Self-emulsifying aqueous epoxide resin paint and method for producing the same

A technology of water-based epoxy resin and epoxy resin coating, applied in the direction of epoxy resin coating, coating, latex paint, etc., can solve the problems of poor flexibility and water resistance of cured coating film, and low filling ratio of water-based epoxy resin, etc. Achieve the effect of improving hydrophilicity and brittleness, good storage stability and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Self-emulsifying waterborne epoxy resin coating provided by the invention, its preparation method may further comprise the steps:

[0030] a. With a molar ratio of 1:1 to 1:2 alkoxy-terminated polyether and thionyl chloride as raw materials, N,N-dimethylformamide as a catalyst, stirring and reacting at 60 to 80°C to obtain Chlorine-terminated alkoxy-terminated polyethers;

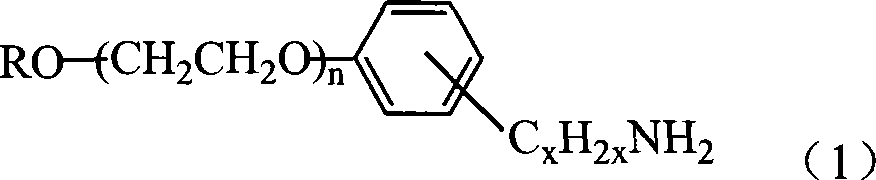

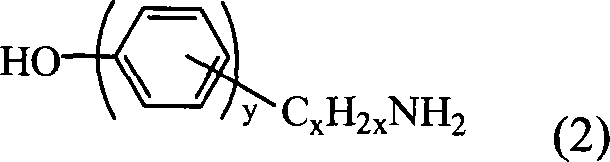

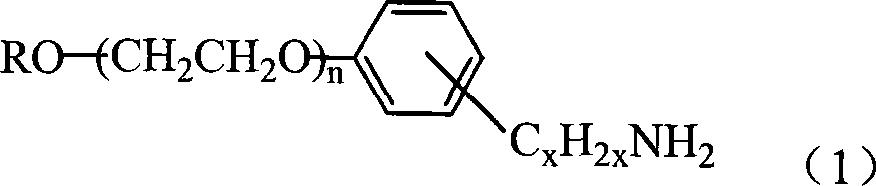

[0031] b. After mixing hydroxyphenyl fatty amine, sodium hydroxide and tetrabutylammonium bromide in a molar ratio of 1 to 2: 1.1 to 6: 0.02 to 0.08, add chlorine-terminated alkoxy polyether, and Stir and react at 60-80°C, then extract, filter and distill off the solvent to obtain α-amino-ω-alkyl polyether;

[0032] c. Use propylene glycol methyl ether with a molar ratio of 8 to 12 as a solvent, mix epoxy resin and α-amino-ω-alkyl polyether in a molar ratio of 1 to 1.5: 0.6 to 1.5, and mix them uniformly at 60 to 80 The reaction was stirred at ℃, and then the solvent was distilled off. Described h...

Embodiment 1

[0038] Add 0.1mol of polyethylene glycol monomethyl ether and 0.6ml (0.01mol) of N,N-dimethylformamide (DMF) into a 250ml three-necked flask, heat up to 40°C with an oil bath while stirring, and then 9 ml (0.12 mol) of thionyl chloride was added dropwise within 20 min, and then the stirring reaction was continued at 80° C. for 8 hours. SO produced during the reaction 2 , HCl gas is absorbed with lye. After the reaction solution was cooled, it was washed with saturated brine, the crude product was collected, dried with anhydrous potassium carbonate and adjusted to neutrality, and then the filtrate was collected by filtration to obtain chlorine-terminated polyethylene glycol monomethyl ether.

[0039] Add 0.1 mol of hydroxybenzylamine, 0.4 mol of NaOH and 0.84 g of TBAB into a 250 ml three-necked flask, stir and mix evenly at room temperature, and then add 0.1 mol of chlorine-terminated polyethylene glycol monomethyl ether. At the same time, the mixture was heated to 60° C. wi...

Embodiment 2

[0042] Add 0.1mol of polyethylene glycol monomethyl ether and 1.2ml (0.02mol) of N,N-dimethylformamide (DMF) into a 250ml three-necked flask, heat up to 40°C with an oil bath while stirring, and then 12ml (0.16mol) of thionyl chloride was added dropwise within 25min, and then the stirring reaction was continued at 60°C for 30 hours. SO produced during the reaction 2 , HCl gas is absorbed with lye. After the reaction solution was cooled, it was washed with saturated brine, the crude product was collected, dried with anhydrous potassium carbonate and adjusted to neutrality, and then the filtrate was collected by filtration to obtain chlorine-terminated polyethylene glycol monomethyl ether.

[0043]Add 0.05mol hydroxybenzylamine, 0.25mol NaOH and 0.49g TBAB into a 250ml three-necked flask, stir and mix evenly at room temperature, and then add 0.05mol of chlorine-terminated polyethylene glycol monomethyl ether. At the same time, the mixture was heated to 80° C. with an oil bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com