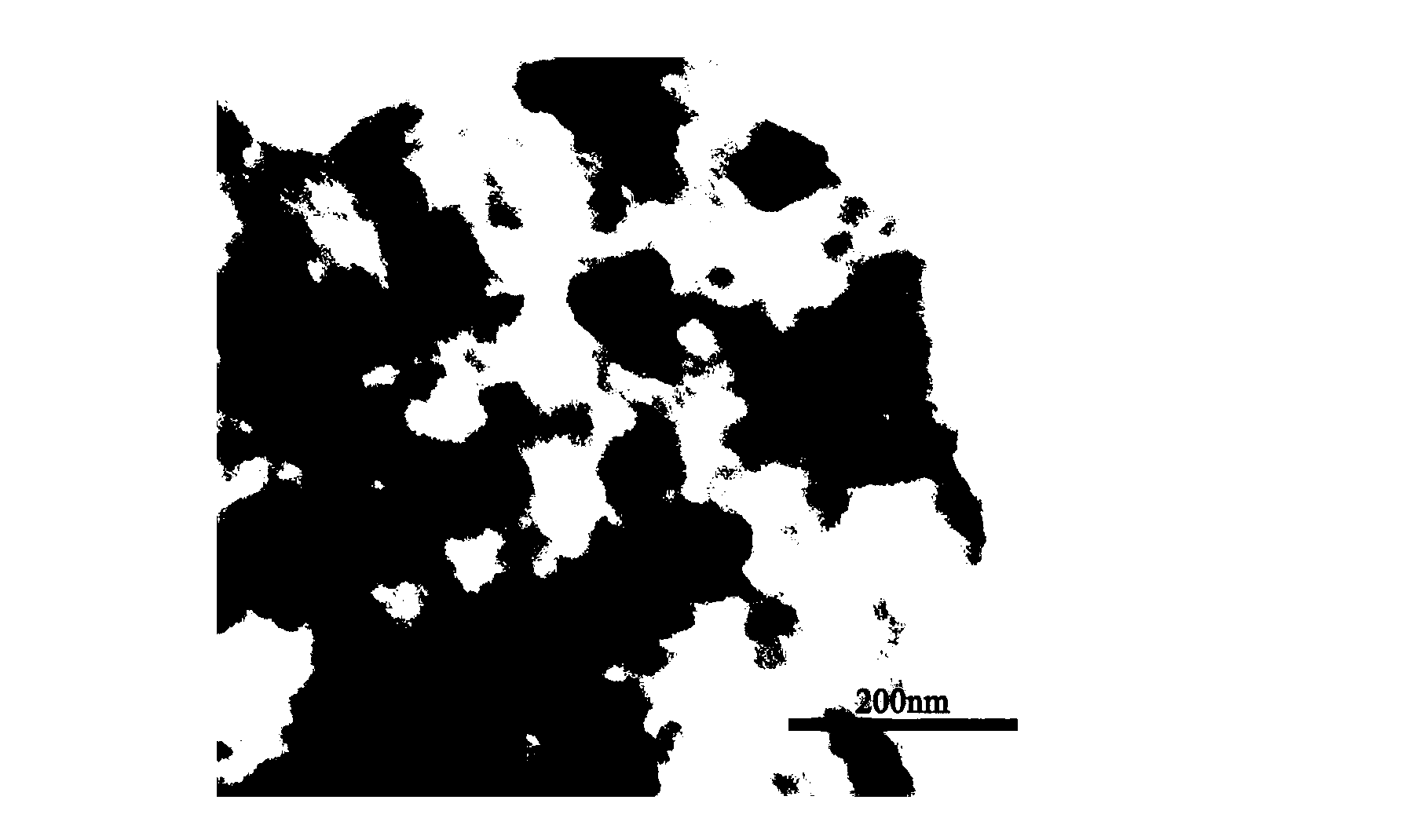

Image

Examples

Embodiment 1

[0029] Embodiment 1 prepares a kind of tin dioxide / polyaniline composite material, concrete steps are as follows:

[0030] Preparation of nano tin dioxide powder:

[0031] a. First, add 50ml of ethylene glycol into a 100ml four-necked flask, heat it to about 80°C and keep it at a constant temperature, add 13g of crystalline tin tetrachloride into the flask, and stir it magnetically for 5 minutes to obtain a colorless and transparent precursor solution.

[0032] b. Continue to heat the solution to 120°C for reaction, stir at medium speed for 5h, stop stirring and continue to react for 10h. Nitrogen gas was introduced into the flask, and the reaction temperature was kept at about 120°C. The water and hydrogen chloride generated during the reaction will volatilize in large quantities until a viscous tan gel is obtained.

[0033] c. The gel was aged at room temperature for 1 h, and then dried in a drying oven at 140° C. for 10 h to obtain a xerogel.

[0034] d. Finally, place t...

Embodiment 2

[0040] Embodiment 2 prepares a kind of tin dioxide / polyaniline composite material, concrete steps are as follows:

[0041] Preparation of nano tin dioxide powder:

[0042] a. First, add 30ml of ethylene glycol into a 100ml four-neck flask, heat it to about 80°C and keep it at a constant temperature, add 13g of crystalline tin tetrachloride into the flask, and stir it magnetically for 5 minutes to obtain a colorless and transparent precursor solution.

[0043] b. Continue to heat the solution to 120°C for reaction, stir at medium speed for 5h, stop stirring and continue to react for 10h. Nitrogen gas was introduced into the flask, and the reaction temperature was kept at about 120°C. The water and hydrogen chloride generated during the reaction will volatilize in large quantities until a viscous tan gel is obtained.

[0044] c. The gel was aged at room temperature for 1 h, and then dried in a drying oven at 140° C. for 15 h to obtain a xerogel.

[0045] d. Finally, place the...

Embodiment 3

[0051] Embodiment 3 prepares a kind of tin dioxide / polyaniline composite material, concrete steps are as follows:

[0052] Preparation of nano tin dioxide powder:

[0053] a. First add 40ml of ethylene glycol to a 100ml four-neck flask, heat it to about 80°C and keep it at a constant temperature, add 13g of crystalline tin tetrachloride to the flask, and stir it magnetically for 5 minutes to obtain a colorless and transparent precursor solution.

[0054] b. Continue to heat the solution to 120°C for reaction, stir at medium speed for 5h, stop stirring and continue to react for 10h. Nitrogen gas was introduced into the flask, and the reaction temperature was kept at about 120°C. The water and hydrogen chloride generated during the reaction will volatilize in large quantities until a viscous tan gel is obtained.

[0055] c. The gel was aged at room temperature for 1 h, and then dried in a drying oven at 140° C. for 20 h to obtain a xerogel.

[0056] d. Finally, place the xero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com