Method for determining whether liquid accumulation exists in gas well or not and determining liquid accumulation degree

A technology for gas wells and liquid accumulation, which is applied in determining whether gas wells accumulate liquid and the degree of liquid accumulation, and in the field of liquid accumulation gas wells, can solve the problems of expensive implementation process, unfavorable low-cost development of gas fields, etc., and achieves low cost, simple method and principle. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for determining whether a gas well has fluid accumulation and the degree of fluid accumulation, including the following steps,

[0031] Step 1: Check the production data of the gas well and obtain the oil pressure when the gas well is shut down , sleeve pressure , gas density and liquid density ;

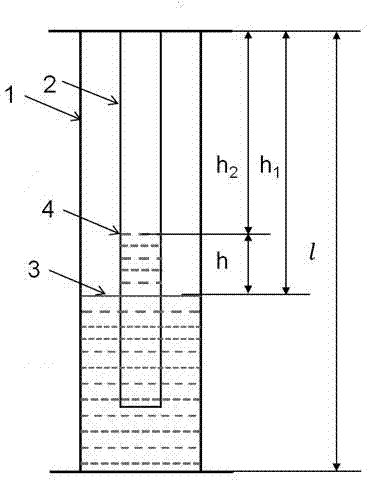

[0032] Step 2: Using the data measured in Step 1, calculate the liquid level difference h between the liquid column in the oil pipe and the liquid column in the annular space of the oil jacket, as shown in figure 1 shown;

[0033] Calculate the liquid level difference h between the depth of the liquid column liquid level 4 in the tubing 1 and the depth of the liquid column liquid level 3 in the oil casing annulus in the casing 2, through the following calculation,

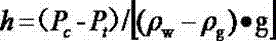

[0034] (3)

[0035] In the formula: ——liquid density, kg / ;

[0036] ——Gas density, kg / ;

[0037] g—gravitational acceleration, m / ; ...

Embodiment 2

[0048] In the above embodiment, the method for determining whether the gas well has fluid accumulation and the degree of fluid accumulation may also include:

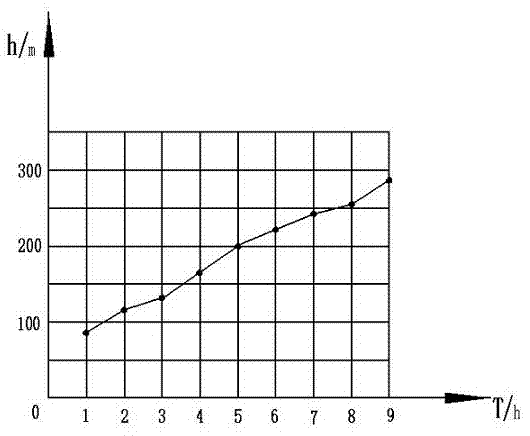

[0049] Step 4: Measure and calculate the liquid level difference h multiple times, and draw the liquid level difference h obtained multiple times into a curve corresponding to time, so as to prove the change law of the liquid accumulation degree in the wellbore of the gas well and determine the gas production measures of the gas well.

[0050] For example, in the Sulige gas field, when the height of the effusion, that is, the height of the liquid level difference h calculated in the above-mentioned embodiment is less than 500m, it is normal. According to the calculation, before the height of the liquid accumulation exceeds 500m, liquid drainage measures should be taken. Chemical agents can be added to drain the gas to reduce the amount of liquid accumulation and avoid gas well crushing.

[0051] The following will be de...

Embodiment 3

[0053] Oil pressure of a gas well during shut-in 5.8MPa, sleeve pressure is 7.2MPa, liquid density 1010kg / , gas density 610 kg / . Substitute the above information into the formula:

[0054]

[0055] The liquid column difference h between the tubing and the casing annulus is calculated to be 350m.

[0056] If the local allowable height of effusion is 500m, then in this case, normal gas production can still be carried out, and there is no need to clear the effusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com