Float-type liquidometer with buoy for high-temperature high-pressure medium or high-pressure low-density medium

A liquid level gauge and float type technology, which is applied in the field of liquid level measurement, can solve the problems of limiting the use temperature of the liquid level gauge, many parts in the float chamber, and inconvenient transportation, so as to improve measurement accuracy and sensitivity, save expensive metal materials, and improve transportation. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

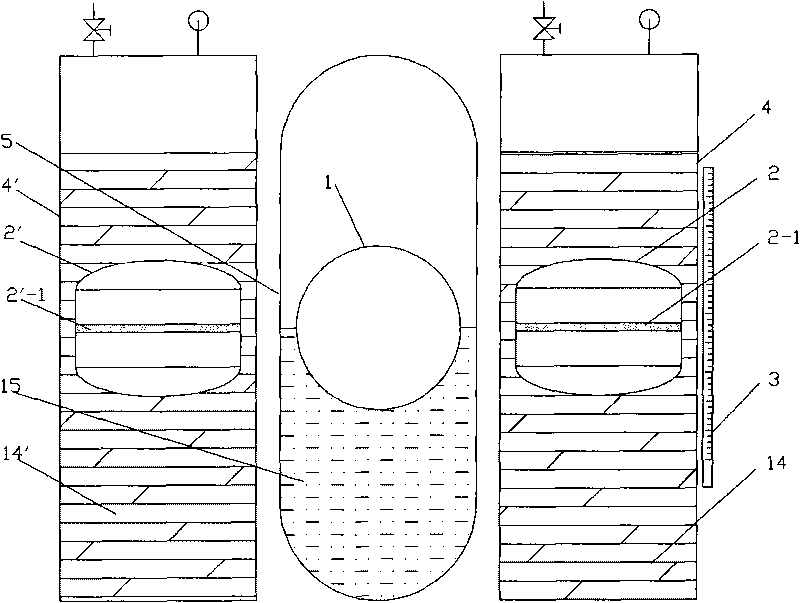

Embodiment 1

[0064] A float type liquid level gauge, such as figure 1 Shown, comprise the float chamber 5 that nonferromagnetic material is made, the float 1 that the ferromagnetic material in float chamber 5 is made, the float chamber 4 that nonferromagnetic material is made outside float chamber 5, wherein be filled with liquid medium 14, built-in magnetic The buoy 2 of the steel 2-1 floats in the liquid medium 14, the magnetic steel 2-1 is close to the float 1; The specific gravity of the buoy is smaller than the specific gravity of the liquid 14 in the buoy chamber, and the buoyancy of the buoy 2 minus the gravity of the buoy 2 is equal to the gravity of the buoy 1 minus the buoyancy of the buoy when the buoy 1 is immersed in about half of the liquid 15 . The buoy 1 and the buoy 2 achieve force balance through magnetic coupling force, that is, the buoy 2 gives the buoy 1 an upward lifting force through the magnetic attraction force with the buoy 1 .

[0065] In order to further increa...

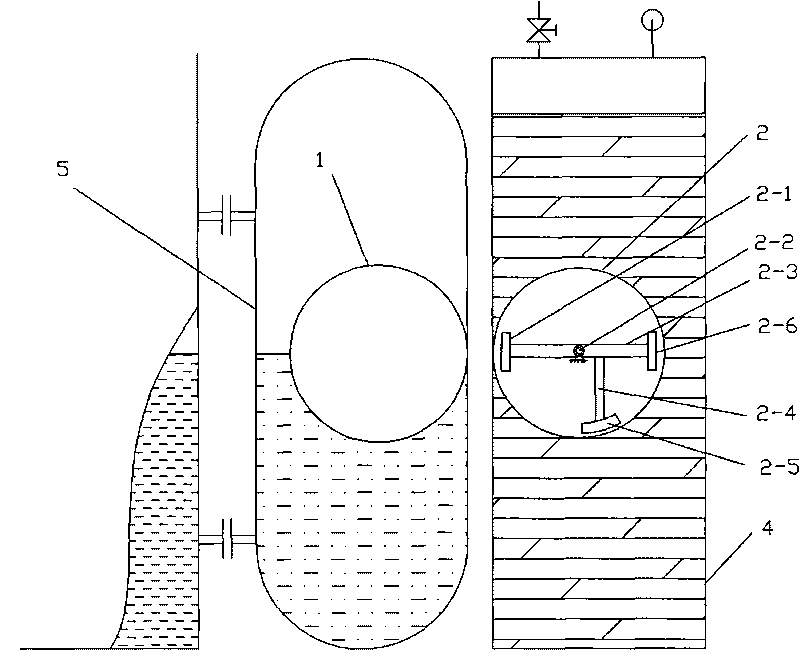

Embodiment 2

[0071] Such as figure 2 In the float type liquid level gauge shown, in order to further reduce the friction between the buoy 2 and the buoy chamber 4 and improve the accuracy, the sliding friction between the buoy 2 and the buoy chamber 4 is changed into rolling friction, and the characteristic is that the float 1 is A hollow spherical float 1 made of ferromagnetic material, buoy 2 is a hollow cylinder or hollow sphere made of non-ferromagnetic material with a horizontal axis, and there is a horizontal rod fixed on the axis or center of the inner cavity of buoy 2 in buoy 2 Axis 2-2 on the line. A horizontal connecting rod 2-3 perpendicular to the shaft is fixed at the axial center point of the shaft 2-2, and the end of the horizontal connecting rod 2-3 near the float 1 is equipped with a magnetic pole facing the magnetic steel 2-1 of the float 1, and its corresponding The other end is fixed with a balance magnet or a balance weight 2-6; the lower part of the horizontal conne...

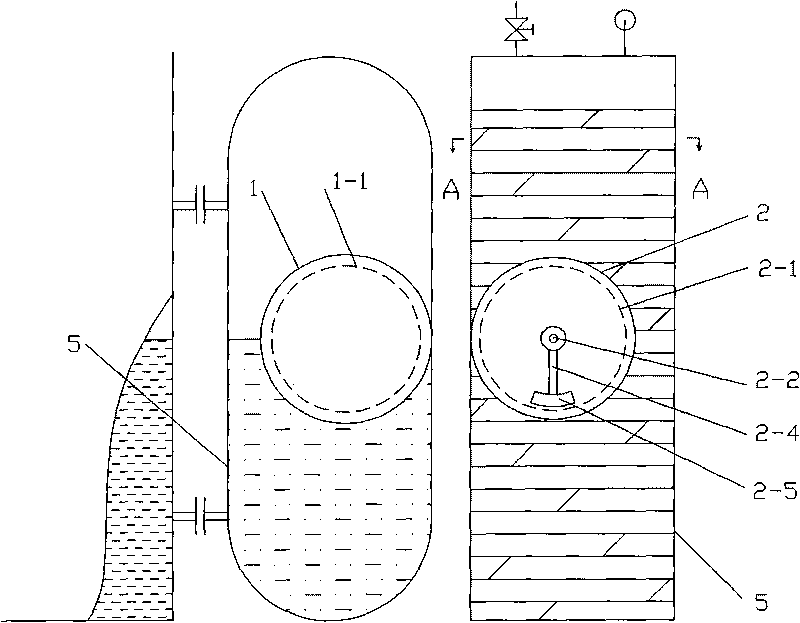

Embodiment 3

[0076] Such as image 3 , The float type liquid level gauge shown in 4 and 5 is suitable for occasions where the temperature of the medium will not cause demagnetization of the magnetic steel, including the float chamber 5 and the float 1 inside, the float chamber 4 and the buoy 2 inside, the said Float 1 is made of non-ferromagnetic material. Float 1 is equipped with one or several pieces of disc-shaped magnetic steel A1-1 with the same inner diameter as float 1. Float 2 is a hollow cylinder made of non-ferromagnetic material with a horizontal axis. Or a hollow sphere, the buoy 2 is fixed with a disc-shaped magnetic steel B2-1 with the same inner diameter as the buoy 2 . The axes of magnet A and magnet B are parallel to each other and to the ground. The magnetic poles of the two are respectively located on the axial end faces of their disc-shaped structures, and the N and S poles of the two are oppositely arranged. The axes of magnets A and B are The vertical planes lie on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com