Method for preparing ethylene glycol monobutyl ether

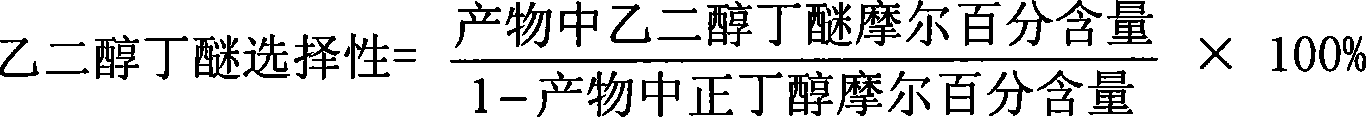

A technology of ethylene glycol butyl ether and n-butanol, which is applied in ether preparation, organic chemistry, etc., can solve the problems of long process route, high energy consumption and material consumption, and large equipment investment, and overcome the long process flow and product selectivity High, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the modified titanium-silicon molecular sieve in the example is: add 10 g of titanium-silicon molecular sieve synthesized according to the method disclosed in CN1301599A into 100 g of distilled water, stir and heat up to 65 ° C, add 1.1 g of Tween 80 and stir for 10 minutes, add 1.45 g aluminum isopropoxide and 1.3 g Siben 80, raise the temperature to 90°C and stir for 4 hours, pressurize to 5Kg / cm2, raise the temperature to 120°C, react at constant temperature and pressure for 24 hours, take out, wash and filter, and bake at 110°C Dry for 5 hours, and bake at 600°C for 6 hours to obtain the modified titanium-silicon molecular sieve.

[0017] In an embodiment, the hydrogen peroxide is 30% H 2 o 2 , analytically pure; ethylene, analytically pure; n-butanol, analytically pure. All three are commercially available.

[0018] In the embodiment, the reactor is a COF2 / 10 stainless steel reactor produced by Beijing Research Institute of Chemical Ind...

Embodiment 1

[0025] 100g titanium silicon molecular sieve, 887g n-butanol, 113g concentration of 30% H 2 o 2 Add in the reaction kettle that volume is 2L successively, and the molar ratio of n-butanol and hydrogen peroxide is 12 at this moment. After airtight, start stirring while raising the temperature, and stop heating when the temperature reaches 100°C.

[0026] Continuously feed ethylene into the reactor, control the pressure of the reactor to 2.5MPa, and control the temperature to 100°C by adjusting the amount of water fed into the heating coil of the reactor. After reacting for 0.5 h, the selectivity of ethylene glycol butyl ether was 100%, the conversion rate of n-butanol was 7.2%, and the utilization rate of hydrogen peroxide was 86.4%.

Embodiment 2

[0028] 5g titanium silicon molecular sieve, 907.4g n-butanol, 92.6g concentration of 30% H 2 o 2 Add in the reaction kettle that volume is 2L successively, and the molar ratio of n-butanol and hydrogen peroxide is 15 at this moment. After airtight, start stirring while raising the temperature, and stop heating when the temperature reaches 40°C.

[0029] Continuously feed ethylene into the reactor, control the pressure of the reactor to 3.0 MPa, and control the temperature to 40° C. by adjusting the amount of water fed into the heating coil of the reactor. After 10 hours of reaction, the selectivity of ethylene glycol butyl ether was 100%, the conversion rate of n-butanol was 4.8%, and the utilization rate of hydrogen peroxide was 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com