Rotary type air pre-heater and secondary air side air-leaking-reducing and plugging-preventing method thereof

An air preheater, rotary technology, applied in regenerative heat exchangers, combustion methods, indirect heat exchangers, etc., can solve the surface pollution of heat exchange elements, reduce the load capacity of the unit, and increase power consumption, etc. problems, to achieve the effect of NOX generation inhibition, solving the problem of ash blocking, and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

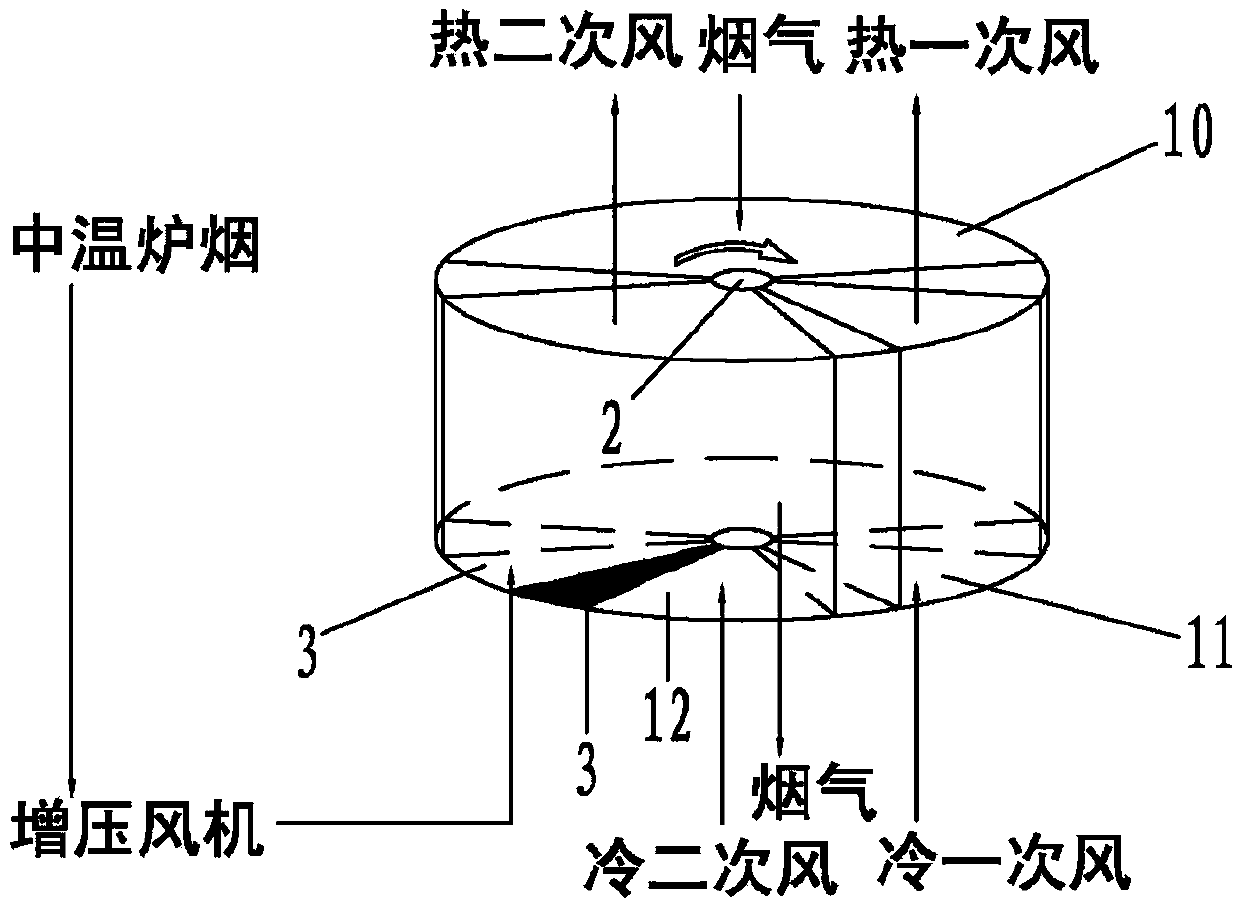

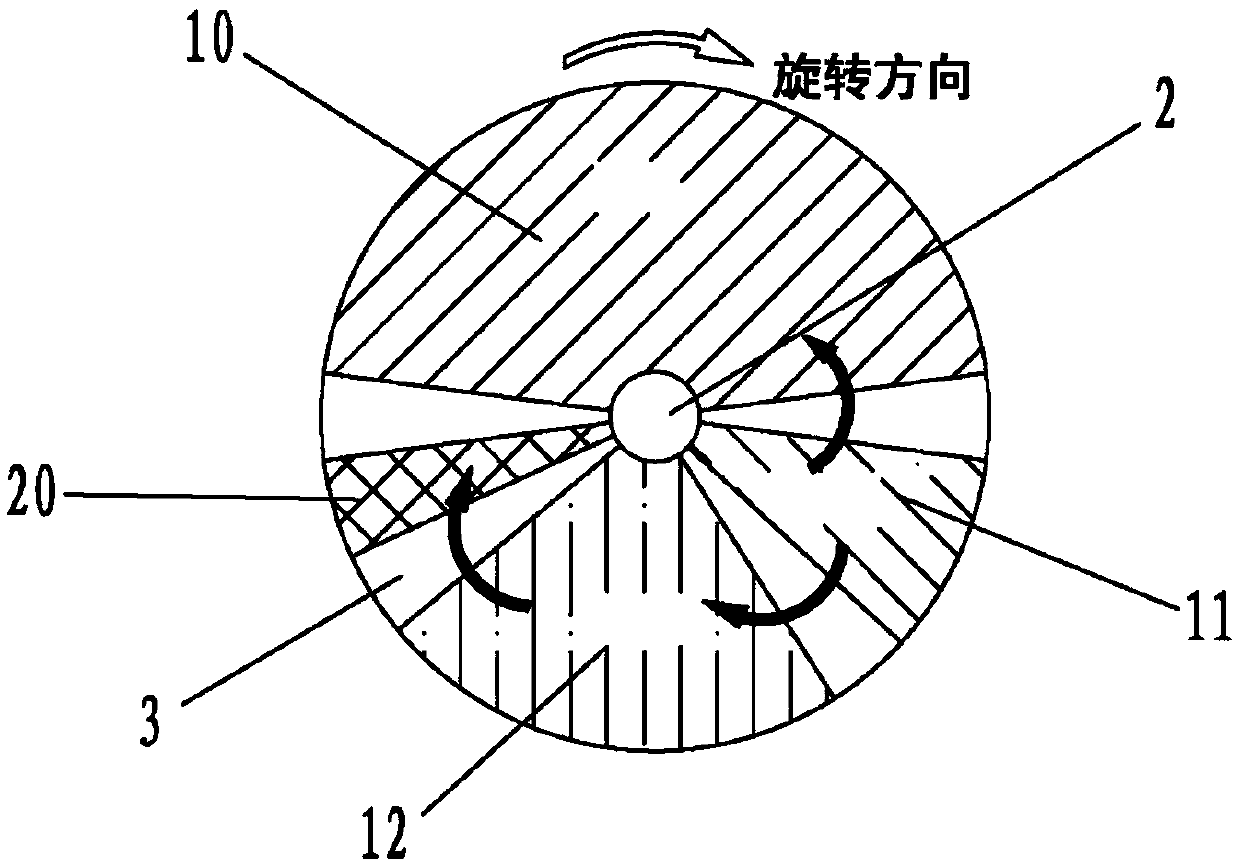

[0030] Such as figure 1 , figure 2 As shown, the rotary air preheater of the present invention includes a chamber and a rotor 2 rotatably arranged in the center of the chamber. The rotor 2 is provided with heat exchange elements. The fan-shaped flue gas bin 10, the primary air bin 11, and the secondary air bin 12, the flue gas bin 10, the primary air bin 11, and the secondary air bin 12 are arranged circumferentially around the rotor in turn and are all adjacent to the rotor 2, and the primary air bin Adjacent to the secondary air chamber, a radially extending fan-shaped partition 3 is arranged in the secondary air inlet at the bottom of the secondary air chamber. The fan-shaped partition 3 separates the secondary air chamber into a fan-shaped heating compartment 20, and the heating partition One radius side of the bin 20 is adjacent to the flue gas bin, the short arc side of the heating compartment is adjacent to the rotor, the air inlet of other parts of the secondary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com