Method for molding headrest of vehicle

A molding method and technology for car seats, which are applied in the field of molding car seat headrests, can solve the problems of enlarged triangle area, difficulty in fitting fabrics, and reduced product value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

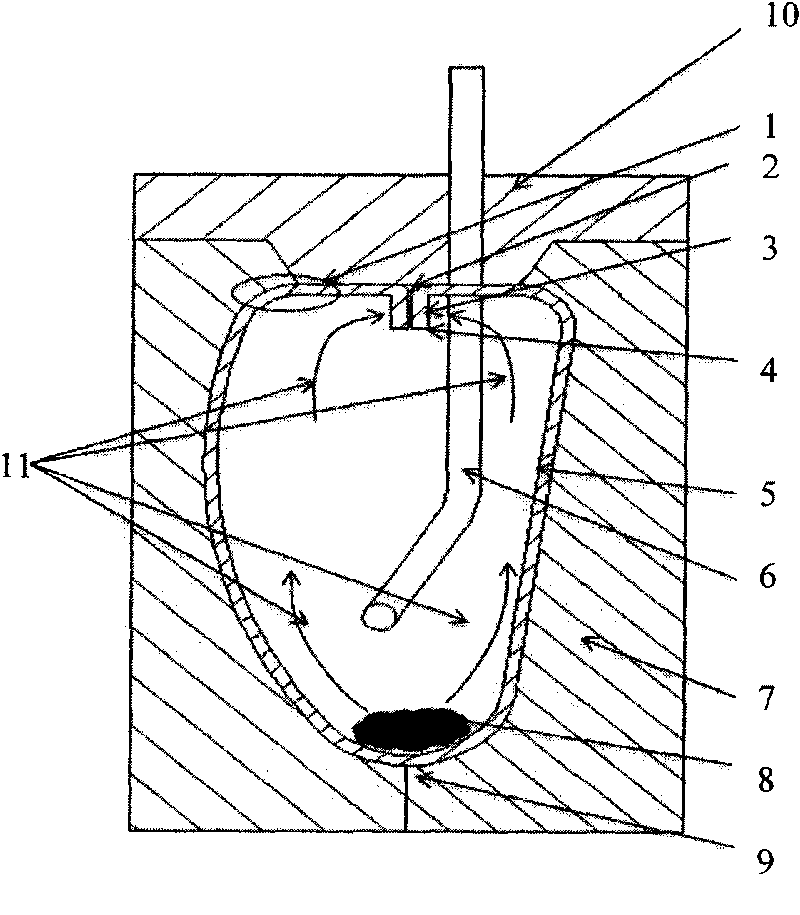

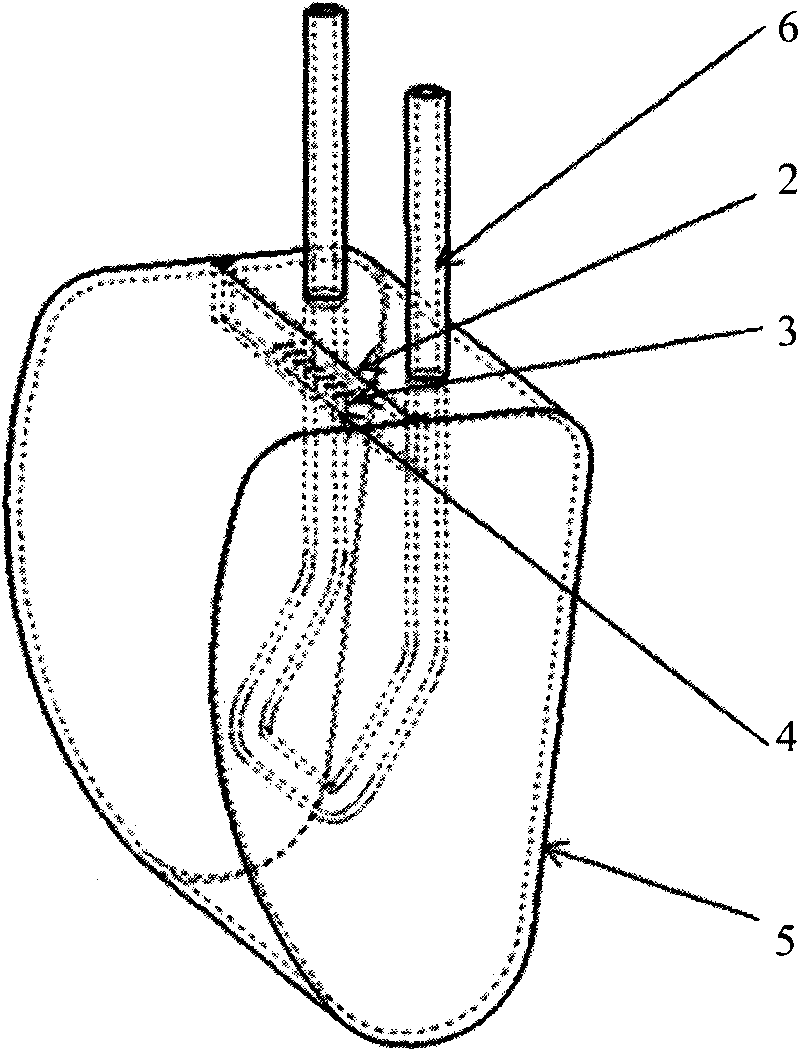

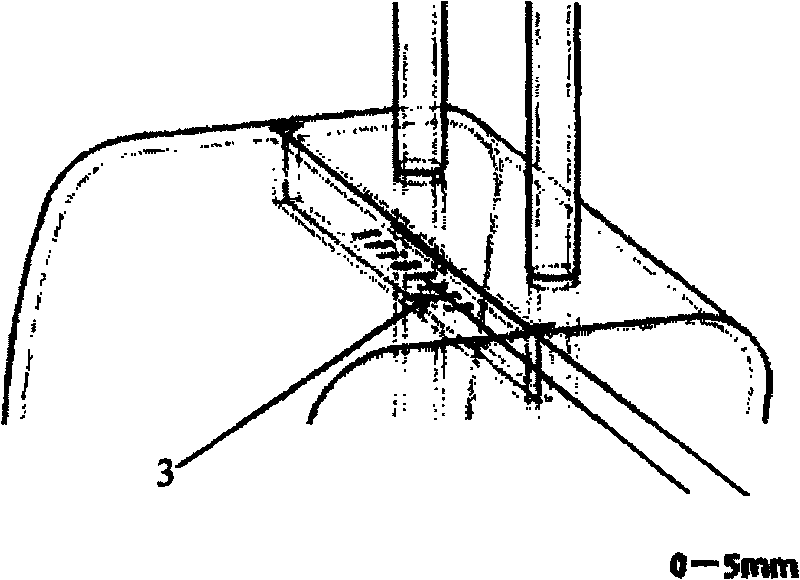

[0023] The characteristics and advantages of the method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] In order to solve the contradiction between the height of the air outlet point and the overflow of raw materials, the present invention provides a new PIP foam molding method for automobile seat headrests, which can greatly increase the resistance of the air outlet point of the cover to the overflow of chemical materials, and maximize the Shorten the distance between the air outlet point and the opening 2 of the mask. While better reducing the triangular area where the gas cannot be discharged, the possibility of raw materials seeping out from the gas outlet point is avoided.

[0025] According to one aspect of the present invention, when the face cover opening 2 of the headrest is at the highest point of the headrest product, or by adjusting the angle of the product, the opening 2 ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com