Method for preparing manganese molybdate/cobalt molybdate hierarchical heterostructure nanowires

A technology of manganese molybdate nanometer and heterogeneous structure, which is applied in chemical instruments and methods, crystal growth, electrolytic capacitors, etc., and can solve problems such as inability to provide energy and power density, low specific capacitance of supercapacitors, and decline in specific capacitance , to achieve the effects of facilitating market promotion, reducing energy consumption, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

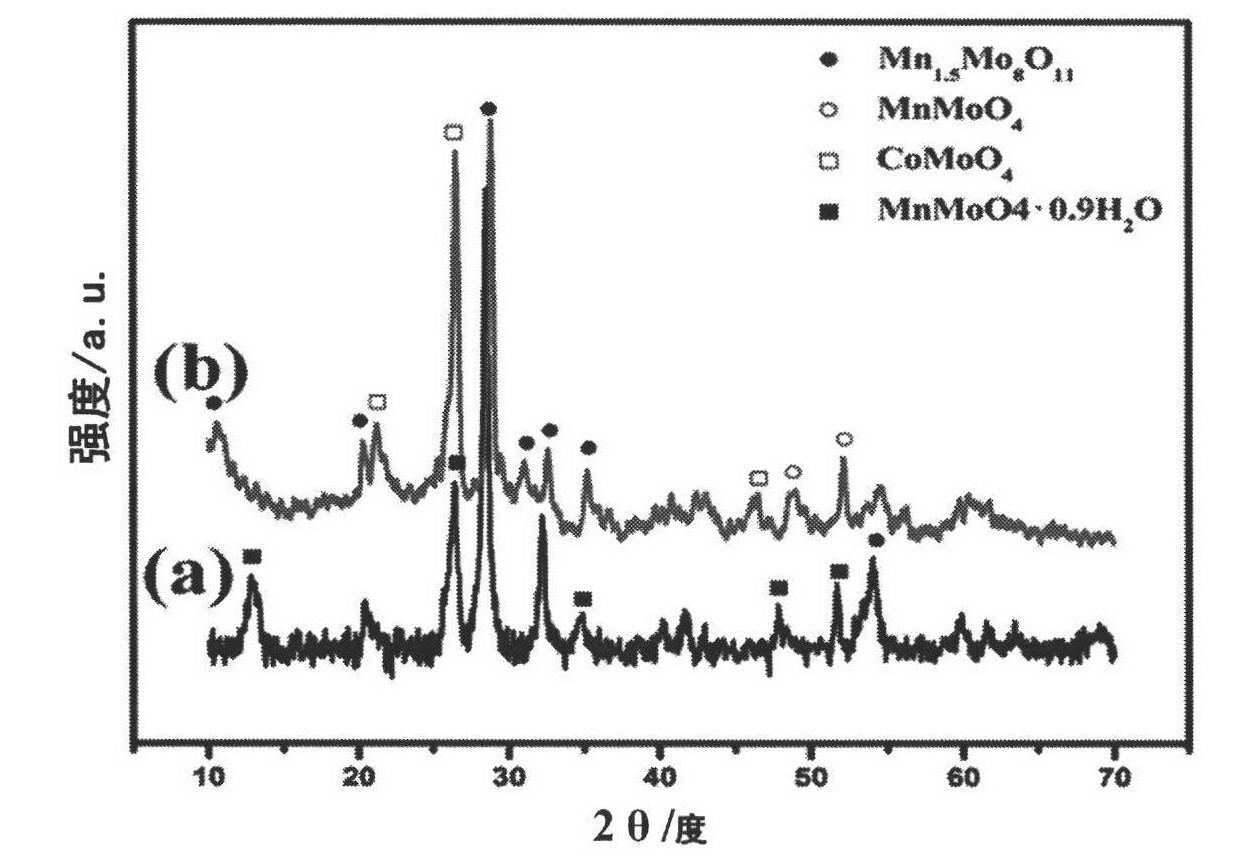

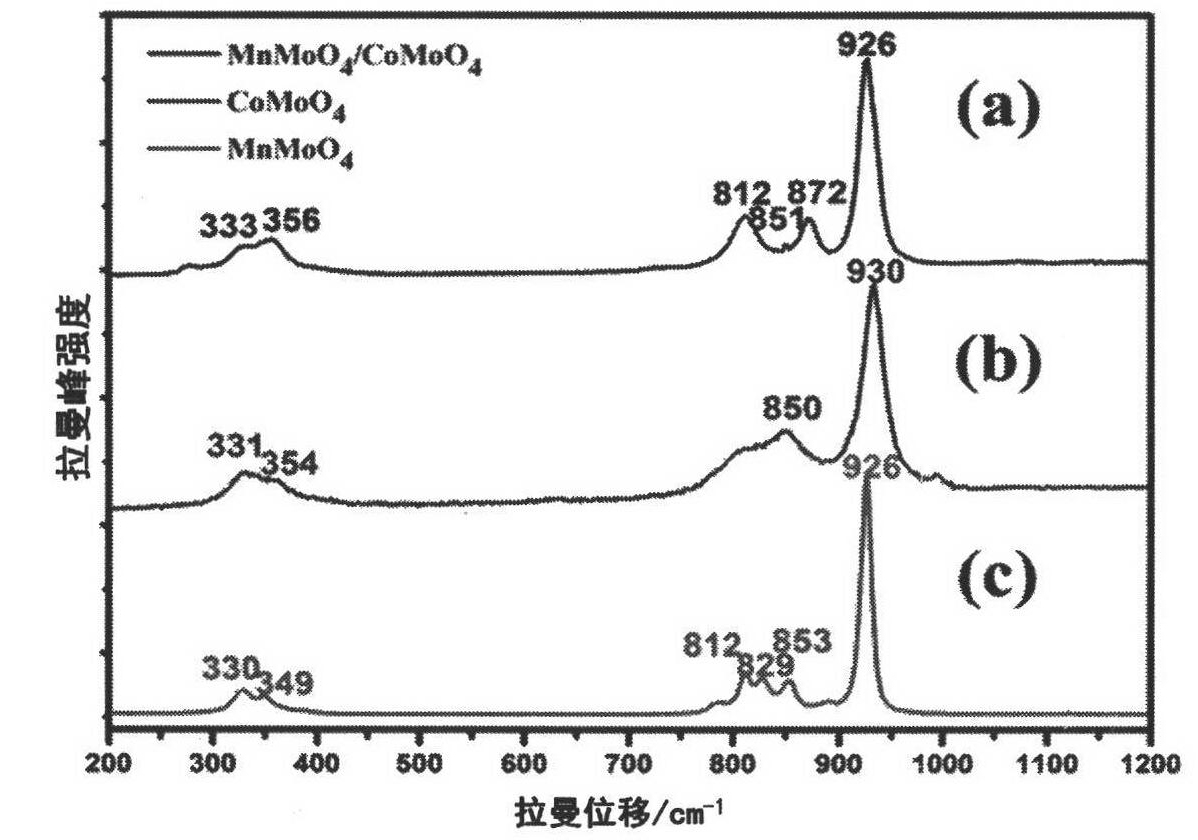

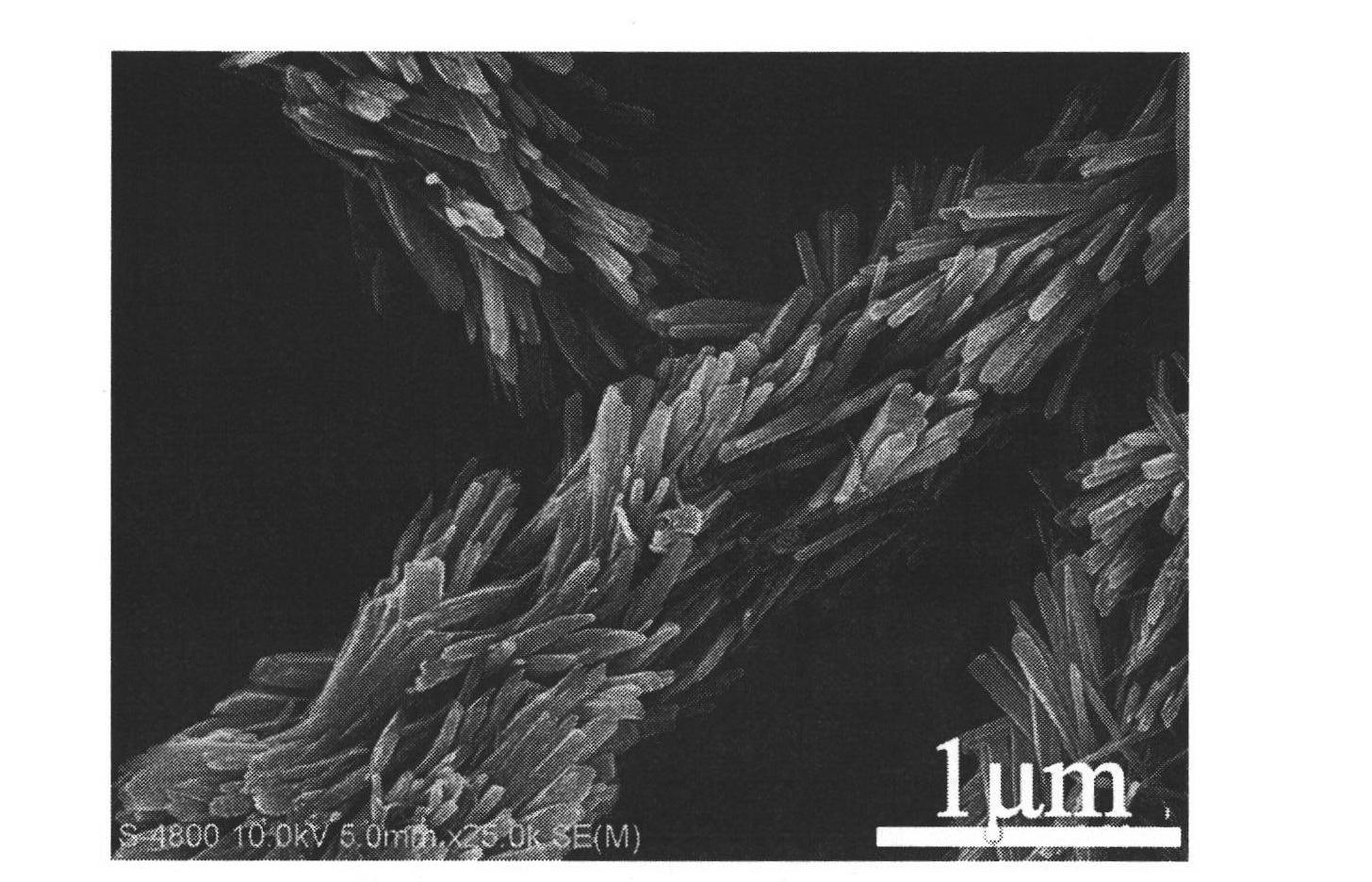

[0035] A method for preparing manganese molybdate / cobalt molybdate graded heterostructure nanowires, comprising the steps of:

[0036] 1) Prepare 0.5mol / L NaMoO 4 Aqueous solution and 0.5mol / L MnCl 2 Aqueous solution, NaMoO as prepared 4 Aqueous solution: MnCl 2 Aqueous solution: CTAB (cetyltrimethylammonium bromide): n-butanol: isooctane=1.39ml: 1.39ml: 1.56g: 1.6ml: 9ml ratio batching, join in the reactor, utilize microemulsion method, using a magnetic stirrer to stir for 1 hour, aging for 12 hours, and using ethanol to repeatedly centrifuge and wash to prepare manganese molybdate nanorods with a diameter of 300-500 nm and a length of about 10 microns, which are set aside;

[0037] 2) The manganese molybdate nanorod obtained in step 1) is used as the backbone material, and the manganese molybdate nanorod of 0.2 mmol is added to 40 ml of deionized water, stirred at room temperature with a magnetic stirrer for 10 minutes, and then placed in an ultrasonic cleaner Sonicate a...

Embodiment 2

[0042] A method for preparing manganese molybdate / cobalt molybdate graded heterostructure nanowires, comprising the steps of:

[0043] 1) Prepare 0.5mol / L NaMoO 4 Aqueous solution and 0.5mol / L MnCl 2 Aqueous solution, NaMoO as prepared 4 Aqueous solution: MnCl 2 Aqueous solution: CTAB: n-butanol: isooctane = 1.39ml: 1.39ml: 1.56g: 1.6ml: 9ml, add to the reactor, use the microemulsion method, stir for 2 hours with a magnetic stirrer, and age After 12 hours, use ethanol to repeatedly centrifuge and wash to prepare manganese molybdate nanorods with a diameter of 300-500 nm and a length of about 10 microns, and set aside;

[0044] 2) The manganese molybdate nanorod obtained in step 1) is used as the backbone material, and the manganese molybdate nanorod of 0.2 mmol is added to 40 ml of deionized water, stirred at room temperature with a magnetic stirrer for 15 minutes, and then placed in an ultrasonic cleaner Sonicate at a frequency of 40Hz for 0.2 hours to obtain a nearly col...

Embodiment 3

[0049] A method for preparing manganese molybdate / cobalt molybdate graded heterostructure nanowires, comprising the steps of:

[0050] 1) Prepare 0.5mol / L NaMoO 4 Aqueous solution and 0.5mol / L MnCl 2 Aqueous solution, NaMoO as prepared 4 Aqueous solution: MnCl 2 Aqueous solution: CTAB: n-butanol: isooctane = 1.39ml: 1.39ml: 1.56g: 1.6ml: 9ml, add to the reactor, use the microemulsion method, stir for 1 hour with a magnetic stirrer, and age After 12 hours, use ethanol to repeatedly centrifuge and wash to prepare manganese molybdate nanorods with a diameter of 300-500 nm and a length of about 10 microns, and set aside;

[0051] 2) The manganese molybdate nanorod obtained in step 1) is used as the backbone material, and the manganese molybdate nanorod of 0.2 mmol is added to 40 ml of deionized water, stirred at room temperature with a magnetic stirrer for 10 minutes, and then placed in an ultrasonic cleaner Ultrasonic treatment at a frequency of 50 Hz for 0.2 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com