Advanced substrate glass melting device and method

A melting device and substrate technology, applied in glass furnace equipment, glass manufacturing equipment, electric furnace, etc., can solve the problems of slag, uneven combustion of upper and lower raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

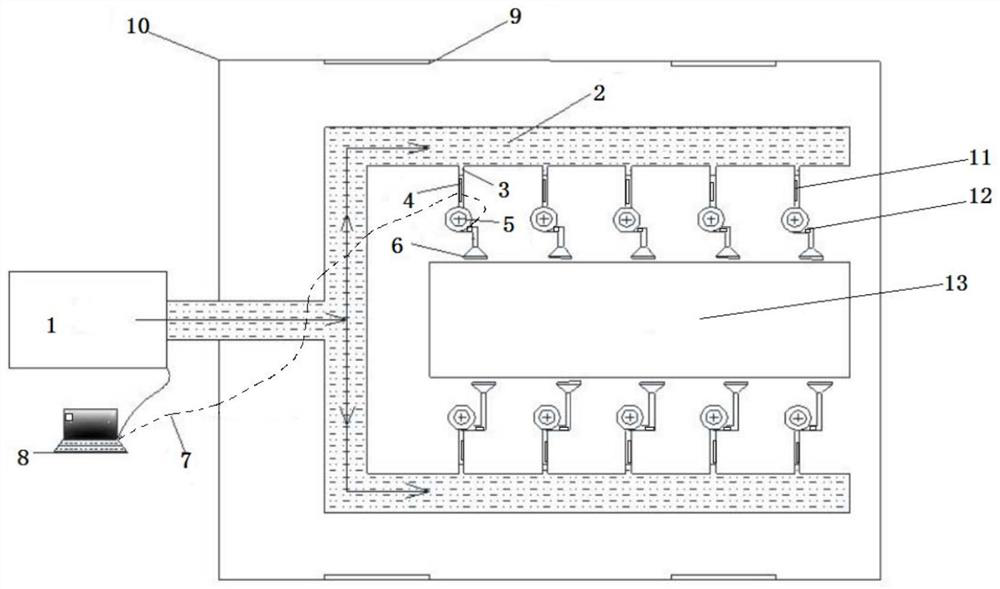

[0034] In order to solve the problem of kiln temperature fluctuation and furnace pressure fluctuation caused by ambient wind to the kiln pool wall, the present invention designs an air-conditioning constant temperature monitoring system, such as figure 1As shown, in this structure, an air-conditioning constant temperature detection system is set on the outside of the kiln furnace 13, that is, the air-conditioning constant temperature detection system includes an air-conditioning unit 1, an air supply duct 2, an air-conditioning outlet 3, an air-conditioning hose 4, a centrifugal fan 5, and a duckbill air duct 6. Signal line 7, signal monitoring system 8, air return port 9 and kiln enclosure wall 10; The surrounding wall 10 of the kiln furnace is connected to the air conditioning unit 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com