Non-contact type single-point liquid metal liquid level measurement device

A liquid level measuring device, liquid metal technology, applied in the direction of measuring device, testing/calibration device, liquid/fluid solid measurement, etc. It is difficult to guarantee and affect the accuracy and reliability of the liquid level signal, so as to achieve the effect of improving the liquid level measurement accuracy and use range, increasing the use range and reducing limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

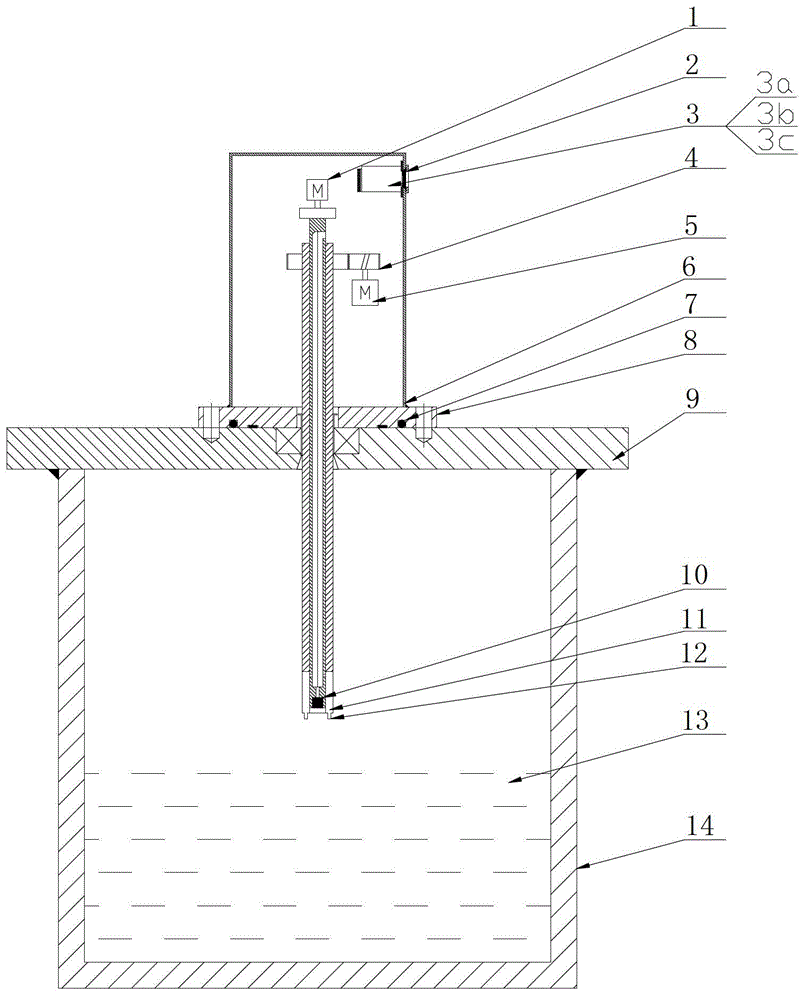

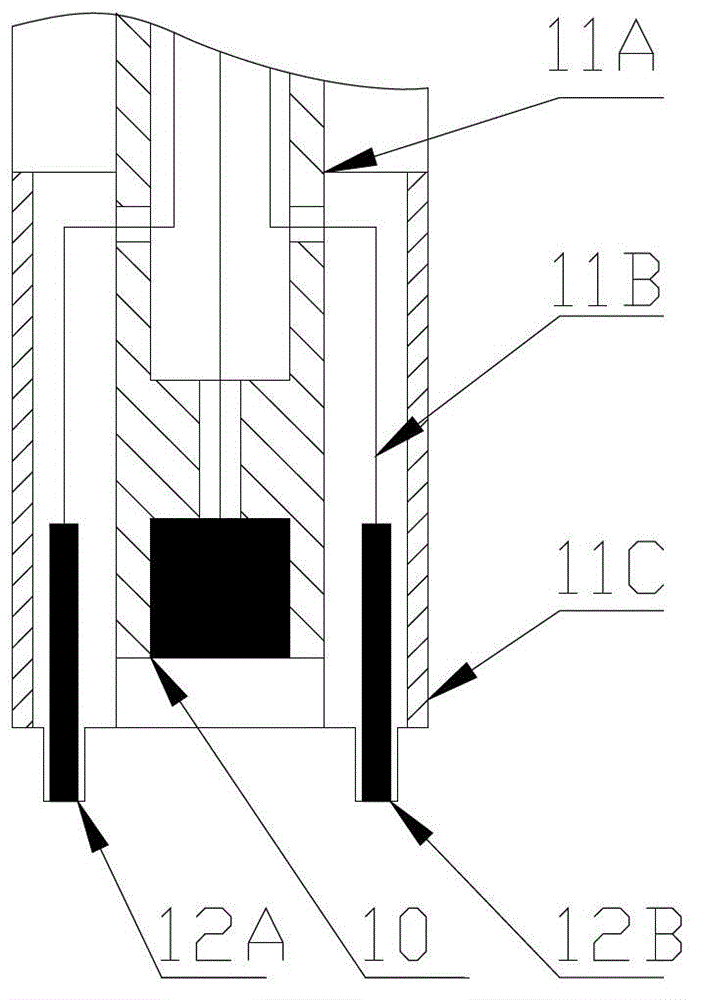

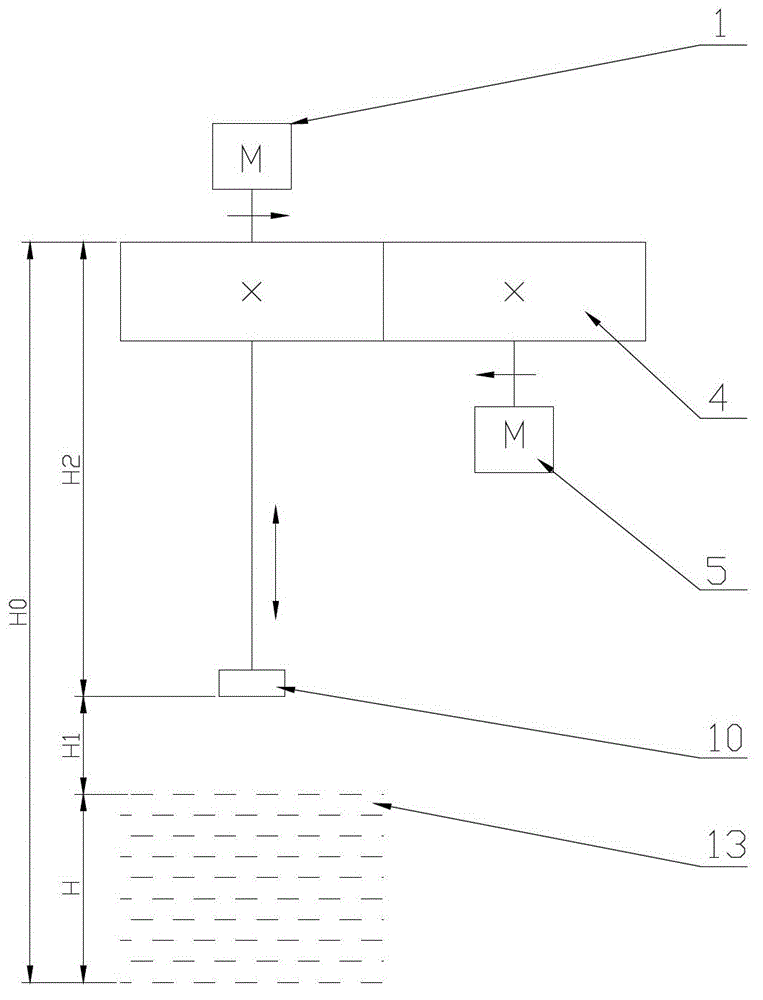

[0028] Such as figure 1As shown, the non-contact single-point liquid metal liquid level device implemented in the present invention includes: a first DC stepping motor 1, a second DC stepping motor 5, a first seal 2 and a second seal 7, and a circuit box 3. Meshing gear 4, sealing shell 6, upper flange 8, lower flange 9, induction probe 10, lifting sleeve 11 and two liquid level probes 12. The lower flange 9 is fixed on the upper edge of the measured container 14, the liquid level probe 12 is fixed on the outer end of the lifting sleeve 11 by screw connection, and the induction probe 10 is fixed on the inner end of the lifting sleeve 11 by interference fit. The bushing 11 is fixed on the upper flange 8 and the lower flange 9 by bearings, the upper flange 8 and the lower flange 9 are connected by screws, and the upper flange 8 and the lower flange 9 are sealed by the second sealing member 7. The end of the casing 11 is connected to a pair of meshing gears 4 (including a drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com