Line shape control method for short line method segment prefabrication construction

A technology of linear control and short-line method, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problem that the accuracy of bridge linear control cannot meet the requirements, limit the development of short-line method segmental prefabrication construction methods, and affect the progress of bridge engineering construction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

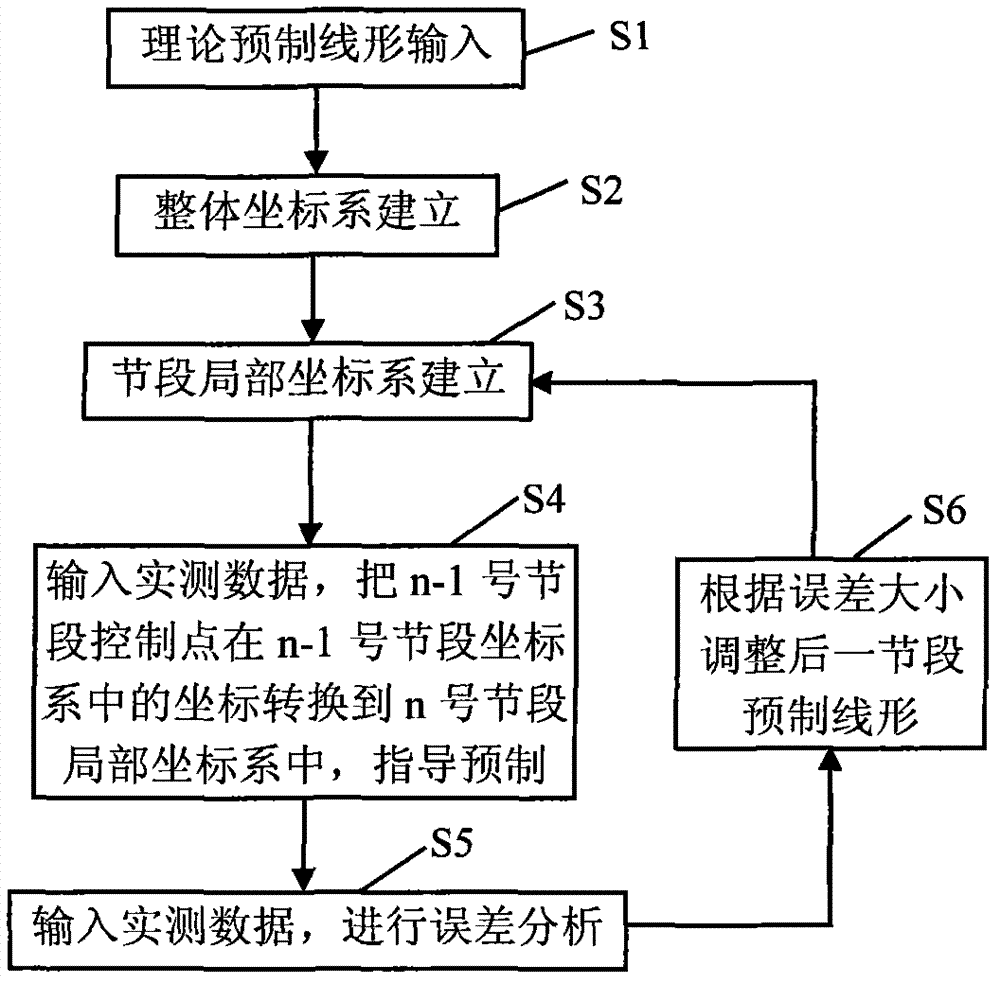

[0048] see figure 1 As shown, the embodiment of the present invention provides a method for controlling the alignment of segmental prefabrication construction by short-line method, which includes the following steps:

[0049] S1. According to the design alignment and construction sequence of the bridge, calculate the theoretical prefabricated alignment according to the tangent displacement method.

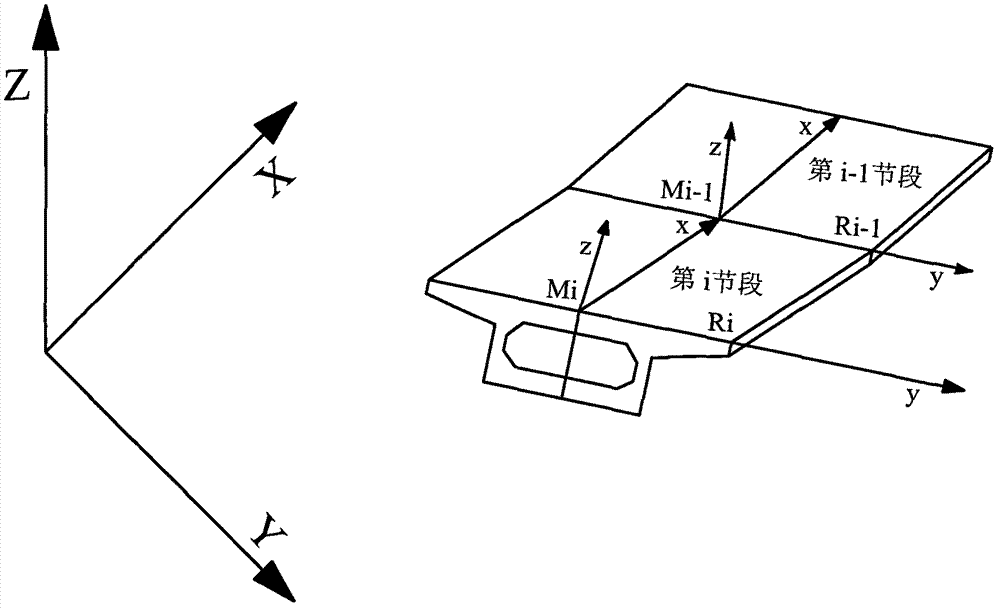

[0050] S2. To establish the prefabricated linear overall seating system, the geodetic coordinate system of bridge design can be directly adopted as the prefabricated linear overall seating system.

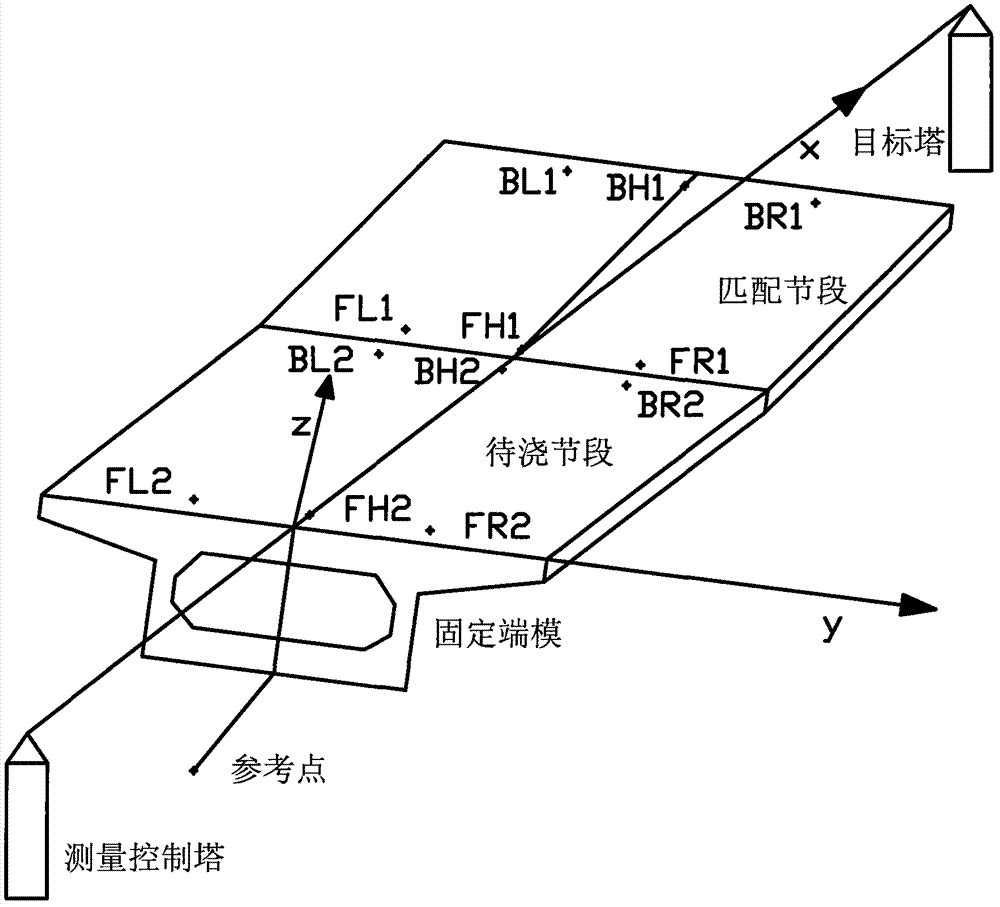

[0051] S3. Establishing the local coordinate system of each prefabricated segment. The segmental local coordinate system is established at the center of the segmental top plate on the side of the fixed end mold during segmental prefabrication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com