Plate mop and mop bucket

The technology of a flat mop and a mop bucket is applied in the field of ground sanitation and cleaning appliances, and can solve the problems of difficult production, time-consuming and laborious operation, and large volume of the bucket body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

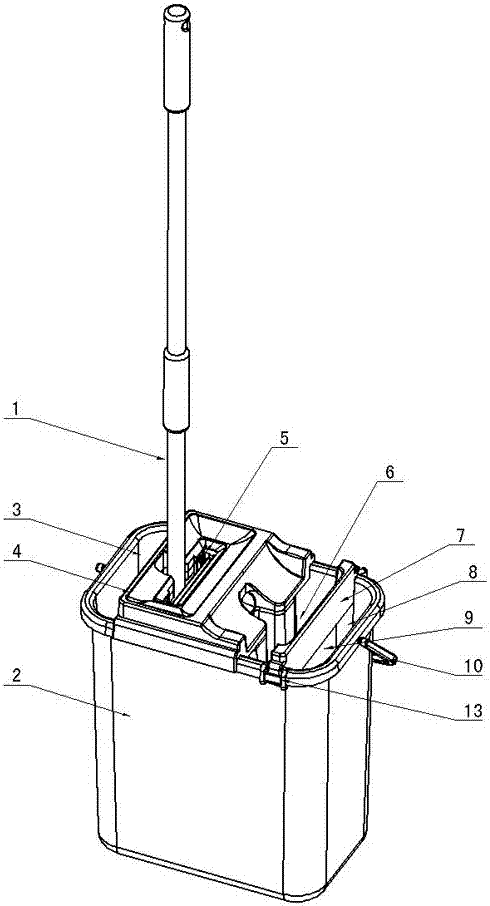

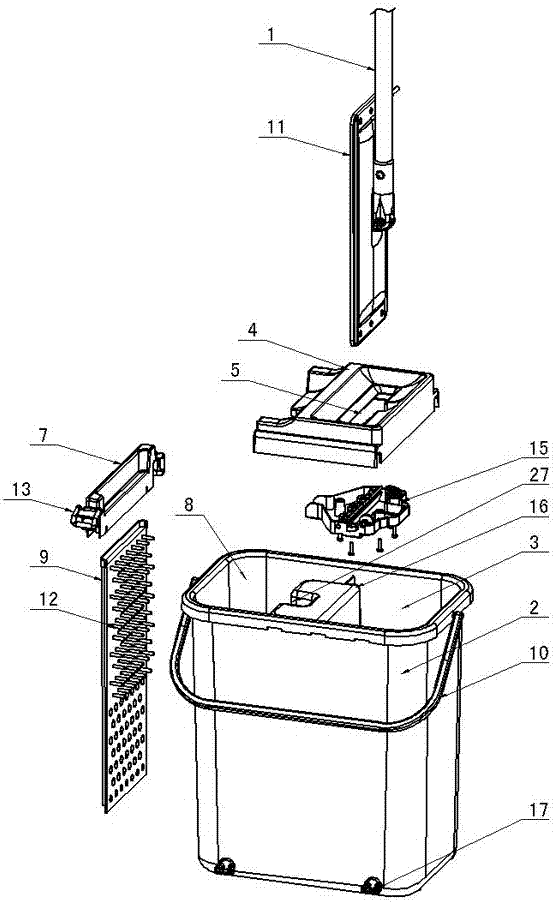

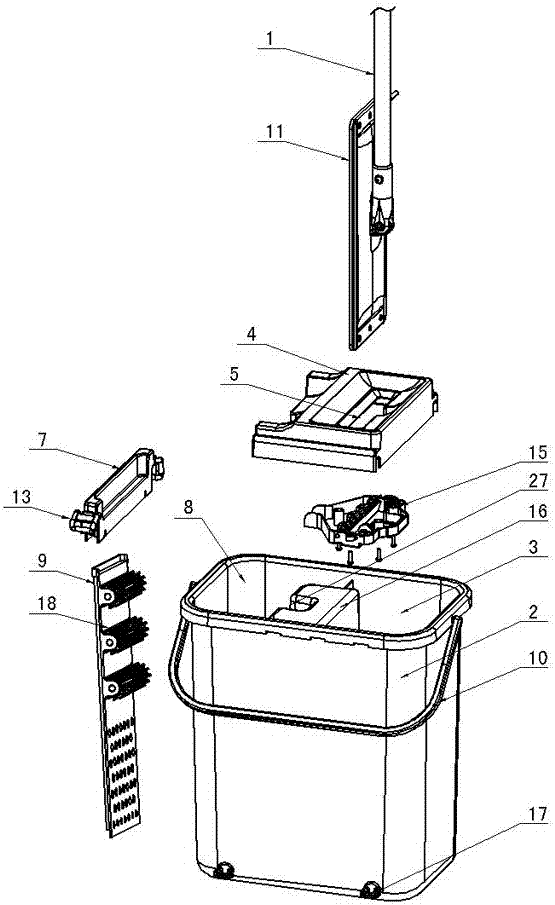

[0045] Figure 1 to Figure 5 Shown, for the present invention creates the first kind of specific embodiment of flat mop and mop bucket, it comprises flat mop, mop bucket 2, and flat mop 11 is movably connected with flat mop 11 below the mop bar 1 of flat mop, is provided with on flat mop 11 There is a mop, and the mop bucket 2 is provided with a water squeezing chamber 3 and a cleaning chamber 8 which are separated from each other, a water squeezing device is installed on the water squeezing chamber 3, and a cleaning device is installed in the cleaning chamber 8.

[0046] The cleaning device includes a cleaning fixture 7, a cleaning shelf 9, and a cleaning assembly. The cleaning fixture 7 is fixed on the mouth of the mop bucket 2 by means of buckles 13 and is provided with a cleaning port 6 for the flat mop 11 to move up and down. , the cleaning fixture 7 can also be fixed in other ways, the cleaning shelf 9 is fixed in the cleaning chamber 8 of the mop bucket 2 through the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com