Thermal washing and paraffin removal device for oil well

A technology of hot washing and wax removal, which is applied in the direction of isolation devices, wellbore flushing, wellbore/well parts, etc. It can solve problems such as affecting production, wasting energy, explosion, etc., and achieves fuel saving, convenient transportation, and safe process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

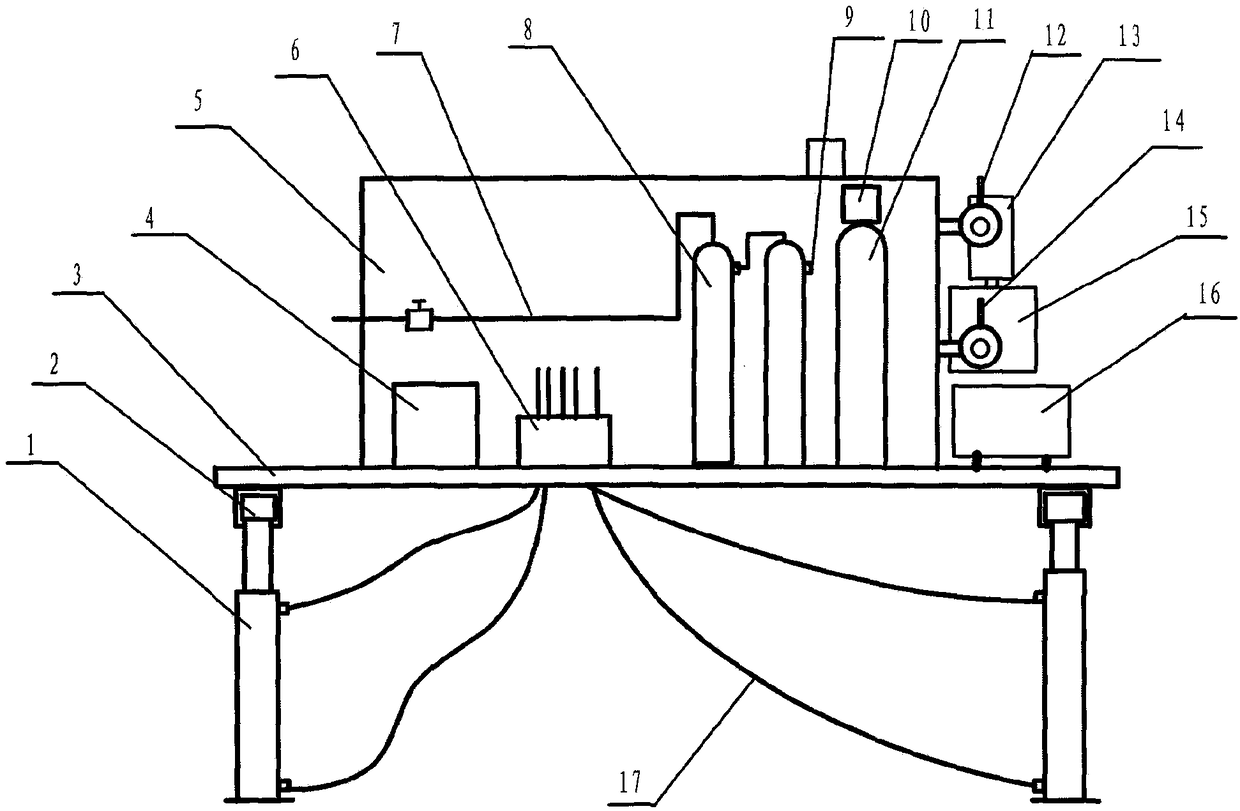

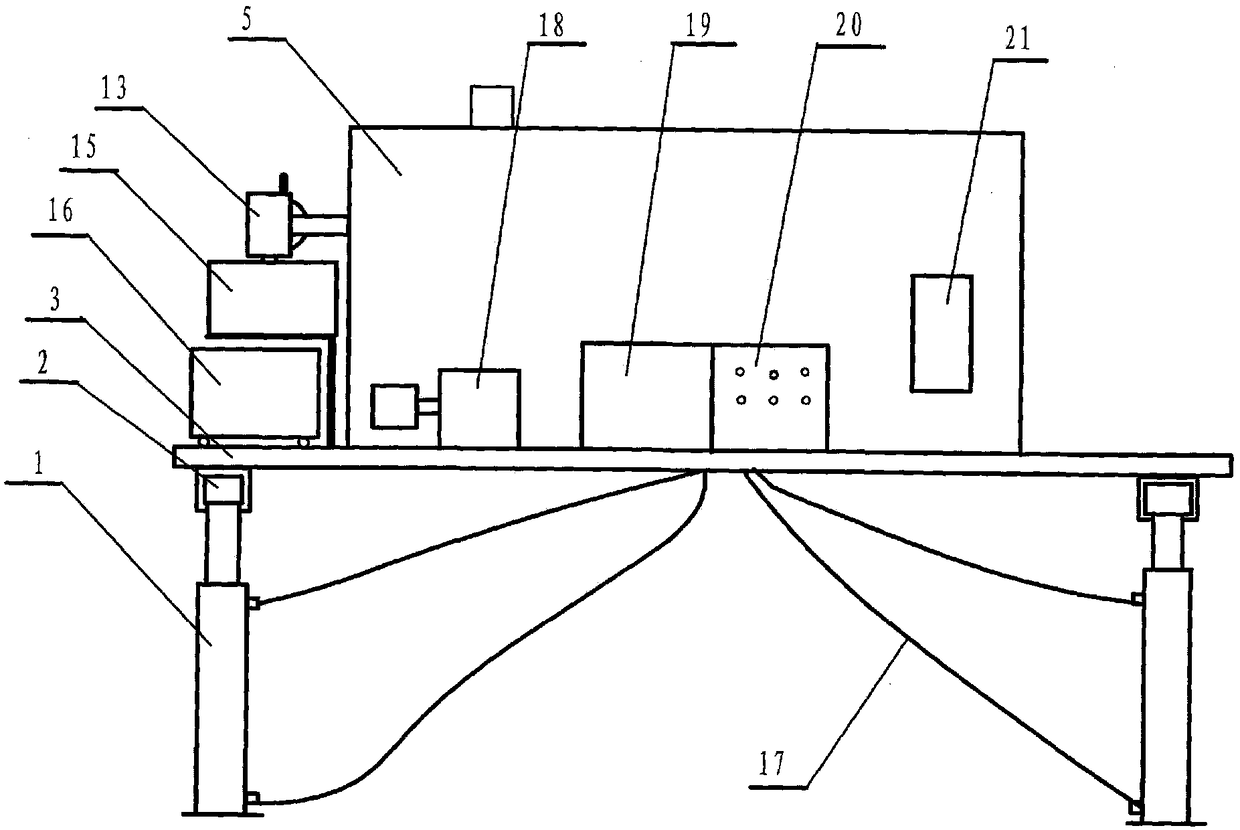

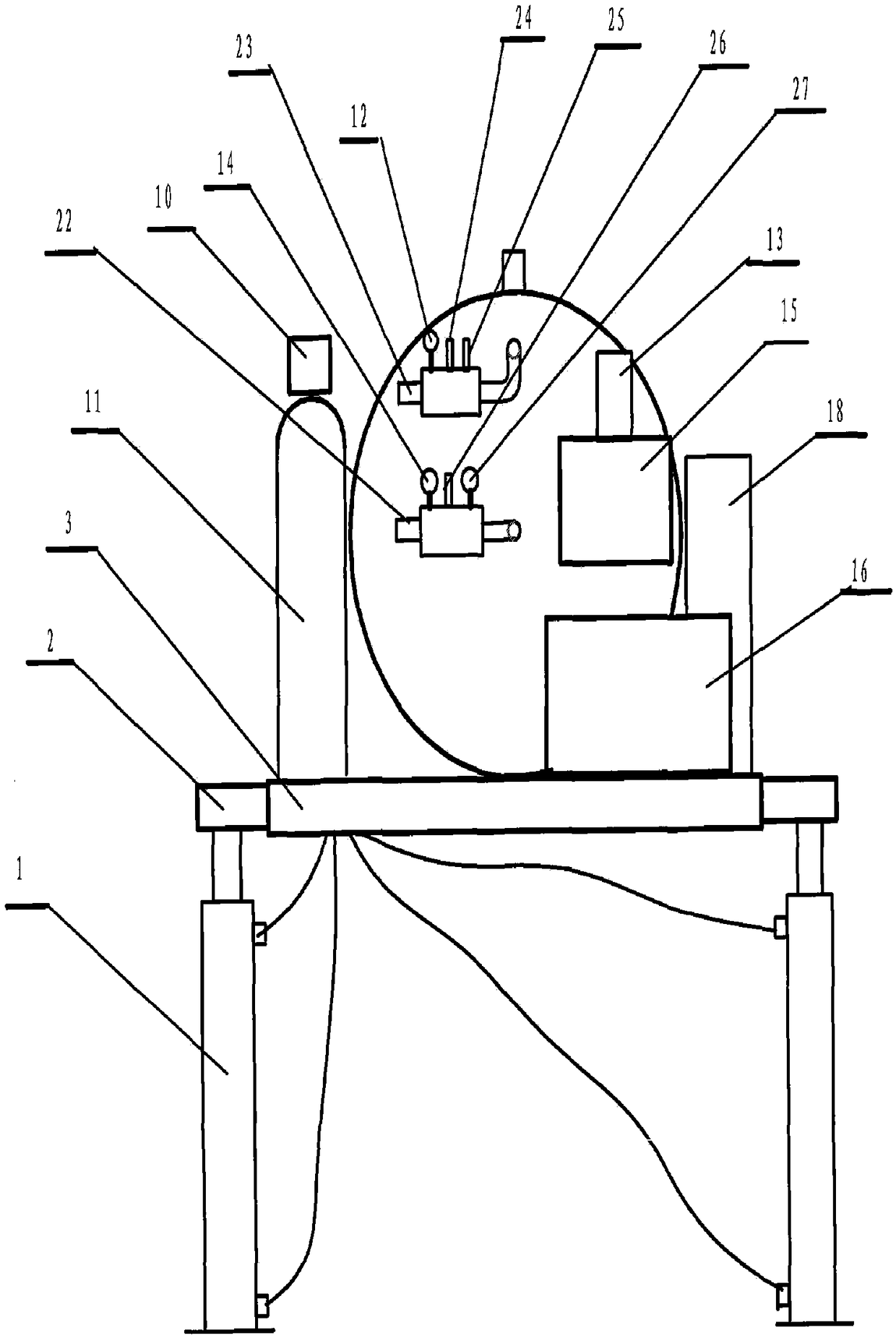

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as Figure 1~3 As shown, the oil well thermal wax removal device provided by the present invention includes a base plate 3, a heating furnace 5 is installed in the middle of the base plate 3, and a natural gas purification tank 8, a softened water tank 11, a plunger pump 18, an intelligent Control box 19, power switchboard 20, hydraulic control valve 6; telescopic rod 2 is installed on the four corners of bottom plate 3, and hydraulic prop 1 is installed under the end of each telescopic rod 2, and wheels are installed on the bottom of hydraulic prop 1, and wheels are installed on the wheels. There is a fixed locking device; a push-pull rod is installed on one side of the base plate 3; the hydraulic pump is connected to the motor 13 through a shaft, the motor 13 is installed on the fuel tank 15, the fuel tank is installed on the base plate, and the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com