High-concentration dilution system and method for zero-wine-loss beer

A technology of beer and diluter, which is applied in the preparation of alcoholic beverages, etc., which can solve the problems of unable to discharge the fermentation liquid, wine damage, and high production cost, and achieve the effects of stable flow rate, elimination of wine tail, and reduction of wine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

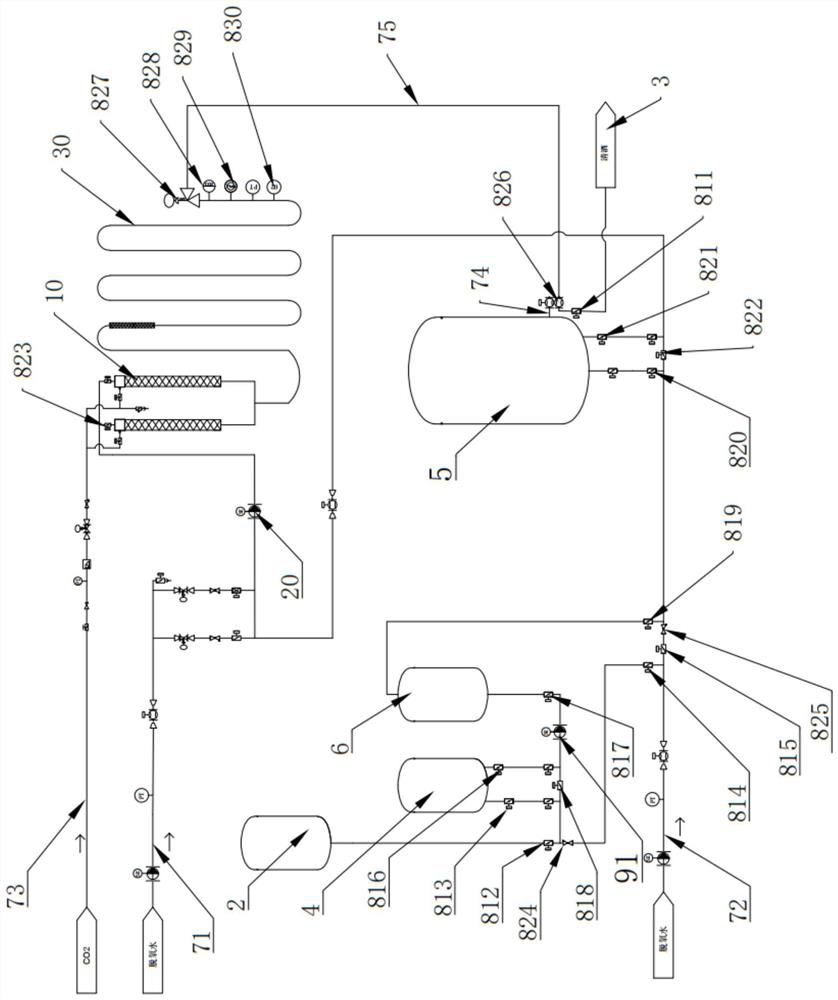

[0038] A high-concentration dilution system for zero-loss beer, such as figure 1 As shown, it is set between the fermenter tank 2 and the sake tank 3. The zero-loss beer high-concentration dilution system includes a front buffer tank 4, a filter 6, a rear buffer tank 5, and a dilution machine 1 connected in sequence through pipelines. The liquid outlet of tank 2 is communicated with the liquid inlet of front buffer tank 4, and the liquid outlet of back buffer tank 5 is communicated with the liquid inlet of diluter 1, and the liquid outlet of diluter 1 is connected with sake through wine outlet pipeline 75. Tank 3 is connected. Wherein, the function of the front buffer tank 4 is to prevent the high-strength beer in the fermenter 2 from directly entering the filter 6 from impact damage to the filter element in the filter 6, and a front buffer tank is arranged between the fermenter 2 and the filter 6 4. Pressure buffer the high-pressure high-concentration beer in the pipeline. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com