Ejection ball system and conveying system

A technology of ejecting material and input end, which is applied in the field of ejecting ball system and transmission system, can solve the problem of liquid residue in the pipeline, and achieve the effect of reducing dosage, saving wine loss, and reducing CIP time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

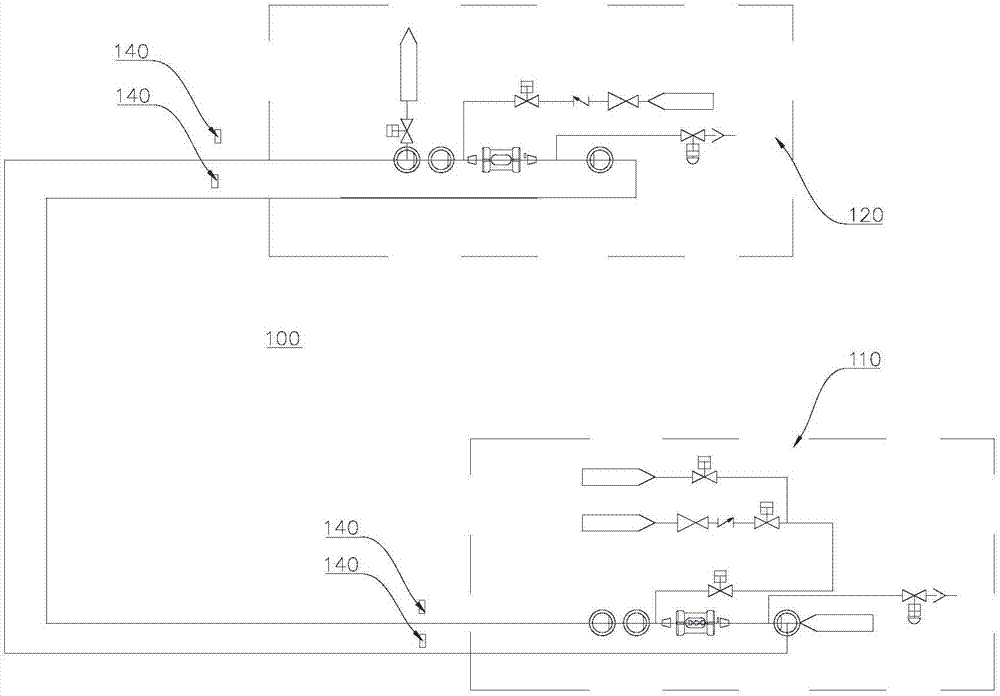

[0031] Please refer to Figure 1 to Figure 4 , the present embodiment provides a ball ejecting system 100 , which includes a launching station 110 , a recycling station 120 , a controller 130 , a position sensor 140 and a display screen 150 .

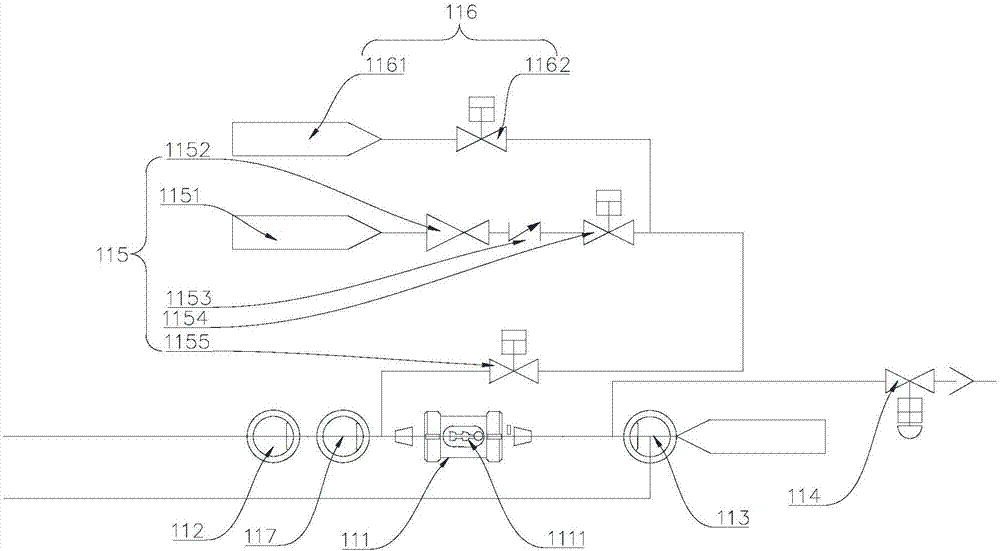

[0032]The launch station 110 includes a first observation window 111 , a first valve 112 , a second valve 113 , a first outlet valve 114 and a first carbon dioxide feeder 115 .

[0033] In this embodiment, the input end of the first observation window 111 is connected to the output end of the first valve 112 , and the output end of the first observation window 111 is connected to the input end of the second valve 113 . Wherein, the first observation window 111 may be connected to the first valve 112 and the second valve 113 through connecting pipes.

[0034] A ejector ball 1111 is arranged in the first observation window 111 .

[0035] In this embodiment, the ejector ball 1111 is used to enter the recovery station 120 under the push o...

no. 2 example

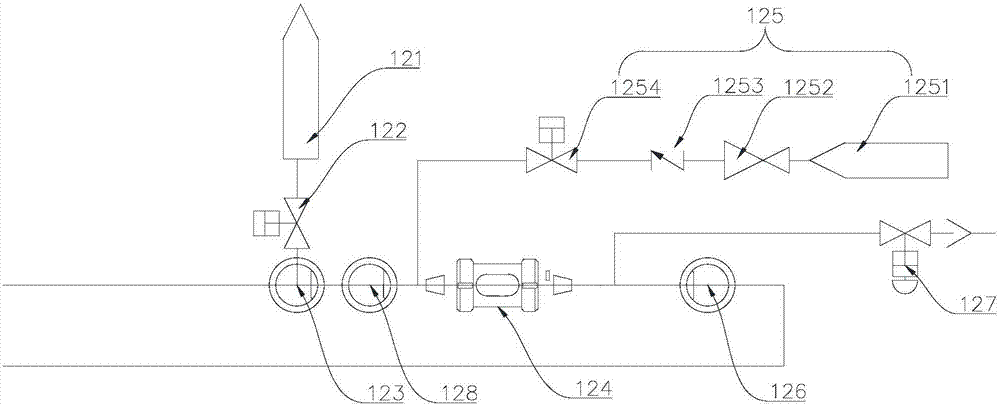

[0074] Please refer to Figure 5 , the present embodiment provides a conveying system 200 , which includes a conveying pipe 210 and an ejector ball system 100 .

[0075] The conveying pipe 210 is connected with the ejector ball system 100 .

[0076] In this embodiment, there are multiple delivery pipes 210 . Preferably, there are two delivery pipes 210 . One of the delivery pipes 210 communicates with the first discharge valve 114 . The other one communicates with the second discharge valve 127 .

[0077] In this embodiment, the delivery pipe 210 is used to deliver the liquid passing through the first discharge valve 114 and the second discharge valve 127 to a predetermined position.

[0078] In summary, the present invention provides a ball ejecting system 100 and a transmission system 200. By setting the ejecting balls 1111 in the first observation window 111, the ejecting balls 1111 can transfer the ejecting balls in the ejecting ball system 100 to Connect the wine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com