Bake-free iron runner ramming mass containing ferrosilicon nitride

A technology of ferrosilicon nitride and ramming material, applied in the direction of discharge devices, etc., can solve the problems of reduced corrosion resistance, low temperature, high impurities, etc., and achieve the effect of increasing oxidation resistance and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

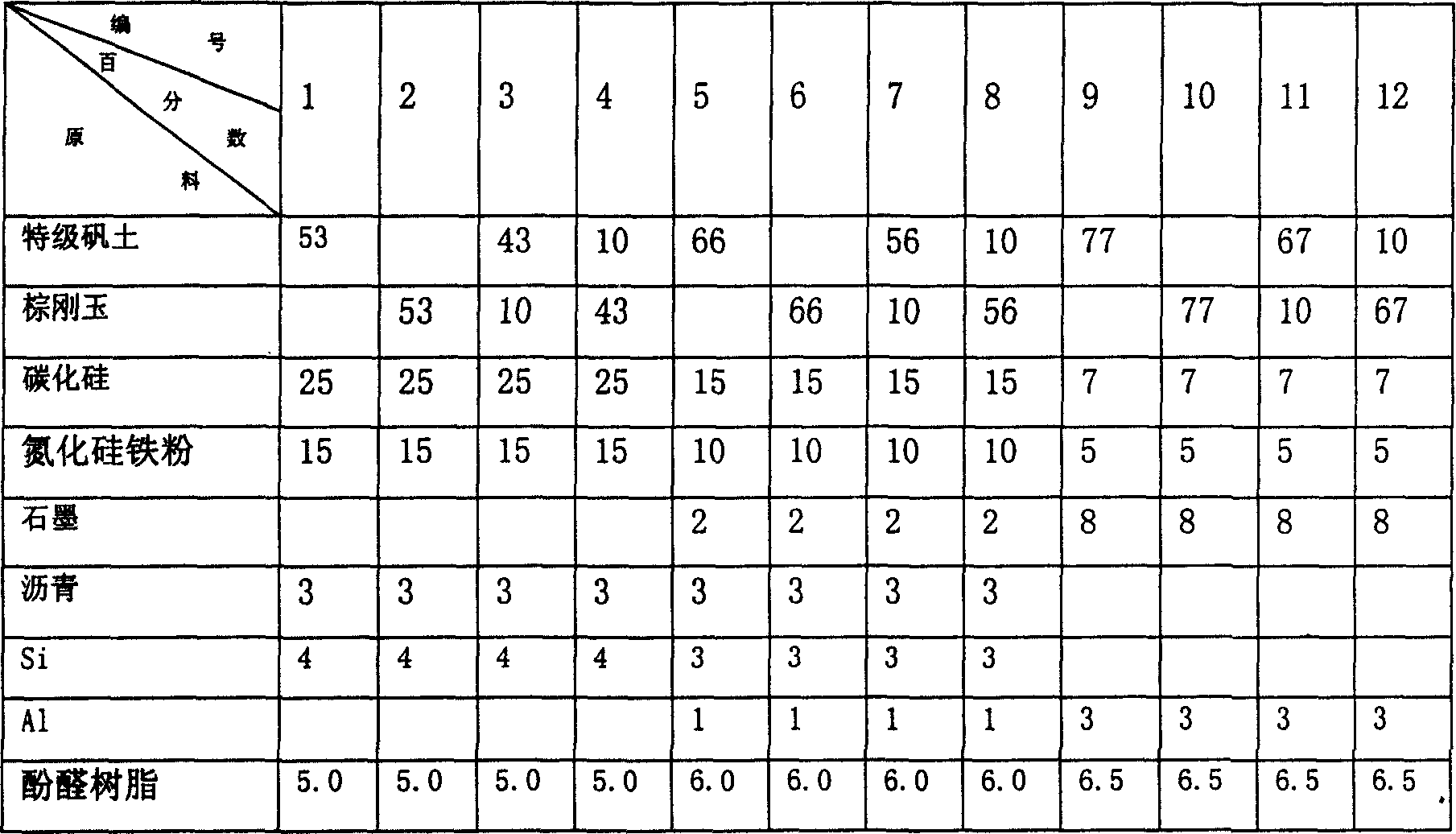

[0035] Add super bauxite, brown corundum, silicon carbide, graphite, pitch, ferrosilicon nitride, metal Al, Si, etc. into the mud mill in proportion, after a little mixing, add phenolic resin and stir until it is evenly mixed. 12 specific implementations of the present invention benefit batching ratio table:

[0036] Table embodiment proportioning (percentages in the table are mass percentages)

[0037]

[0038] The sum of the proportions of super-grade alumina, brown corundum, silicon carbide, silicon nitride iron powder, graphite, pitch, Si, and Al in the ingredient list is 100%, while the addition of phenolic resin is 5.0% and 6.0% of the total raw materials , 6.5%.

[0039] Due to the addition of ferrosilicon nitride, the performance of the iron trench ramming material is greatly improved. According to the ramming material that No. 6 scheme is made in the list of examples at 450m 3 It can be used on the blast furnace iron trench for more than 15 days, which is 4-5 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com