800 Mpa high-strength thick plate for high heat input welding

A high-energy-input welding and high-strength technology is applied in the field of structural steel to achieve excellent impact toughness and excellent comprehensive mechanical properties.

Active Publication Date: 2012-12-26

BAOSHAN IRON & STEEL CO LTD

View PDF8 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no 800MPa-level thick steel pla

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Average impact energy | aaaaa | aaaaa |

Login to View More

Abstract

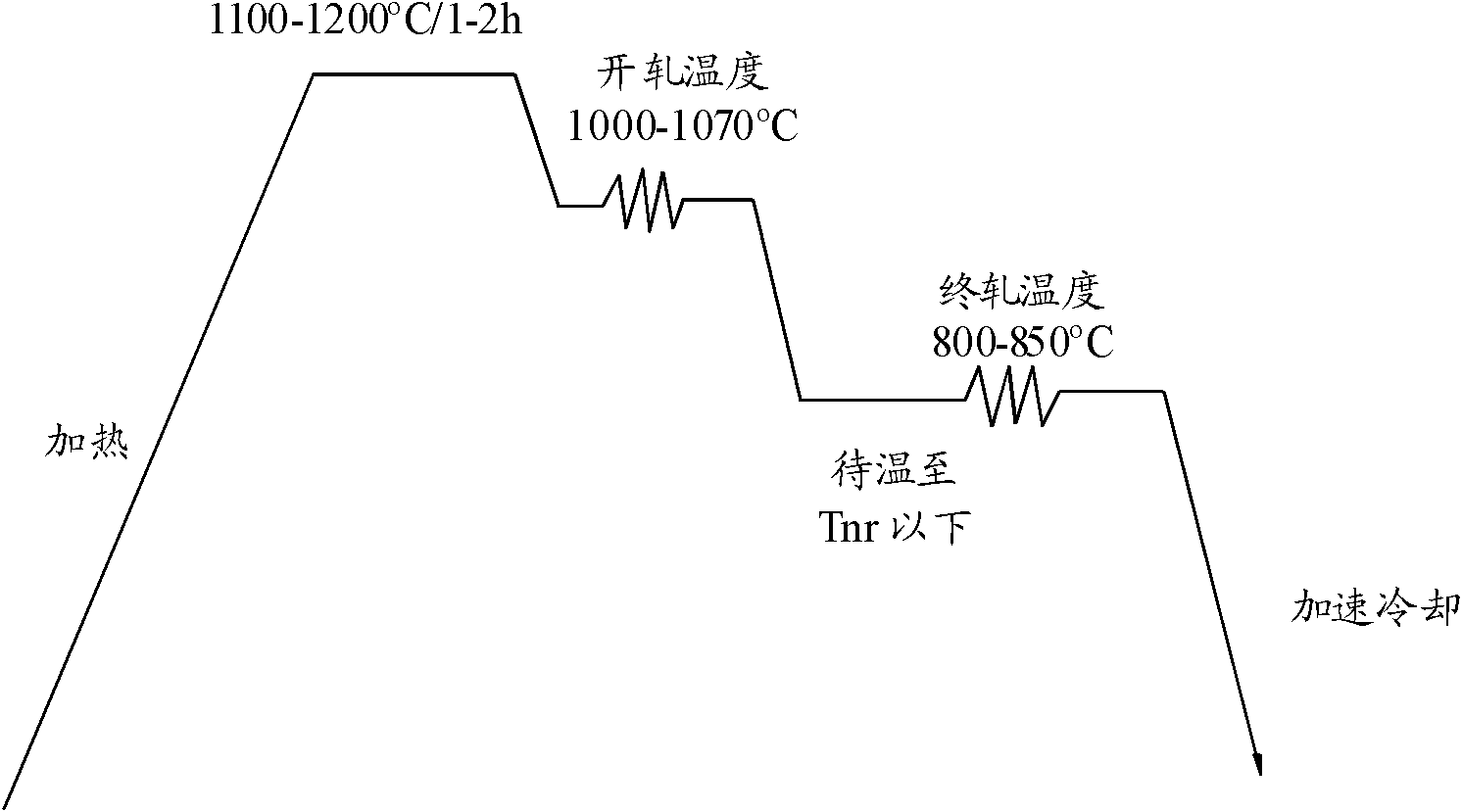

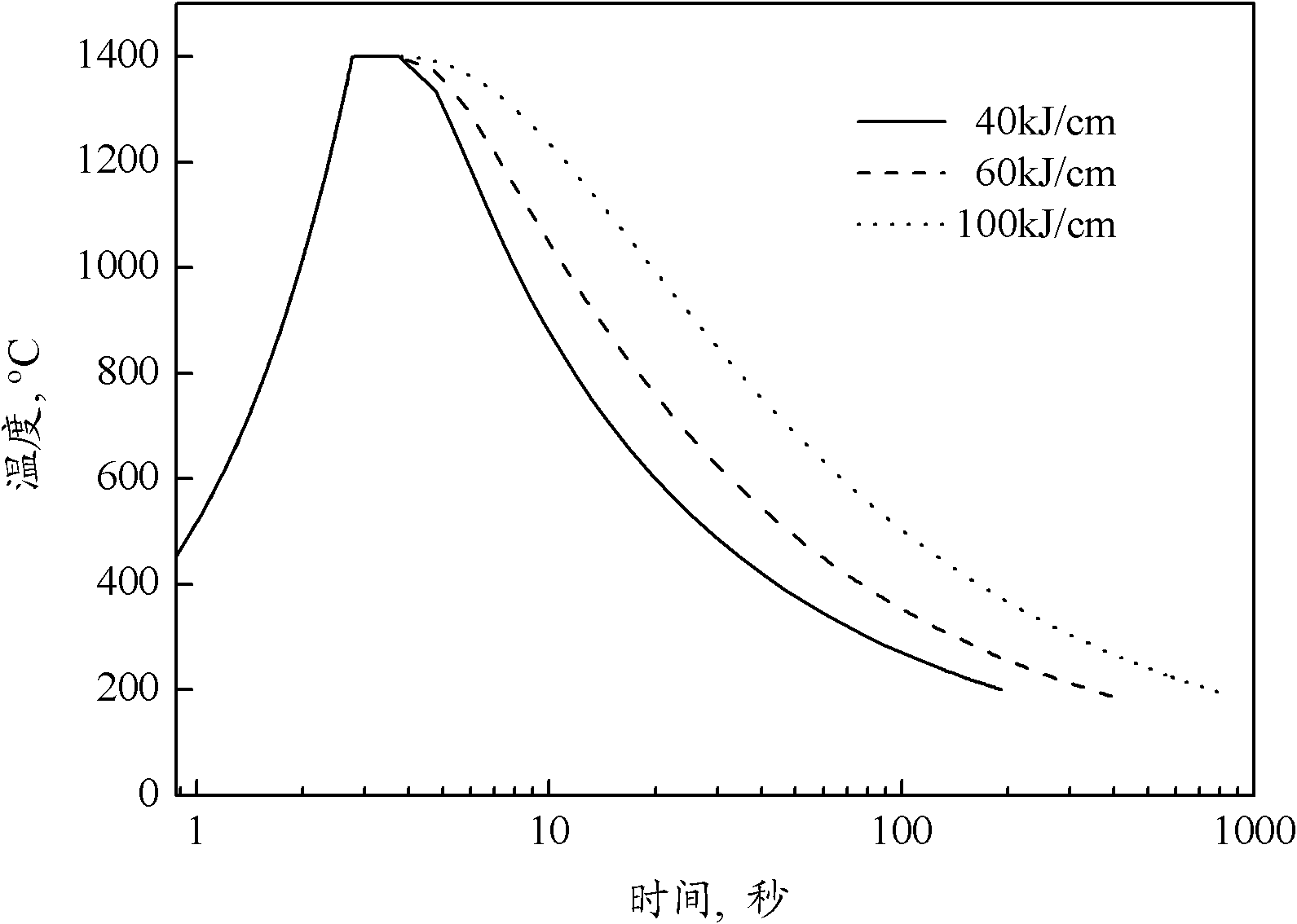

The invention relates to a high-strength steel plate for high heat input welding, which comprises the chemical compositions by weight percentage as follows: C (0.05-0.10%), Si (0.05-0.20%), Mn (0.5-1.5%), P (less than or equal to 0.015%), S (less than or equal to 0.005%), Al (0.02-0.08%), N (0.002-0.005%), Cr (0.1-0.5%), Mo (0.1-0.5%), Cu (0.2-0.5%), Ni (1.0-4.0%), O (less than or equal to 0.0030%), and the balance of Fe and other unavoidable impurities. The steel can be manufactured by the traditional thermal mechanical control process (TMCP) and the rapid cooling process. The yield strength of the steel is greater than or equal to 700 Mpa, the tensile strength of the steel is greater than or equal to 800 Mpa, the thickness of the steel is less than 30mm, and the high-strength high-ductility steel plate is suitable for 40-100kj/cm weld heat input; an HAZ (heat affected zone) of the steel plate is very good in impact ductility even at subzero 40 DEG C; and the steel plate has an excellent comprehensive mechanical property.

Description

technical field [0001] The invention relates to structural steel, in particular to a thick plate for 800MPa-level high-strength large-input energy welding and a manufacturing method thereof. Background technique [0002] Low-alloy high-strength steel is one of the most used structural materials and is widely used in oil and gas pipelines, shipbuilding, bridges, high-rise buildings, pressure vessels and other industries. In order to improve production efficiency, the above-mentioned industries have higher and higher requirements on the strength and weldability of structural steel plates, especially the high-energy-input weldability. However, high-energy-input welding is likely to cause a very serious problem, that is, welding around the weld The toughness of the heat-affected zone (HAZ) is severely deteriorated, and brittle fracture is extremely prone to occur. For traditional low-alloy steels, the welding input energy generally does not exceed 40kJ / cm. In this case, the det...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/44C21D8/02

Inventor 王巍王焕荣刘刚

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com