Method for preparing nano ternary composite lithium ion anode material by utilizing microemulsion

A positive electrode material and ternary composite technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as difficult to control precipitation morphology and size, and achieve good cycle stability, The effect of high discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

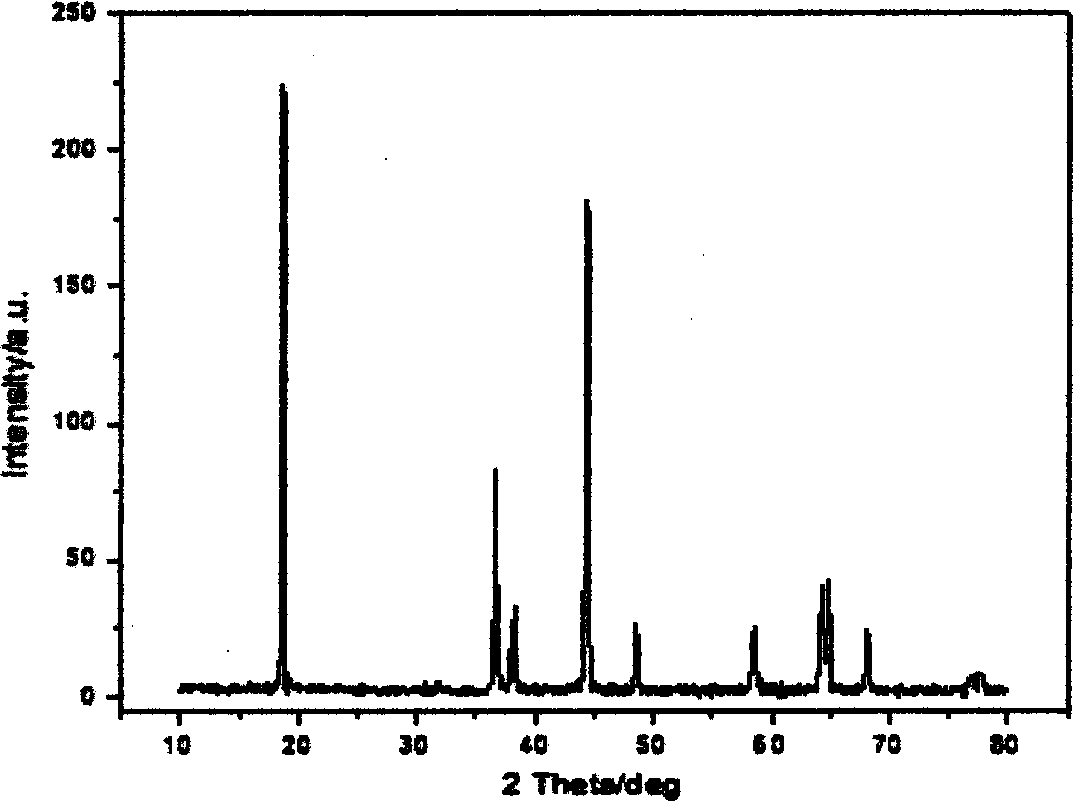

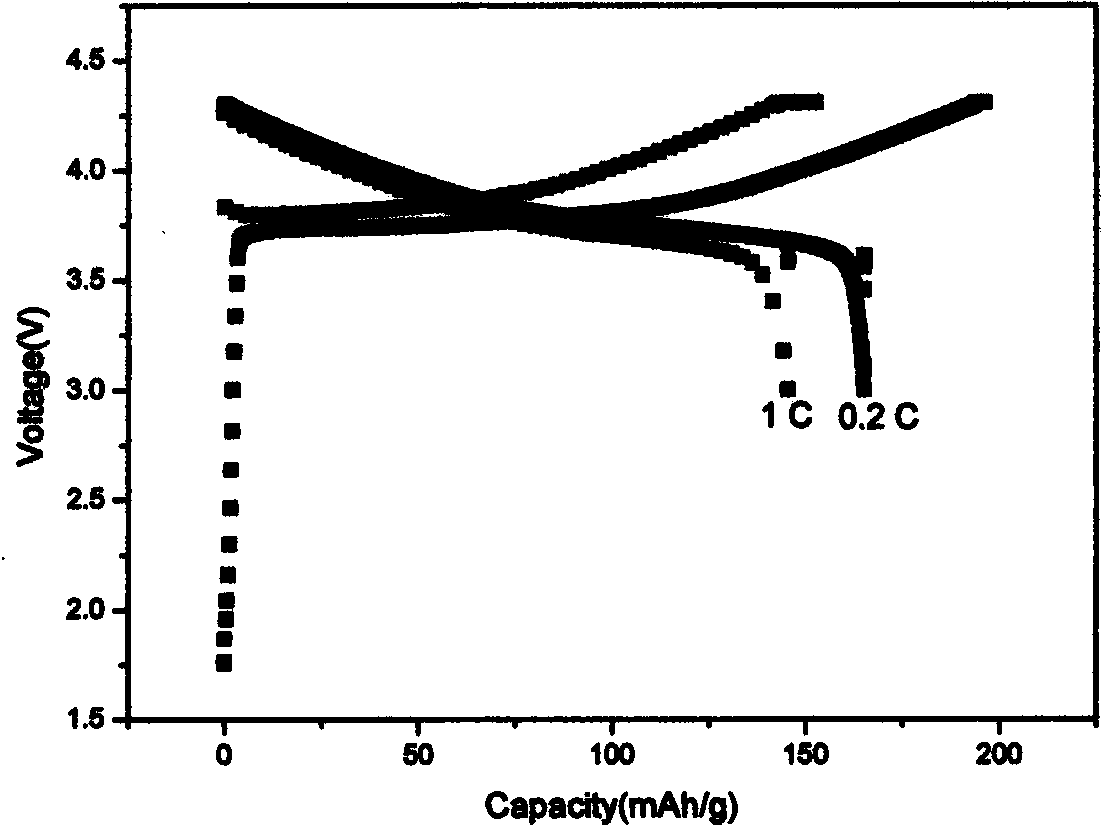

[0025] Nano LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Taking material synthesis as an example, the synthesis method includes the following steps:

[0026] 1. Evenly mix the surfactant Triton X-100 and the co-surfactant n-butanol and cyclohexane to make an emulsifier, and divide the emulsifier into the first equal part emulsifier and the second equal part emulsification agent;

[0027] 2. Dissolve nickel salt, cobalt salt and manganese salt in deionized water, stir evenly, and prepare an aqueous solution with a concentration of 0.5mol / L;

[0028] 3. Mix the aqueous solution with a concentration of 0.5mol / L in step 2 with the first aliquot emulsifier in step 1, stir evenly, and stir at room temperature for 20min to make a nickel-cobalt-manganese salt microemulsion;

[0029] Four, preparation concentration is the alkaline solution of 2mol / L, and adding concentration is the complexing agent of 0.25mol / L in alkaline solution, makes complexing agent alkaline solution;

[0030] Five, the comp...

Embodiment 2

[0038] Nano LiNi 0.4 co 0.2 mn 0.4 o 2 Taking material synthesis as an example, the synthesis method includes the following steps:

[0039] 1. Evenly mix the surfactant Triton X-100 and the co-surfactant n-butanol and cyclohexane to make an emulsifier, and divide the emulsifier into the first equal part emulsifier and the second equal part emulsification agent;

[0040] 2. Dissolve nickel salt, cobalt salt and manganese salt in deionized water, stir evenly, and prepare an aqueous solution with a concentration of 2.5mol / L;

[0041] 3. The aqueous solution with a concentration of 2.5mol / L in step 2 is mixed with the first aliquot emulsifier in step 1, stirred evenly, and stirred at room temperature for 60min to make a nickel-cobalt-manganese salt microemulsion;

[0042] Four, preparation concentration is the alkaline solution of 10mol / L, and adding concentration is the complexing agent of 3mol / L in alkaline solution, makes complexing agent alkaline solution;

[0043] Five,...

Embodiment 3

[0051] Nano LiNi 0.5 co 0.2 mn 0.3 o 2 Taking material synthesis as an example, the synthesis method includes the following steps:

[0052] 1. Evenly mix the surfactant Triton X-100 and the co-surfactant n-butanol and cyclohexane to make an emulsifier, and divide the emulsifier into the first equal part emulsifier and the second equal part emulsification agent;

[0053] 2. Dissolve nickel salt, cobalt salt and manganese salt in deionized water, stir evenly, and prepare an aqueous solution with a concentration of 2.0mol / L;

[0054] 3. Mix the aqueous solution with a concentration of 2.0mol / L in step 2 with the first aliquot emulsifier in step 1, stir evenly, and stir at room temperature for 20min to make a nickel-cobalt-manganese salt microemulsion;

[0055] Four, preparation concentration is the alkaline solution of 3mol / L, and adding concentration is the complexing agent of 1mol / L in alkaline solution, makes complexing agent alkaline solution;

[0056] Five, the complex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com