Optical fiber liquid level measurement device and method

A liquid level measurement device and optical fiber technology, applied in the field of optics, can solve problems such as high manufacturing process requirements, small measurement range, and application limitations, and achieve high-precision liquid level measurement, simple production, and high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

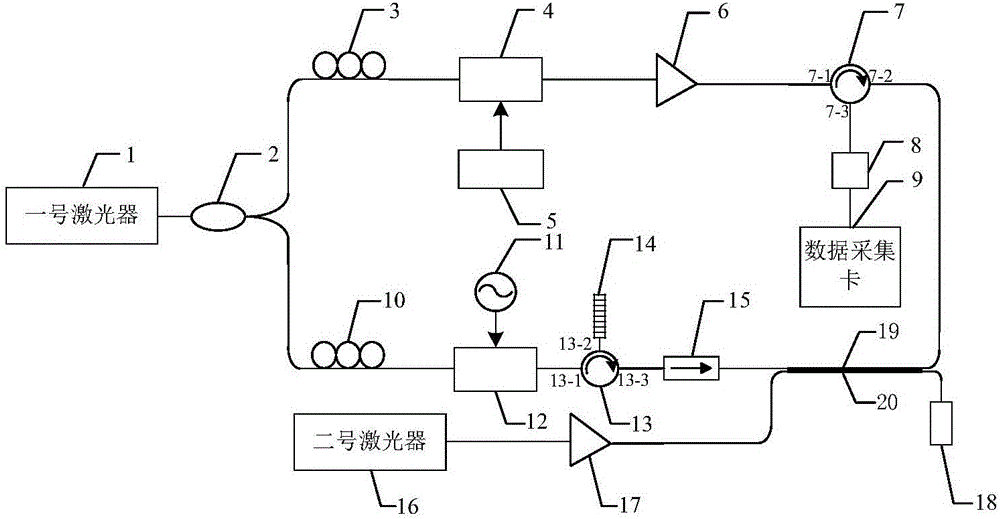

[0026] Specific implementation mode one: refer to figure 1Describe this embodiment, the optical fiber liquid level measuring device described in this embodiment includes No. 1 laser 1, No. 2 laser 16, fiber coupler 2, No. 1 polarization controller 3, No. 2 polarization controller 10, No. 1 Electro-optic modulator 4, No. 2 electro-optic modulator 12, No. 1 erbium-doped fiber amplifier 6, No. 2 erbium-doped fiber amplifier 17, microwave source 11, arbitrary function generator 5, No. 1 circulator 7, No. 2 circulator 13, Fiber Bragg grating 14, optical isolator 15, sensing fiber 19, self-heating fiber 20, photodetector 8, data acquisition card 9 and power meter 18; optical signal output port of No. 1 laser 1 and input port of coupler 2 connected, the two signal output ports of coupler 2 divide the light into upper and middle light, the upper light provides pump light to communicate with No. 1 polarization controller 3, and No. 1 polarization controller 3 connects with No. The opt...

specific Embodiment approach 2

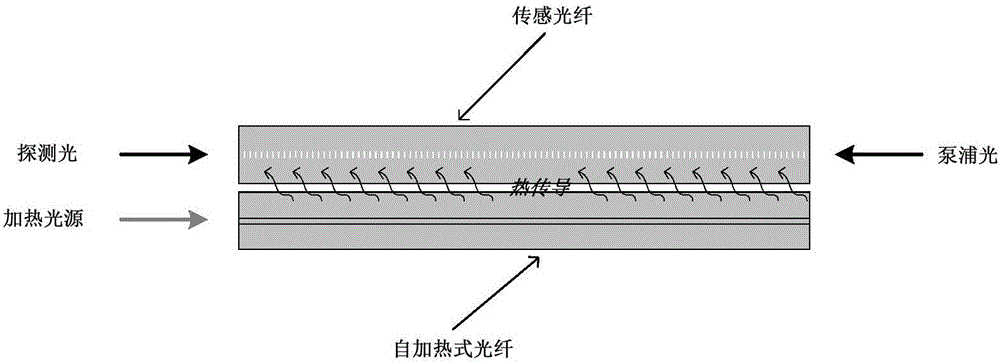

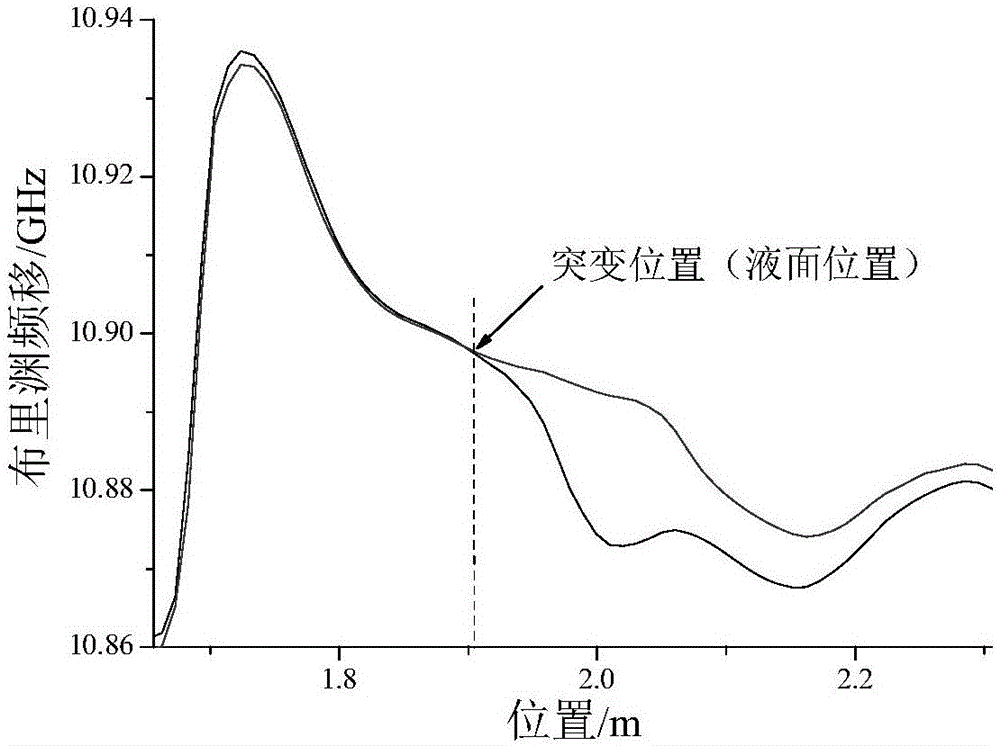

[0029] Specific implementation mode two: combination image 3 This embodiment is described. This embodiment is a further limitation of the specific embodiment—an optical fiber liquid level measuring device. The sensing optical fiber 19 is immersed in the liquid to be measured. The interface will form a temperature mutation point; the Brillouin frequency shift at each position of the sensing fiber is obtained by frequency sweeping. Since the Brillouin frequency shift of the fiber has a linear relationship with the temperature, the temperature mutation is reflected as the Abrupt changes in the Brillouin shift in position. Therefore, the abrupt position of the Brillouin frequency shift measured on the optical fiber is the position of the liquid level.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is a further limitation of the embodiment—an optical fiber liquid level measuring device. The sensing optical fiber 19 is a panda-type polarization-maintaining optical fiber, and its Brillouin frequency shift is 10.88 GHz at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com