Bamboo flooring with cut surfaces in staggered flat compression and lateral compression and processing technology of bamboo flooring

A processing technology and cutting surface technology, which is applied in the field of staggered flat pressure side pressure cutting surface bamboo flooring and its processing technology, can solve the problems of single appearance, deformation, insufficient variety, etc., to improve added value, reduce deformation ability, Increase the viewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A staggered flat-pressed side-pressed cut surface bamboo floor and its processing technology include the following steps.

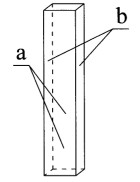

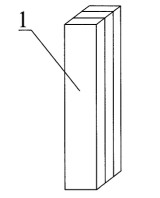

[0029] 1. Select bamboo slices, take the 2 faces with the largest area among the 6 sides of the bamboo slices as the front a, and the 2 sides with the second largest area as the side b; apply glue to the front a of each bamboo slice, and then Glue each other to form a germ strip 1.

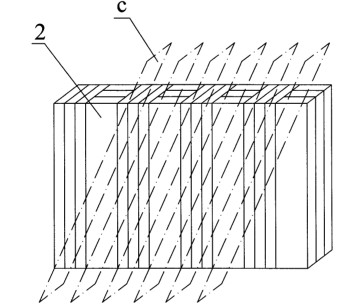

[0030] 2, the embryonic strip 1 is glued again, and then a side b of the bamboo sheet of the first embryonic strip 1 is cemented with a front a of the bamboo sheet of the second embryonic strip 1, and the second embryonic strip 1 is glued together. The other front side a of the bamboo slice of the 3rd germinal strip 1 is cemented with a side b of the bamboo slice of the 3rd germinal strip 1, and the other side b of the bamboo slice of the 3rd germinal strip 1 is bonded with the bamboo slice of the 4th germinal strip 1 A front side a phase of the bamboo is cemented, an...

Embodiment 2

[0035] A staggered flat-pressed side-pressed cut surface bamboo floor and its processing technology, characterized in that it comprises the following steps:

[0036] 1. Select bamboo slices, take the 2 faces with the largest area among the 6 sides of the bamboo slices as the front a, and the 2 sides with the second largest area as the side b; apply glue to the front a of each bamboo slice, and then Glue each other to form a germ strip 1.

[0037] 2, the embryonic strip 1 is glued again, and then a side b of the bamboo sheet of the first embryonic strip 1 is cemented with a front a of the bamboo sheet of the second embryonic strip 1, and the second embryonic strip 1 is glued together. The other front side a of the bamboo slice of the 3rd germinal strip 1 is cemented with a side b of the bamboo slice of the 3rd germinal strip 1, and the other side b of the bamboo slice of the 3rd germinal strip 1 is bonded with the bamboo slice of the 4th germinal strip 1 A front side a phase o...

Embodiment 3

[0043] A staggered flat-pressed side-pressed cut surface bamboo floor and its processing technology, characterized in that it comprises the following steps:

[0044] 1. Select bamboo slices, take the 2 faces with the largest area among the 6 sides of the bamboo slices as the front a, and the 2 sides with the second largest area as the side b; apply glue to the front a of each bamboo slice, and then Glue each other to form a germ strip 1.

[0045] 2, the embryonic strip 1 is glued again, and then a side b of the bamboo sheet of the first embryonic strip 1 is cemented with a front a of the bamboo sheet of the second embryonic strip 1, and the second embryonic strip 1 is glued together. The other side a of the bamboo sheet of the bamboo sheet is cemented with one side b of the bamboo sheet of the third root embryonic strip 1, and the other side b of the bamboo sheet of the third root embryonic strip 1 is bonded with the bamboo sheet of the fourth embryonic strip 1 A front side a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com