Isobaric filling and sealing device compatible with containers of different specifications

A sealing device and filling technology, applied in the direction of using back pressure infusion, packaging, bottle filling, etc., can solve the problems of foam, inconsistent specifications, beer waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing and embodiment:

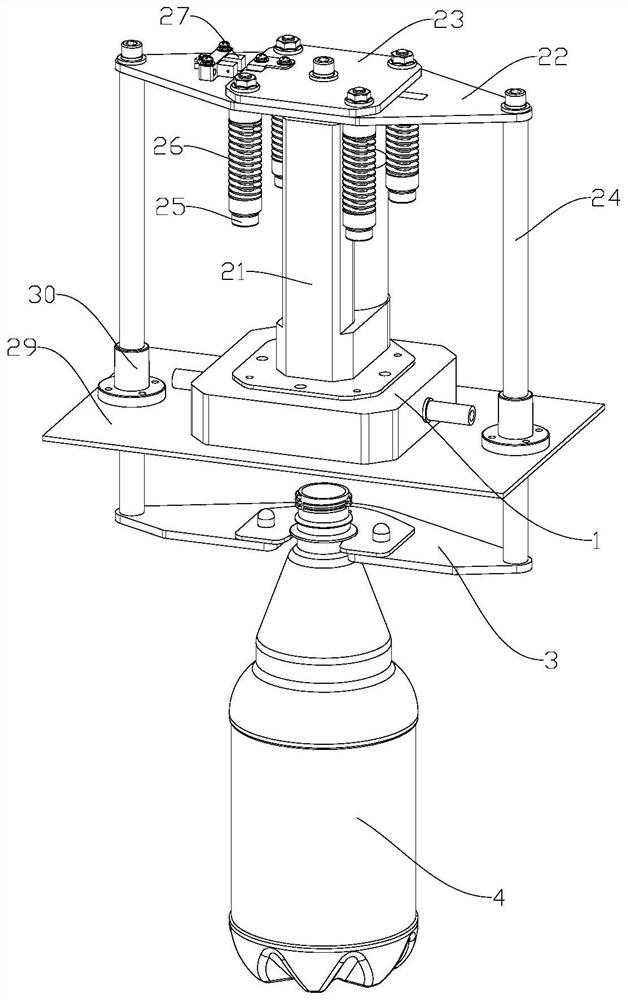

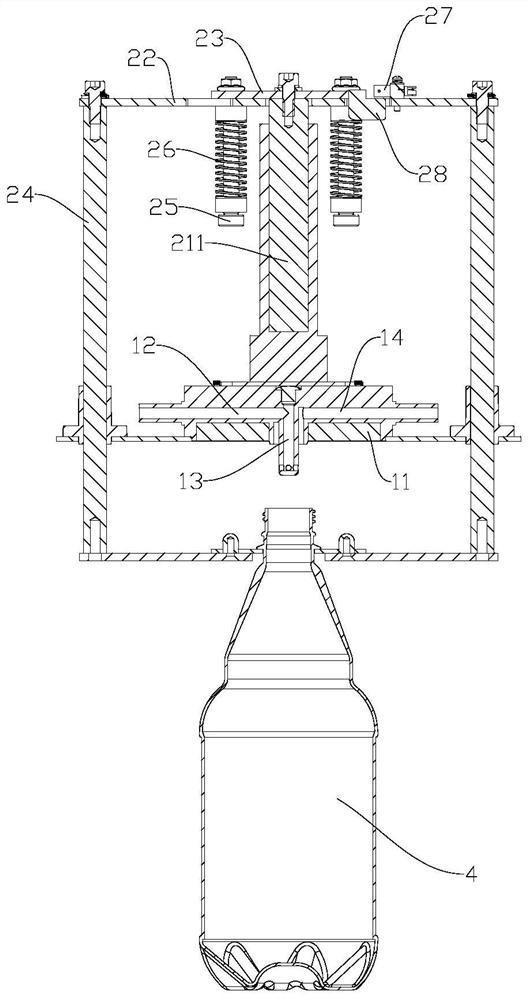

[0034] Such as Figure 1 to Figure 3 As shown, an isobaric filling and sealing device compatible with containers of different specifications, including a filling seat 1, a lifting assembly 2 fixed on the filling seat 1, a moving assembly 3 arranged under the filling seat 1, and 4 containers On or set on the mobile assembly 3.

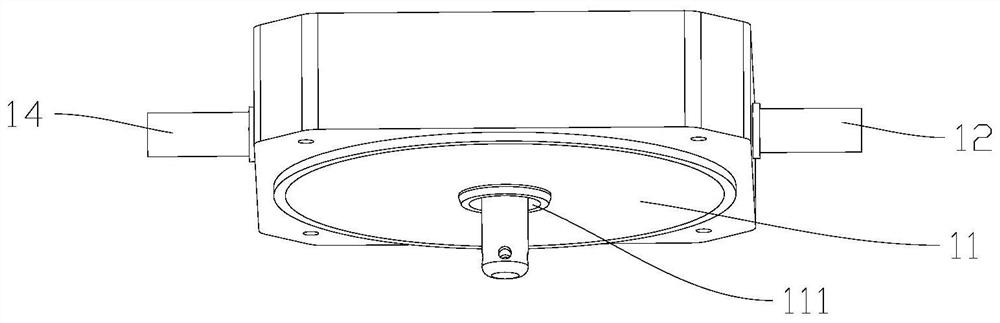

[0035] The filling seat 1 includes a silica gel gasket 11, an air inlet and an exhaust wine outlet 14, the silica gel gasket 11 is embedded in the bottom of the filling seat 1, and a through hole 111 for accommodating the air inlet and wine inlet is provided in the middle , The through hole 111 communicates with the exhaust and wine outlet 14.

[0036] Preferably, the caliber of the through hole 111 is smaller than the caliber of the container 4. When the bottle mouth of the container 4 is pushed against the silicone gasket 11, the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com