Salt-storage sustained-release snow-melt deicer and preparation method thereof

A slow-release, deicing agent technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of long release time and limited release of deicing agents, achieve large amount of ice melting, simple preparation process, and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

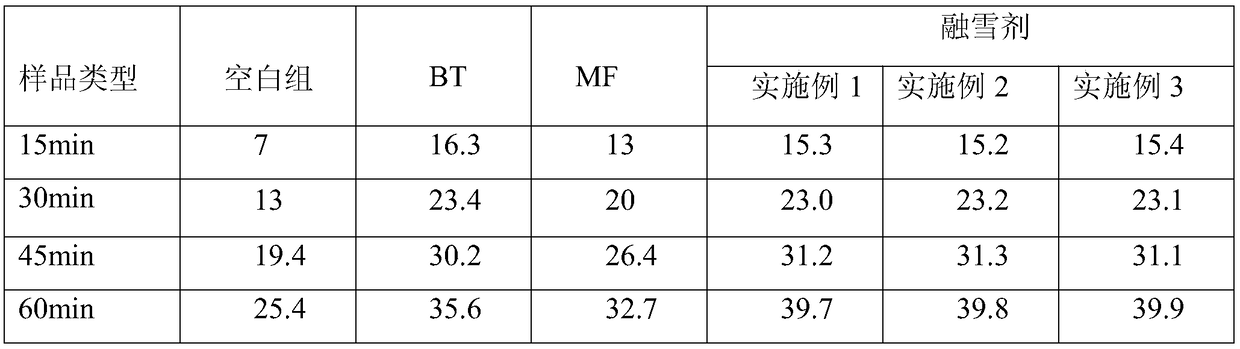

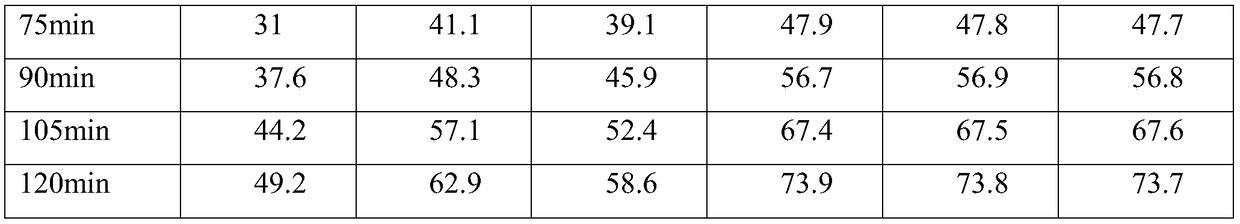

Examples

Embodiment 1

[0026] A salt-storage slow-release snowmelting and deicing agent, comprising the following ingredients: 128g of slow-release inorganic salts, 33g of isopropanol and 40g of polymer monomers in the encapsulating polymer; Calcium chloride saturated solution 120g, 8g diatomaceous earth, 0.8g nano silicon dioxide, 3.8g OP-10 and 180mL absolute ethanol; the encapsulation polymer includes 1g acrylic acid, 18g methyl acrylate, 14g butyl acrylate, 7g styrene , 1gKH570, 0.8gAIBN, 2g isopropanol, 2g triethylamine and 5g water.

[0027] The preparation method of the salt-storage slow-release snow melting and deicing agent comprises the following steps:

[0028] (1) prepare 120g antifreezing calcium chloride saturated solution;

[0029] (2) Dissolve 8g of diatomite, 0.8g of nano-silica, and 3.8g of OP-10 in a flask previously filled with 180mL of absolute ethanol, and place the flask in a 60°C water bath with a polytetrafluoroethylene stirring rod Stir evenly to obtain a diatomite suspen...

Embodiment 2

[0034]A salt-storage slow-release snow-melting and deicing agent, comprising the following ingredients: 175g of slow-release inorganic salts, 65g of propylene glycol methyl ether and 50g of polymer monomers in the encapsulating polymer; Sodium chloride saturated solution 136g, 10g diatomaceous earth, 1.2g nano silicon dioxide, 4.3gOP-10 and 220mL absolute ethanol; The said wrapping polymer comprises 1.5g acrylic acid, 22g methyl acrylate, 18g butyl acrylate, 8.5g Styrene, 2g KH570, 1.3g AIBN, 65g propylene glycol methyl ether, 3g triethylamine and 10g water.

[0035] The preparation method of the salt-storage slow-release snow melting and deicing agent comprises the following steps:

[0036] (1) prepare 136g antifreezing sodium chloride saturated solution;

[0037] (2) Dissolve 10g of diatomite, 1.2g of nano-silica, and 4.3g of OP-10 in a flask previously filled with 220mL of absolute ethanol, and place the flask in a 60°C water bath with a Teflon stirring rod Stir evenly to...

Embodiment 3

[0042] A salt-storage slow-release snowmelting and deicing agent, comprising the following ingredients: 158.2g of slow-release inorganic salts, 45.2g of isopropanol and 45.2g of polymer monomers in the encapsulating polymer; the slow-release inorganic salts include anti- 110g of frozen magnesium chloride saturated solution, 9g of diatomaceous earth, 1g of nano-silica, 4g of OP-13 and 200mL of absolute ethanol; , 1.5g KH570, 0.9g AIBN, 2.5g isopropanol, 2.5g triethylamine and 7.5g water.

[0043] The preparation method of the salt-storage slow-release snow melting and deicing agent comprises the following steps:

[0044] (1) prepare 110g antifreeze magnesium chloride saturated solution;

[0045] (2) Dissolve 9g of diatomite, 1g of nano-silica, and 4g of OP-13 in a flask previously filled with 200mL of absolute ethanol, and place the flask in a 60°C water bath and stir evenly with a Teflon stirring rod , to obtain a diatomite suspension modified by nano-silica;

[0046] (3) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com