High-hardness water-borne double-component wood-ware varnish with high wear resistance and preparing method thereof

A water-based two-component, wood varnish technology, applied in the field of wood varnish, can solve the problems of little improvement in wear resistance and scratch resistance, increased VOC content, affecting the transparency of the paint film, etc., to achieve excellent coating effect and application range, improve Abrasion resistance, fine touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

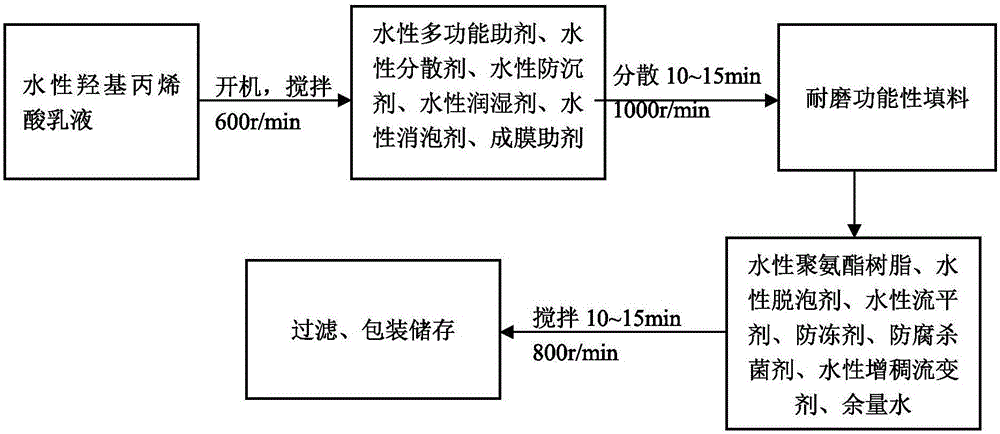

[0025] The preparation method of the high hardness and high wear resistance water-resistant two-component wood varnish of the present invention comprises the following steps, wherein the technological process of main agent A is as follows figure 1 Shown:

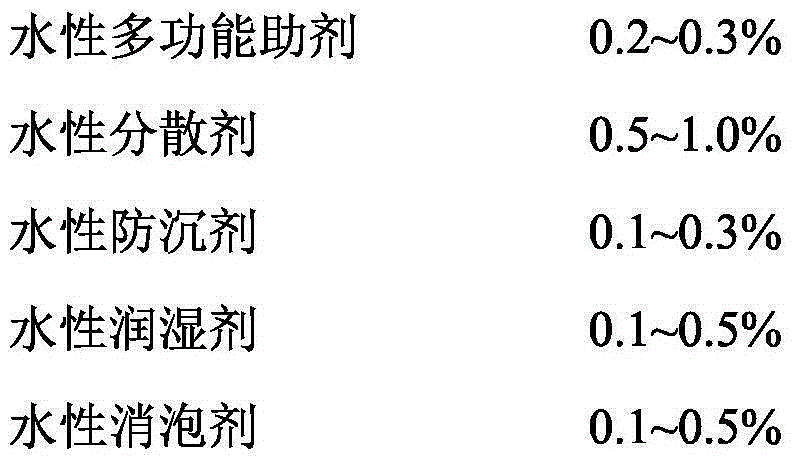

[0026] (1). According to the formula amount in Table 1, put the water-based hydroxyacrylic acid emulsion into the dispersion tank, and add the water-based multifunctional additive, water-based dispersant, water-based anti-sedimentation agent, water-based wetting agent, Water-based defoamer and film-forming aid, after adding, disperse at 1000r / min for 10-15min;

[0027] (2). Add water-based wear-resistant functional filler under stirring state, and disperse at 1200r / min for 30min to fineness≤25um after adding;

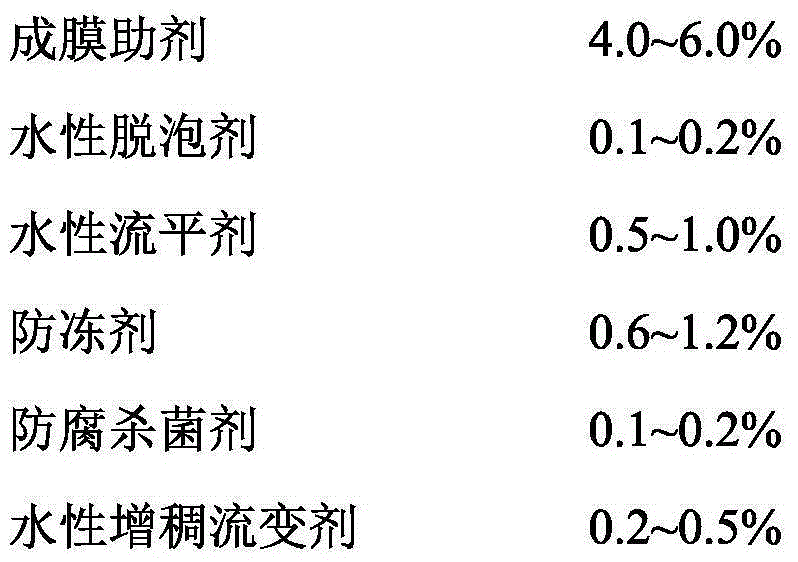

[0028] (3). Add water-based polyurethane resin, water-based defoamer, water-based leveling agent, antifreeze, anti-corrosion and fungicide, water-based thickening rheological agent and the rest of water in 800r / min s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com