Underwater no-bottom closing concrete boxed cofferdam and method of use thereof

A technology of back-sealing concrete and its application method, which is applied in the direction of construction and infrastructure engineering, etc., can solve the problems such as difficult control of the construction quality of caps, elevation of the bottom of caps, and large amount of water work, so as to reduce the amount of water work and quality Control, quality and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

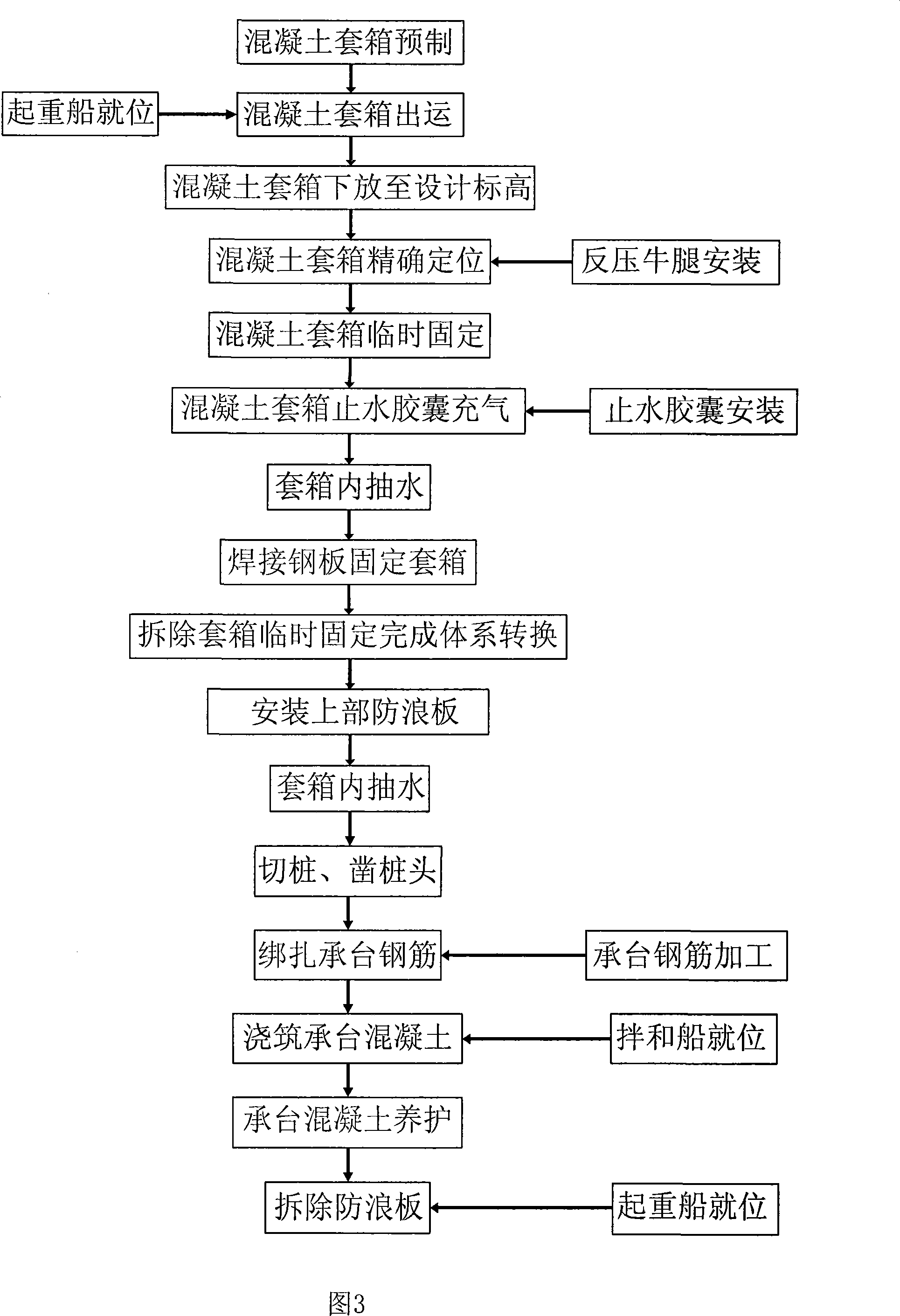

Method used

Image

Examples

Embodiment Construction

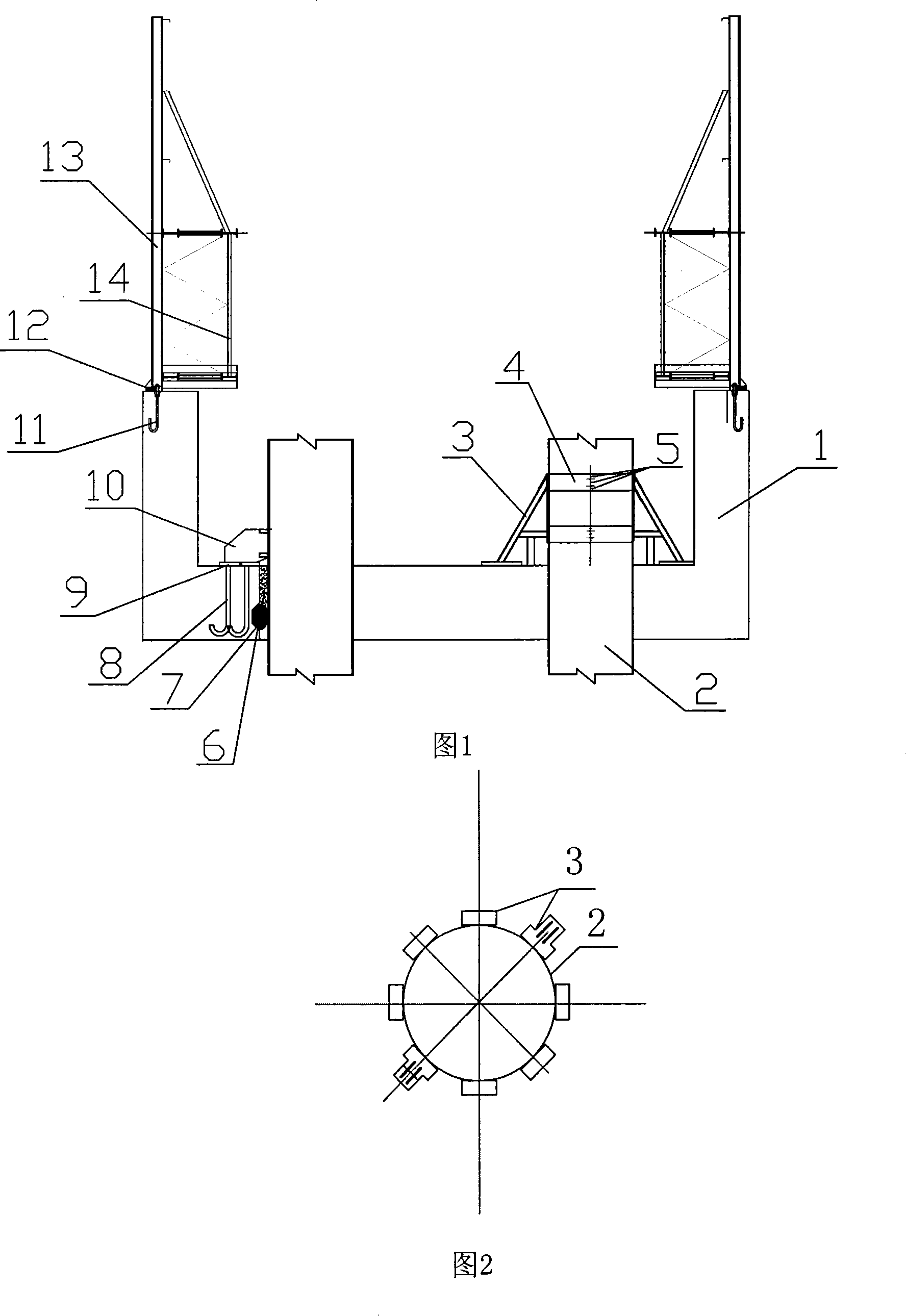

[0019] main structure design

[0020] As shown in Figure 1, the technical structure of this scheme is divided into two parts: permanent structure and temporary structure. Among them, the permanent structure part includes: concrete casing 1, anchor steel plate 9, water-stop capsule 7, etc.;

[0021] Concrete box 1 (reinforced concrete box) structure design and installation instructions:

[0022] The upper part of the columnar box is open, the bottom is provided with a box bottom, and the cylindrical box wall is closed; there is a gap between the inner wall of the box and the outer surface of the cap, and the height of the box is consistent with the size of the cap; the bottom of the box is reserved The number of holes is the same as the number of bored piles at the same pier position; pre-embedded bolts 11 used to connect the anti-wave plate are embedded on the top of the box wall, and water-stop airbag reserved grooves are set around the reserved holes at the bottom of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com