Gravity type offshore wind turbine generator set foundation and towing and sinking method thereof

A kind of offshore wind power and basic technology, applied in the direction of basic structure engineering, construction, etc., can solve problems such as hidden dangers of buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

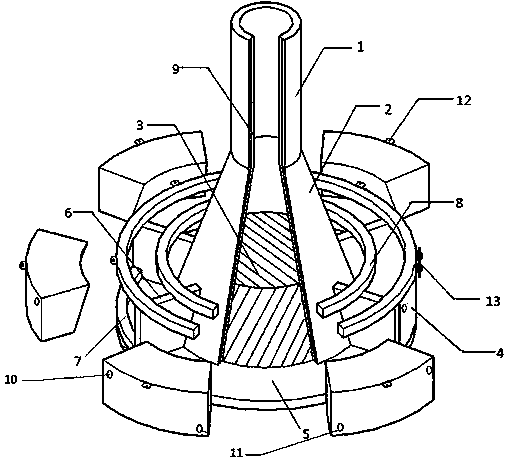

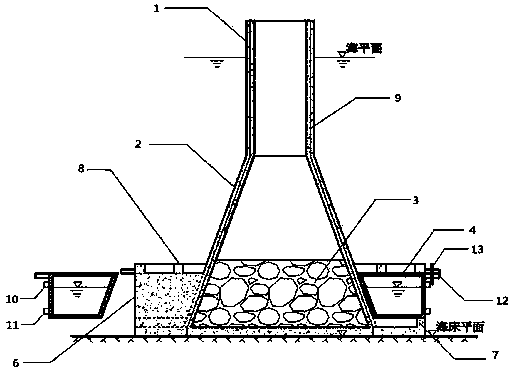

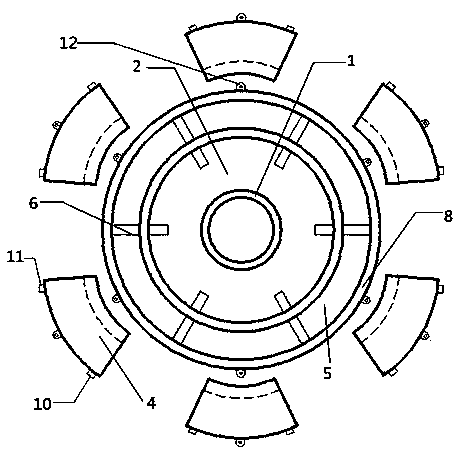

[0023] A towable gravity offshore wind turbine foundation, such as Figure 1-3 As shown, it is composed of connecting section 1, foundation main body 2, sand and gravel loading 3 and buoyancy tank 4. The connecting section 1 is a reinforced concrete cylinder; the foundation main body 2 is located below the water level and consists of a foundation base and a reinforced concrete cone. The base is a concrete member, including a bottom plate 5 and ribs 6. The outer edge of the circular bottom plate is provided with a bottom plate ring beam 7. The circular bottom plate 5 is fixed to the rock foundation through grouting. The ribs 6 are radially and evenly distributed around the reinforced concrete cone. , the number of ribs 6 is 6, the top of the ribs 6 is provided with 2 rib ring beams 8, the bottom of the ribs 6 is integrated with the bottom plate 5, the inner side of the ribs 6 is connected with the outer wall of the reinforced concrete cone Integrate into one body, the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com