Prefabricated bathroom assembly and methods of its manufacture and installation

a technology of prefabricated bathroom and bathroom body, which is applied in the field of prefabricated bathroom body, can solve the problems of high labor cost, excessive delay, and slow turnaround time of such bathroom construction, and achieve the effect of maximum aesthetic quality and comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

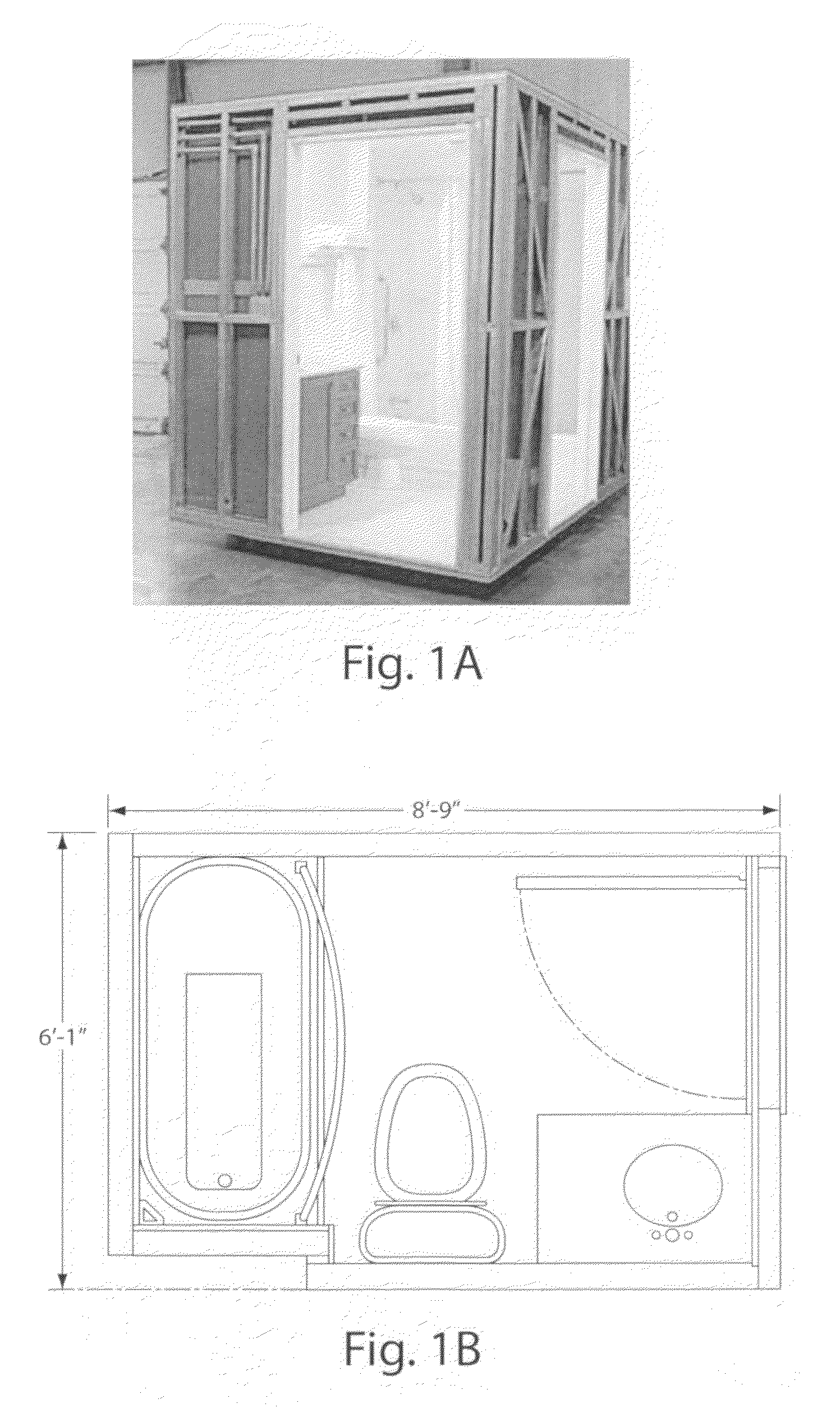

[0041]FIG. 1A shows a prefabricated bathroom assembly in accordance with an embodiment of the present invention. The prefabricated bathroom assembly may built in compliance with the floor plan shown in FIG. 1B and / or additional instructions such as information or customer preferences regarding the positioning of electrical connections and plumbing, design specifications (e.g., choices of fixtures and / or tiles), and any other suitable instructions. The prefabricated bathroom assembly may be framed with steel studs and finished with materials traditionally used in the on-site construction of residential bathrooms (e.g., ceramic tiles, vanities, wall paper, paint, etc.). Additionally, the prefabricated residential bathroom assembly may include all plumbing and electrical components necessary for hook up to utilities at the construction site, and may require only fastening into place and connection to the utilities at the site in order to complete the installation. Such a sturdy constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com