Automatic nine-station casting machine for engine cylinder liner blank

An engine cylinder, automatic pouring technology, applied in the direction of manufacturing tools, metal processing equipment, equipment for feeding molten metal into casting molds, etc., can solve the problems of high labor intensity, low work efficiency, low production efficiency, etc. The effect of employee labor intensity, improving production efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

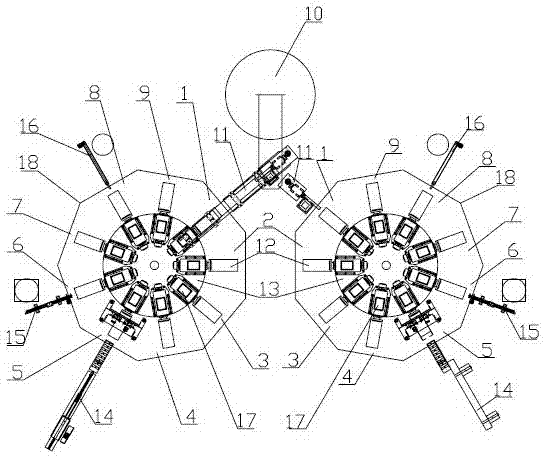

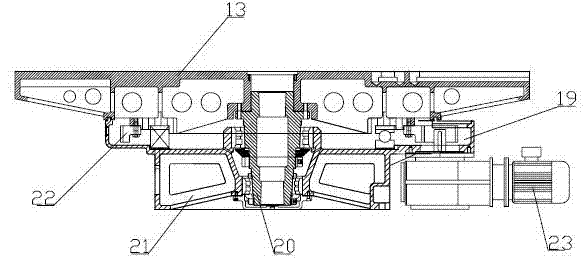

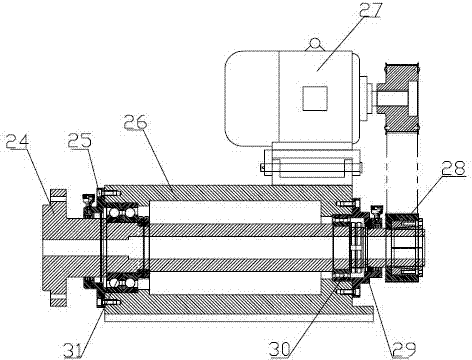

[0032] Such as figure 1 As shown, the nine-station engine cylinder liner blank automatic pouring machine includes a nine-station rotary table 13 connected to the power unit, on which nine casting power heads 17 and centrifugal casting molds 12 are loaded, (such as figure 2 As shown), the rotary table 13 is installed on the machine base 21, the rotary table 13 is connected with the main shaft 20, and the large gear 22 is installed on the main shaft 20, the large gear 22 is connected with the pinion 19, and the small gear 19 is connected with the reduction Motor 23 transmissions are connected, and reduction motor 23 drives workbench to rotate through pinion 19 and bull gear 22; (as image 3 As shown) the casting power head 17 includes a box body 26 on which a motor 27 is arranged. The motor 27 is connected to the power shaft 24 through a pulley 28. The power shaft 24 passes through the box body 26 and is arranged at both ends of the box body 26 The bearings 30, 31 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com