Hollow filter stick and production method thereof

A manufacturing method and filter rod technology, which are applied in the directions of smoke oil filter element, application, tobacco, etc., can solve the problems of unsightly appearance of the end face and difficult forming, and achieve the effects of good smoke condensation effect, beautiful appearance and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

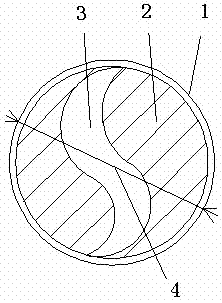

[0034] Embodiment 1: as figure 1 The hollow filter rod shown is formed by wrapping the hollow filter element 2 with forming paper 1, the length is 100-120mm, the outer circumference of the cross section is 16-18mm, and the hollow filter element has an axial hole extending along the length of the filter rod inside. 5. The cross-section of the axial hole 5 is S-shaped, and the cross-sectional area of the axial hole 5 accounts for 35-45% of the cross-sectional area of the entire filter rod.

Embodiment 2

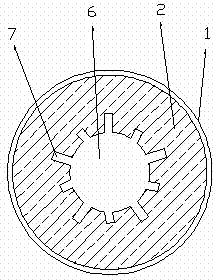

[0035] Embodiment 2: as Figure 5 For the hollow filter rod, the diameter 4 of the end surface of the filter rod is relatively small, the outer circumference is 16-19 mm, and the length is 60 mm. The filter element 2 has an axial hole and a plurality of radial holes 10 perpendicular to the axial direction, and the diameter of the radial holes 10 is smaller than that of the axial holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com