Ultrasonic liquid level measuring method and ultrasonic liquid level measuring device

A liquid level measurement, ultrasonic technology, applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc., can solve the problems of increased manufacturing cost and difficult construction, etc., to achieve increased manufacturing cost, convenient and simple realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

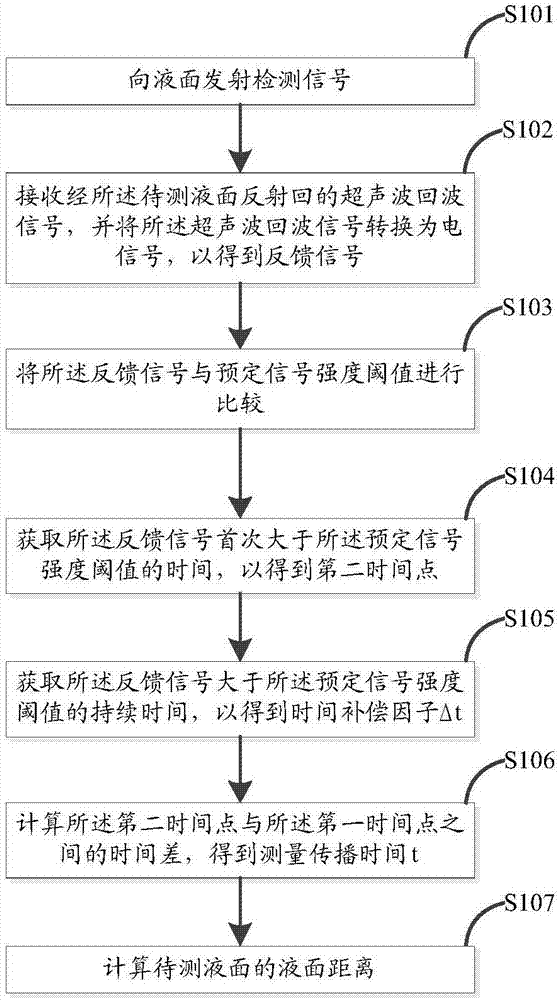

[0048] Embodiment 1 of the present application is a method of ultrasonic measurement of liquid level, see figure 1 , the method includes:

[0049] Step S101, transmitting a detection signal to the liquid surface, wherein the detection signal is an ultrasonic signal, and the time of transmitting the detection signal is the first time point;

[0050] Step S102, receiving the ultrasonic echo signal reflected by the liquid surface to be tested, and converting the ultrasonic echo signal into an electrical signal to obtain a feedback signal, wherein the feedback signal is an oscillation signal;

[0051] Step S103, comparing the feedback signal with a predetermined signal strength threshold;

[0052] Step S104, obtaining the time when the feedback signal is greater than the predetermined signal strength threshold for the first time, so as to obtain a second time point;

[0053] Step S105, obtaining the duration time during which the feedback signal is greater than the predetermined s...

Embodiment 2

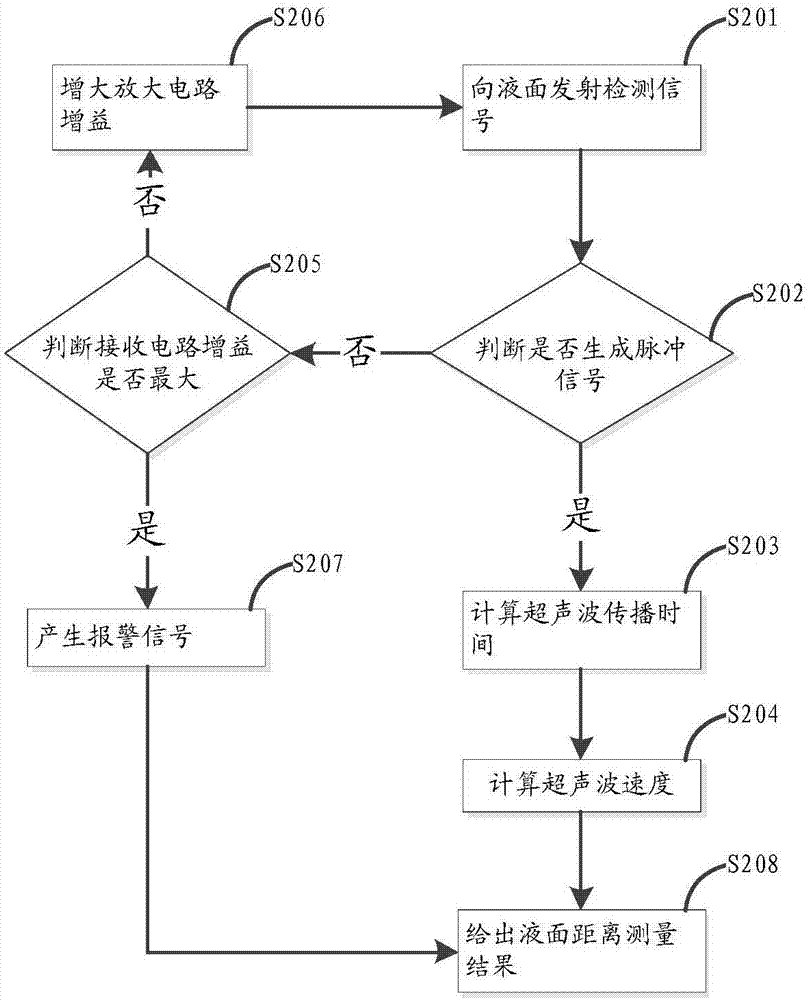

[0058] A method for measuring liquid surface distance with ultrasonic waves, its flow chart can be found in figure 2 , the method includes:

[0059] Step S201, sending a detection signal to the liquid surface;

[0060] Step S202, judging whether to generate a pulse signal;

[0061] Step S203, calculating the ultrasonic propagation time;

[0062] Step S204, calculating the ultrasonic velocity;

[0063] Step S205, judging whether the gain of the receiving circuit is maximum;

[0064] Step S206, increasing the gain of the receiving circuit;

[0065] Step S207, generating an alarm signal;

[0066] Step S208, giving the liquid surface distance measurement result;

[0067] In the above step S201, a detection signal is transmitted to the liquid surface, wherein the detection signal is an ultrasonic wave, and the time of transmitting the detection signal is the first time point, and then go to step S202.

[0068] In the above step S202, starting from the first time point in th...

Embodiment 3

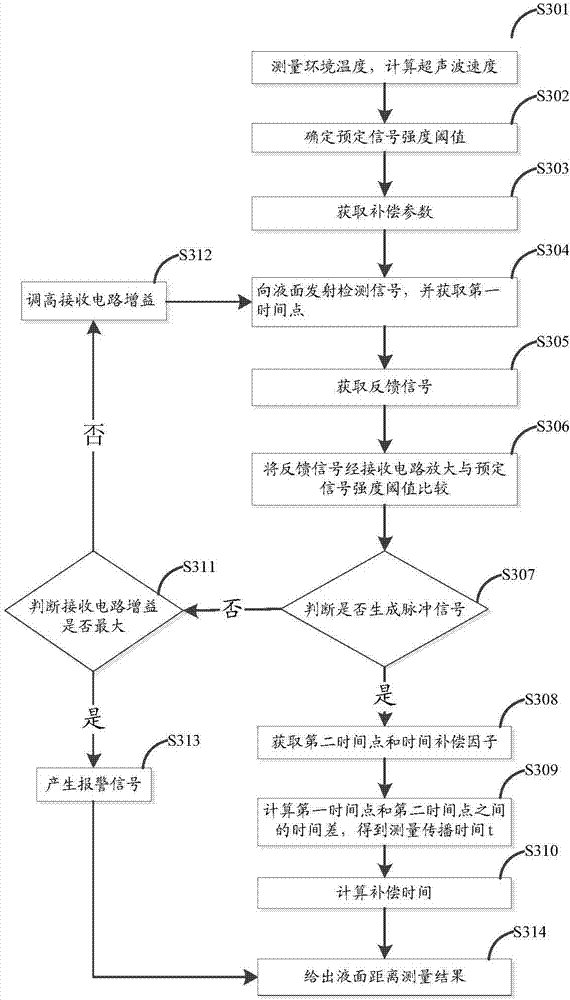

[0097] Embodiment 3 of the present application is a more preferred ultrasonic liquid level measurement method, the flow chart of which can be found in image 3 , the method includes:

[0098] Step S301, measuring the ambient temperature and calculating the ultrasonic velocity, where the ambient temperature value T is measured, then the propagation velocity v of the ultrasonic wave in the air at the current ambient temperature is:

[0099]

[0100] where, where, v 0 Indicates the propagation speed of the ultrasonic signal in the air at 0°C;

[0101] Step S302, determining a predetermined signal strength threshold, wherein the value range of the predetermined signal strength threshold is 50% to 75% of the maximum amplitude corresponding to the minimum range of the ultrasonic liquid level gauge, and the maximum amplitude corresponding to the minimum range of the ultrasonic liquid level gauge is When the amplitude is equal to the liquid level distance of the predetermined liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com