Movable charging battery chemical synthesizing method synthesizer

A technology of rechargeable battery and chemical formation method, which is applied in the direction of secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of inability to guarantee the quality of rechargeable batteries, low sorting efficiency, and easy misoperation, etc. To achieve the effect of easy management, reduce operators and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

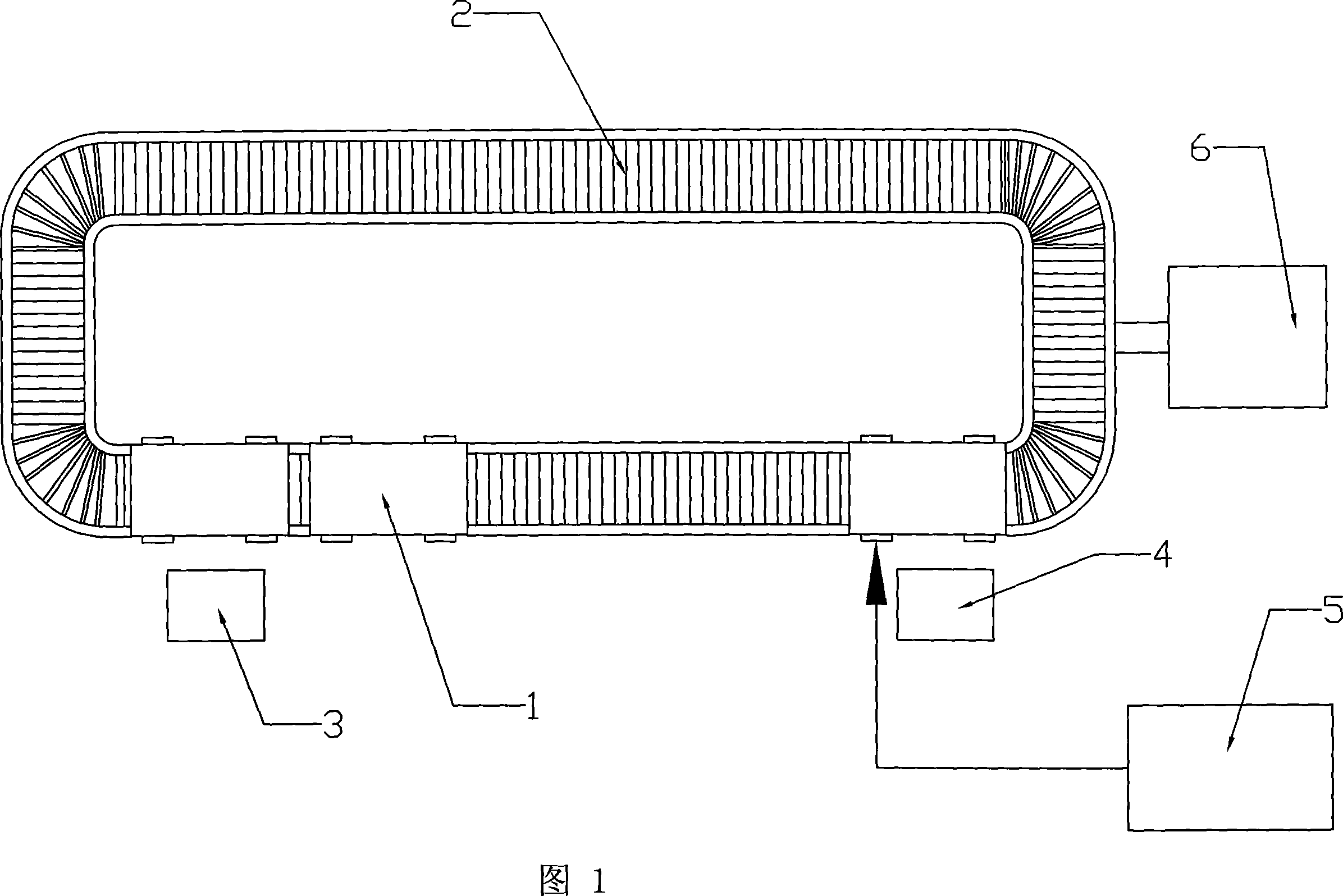

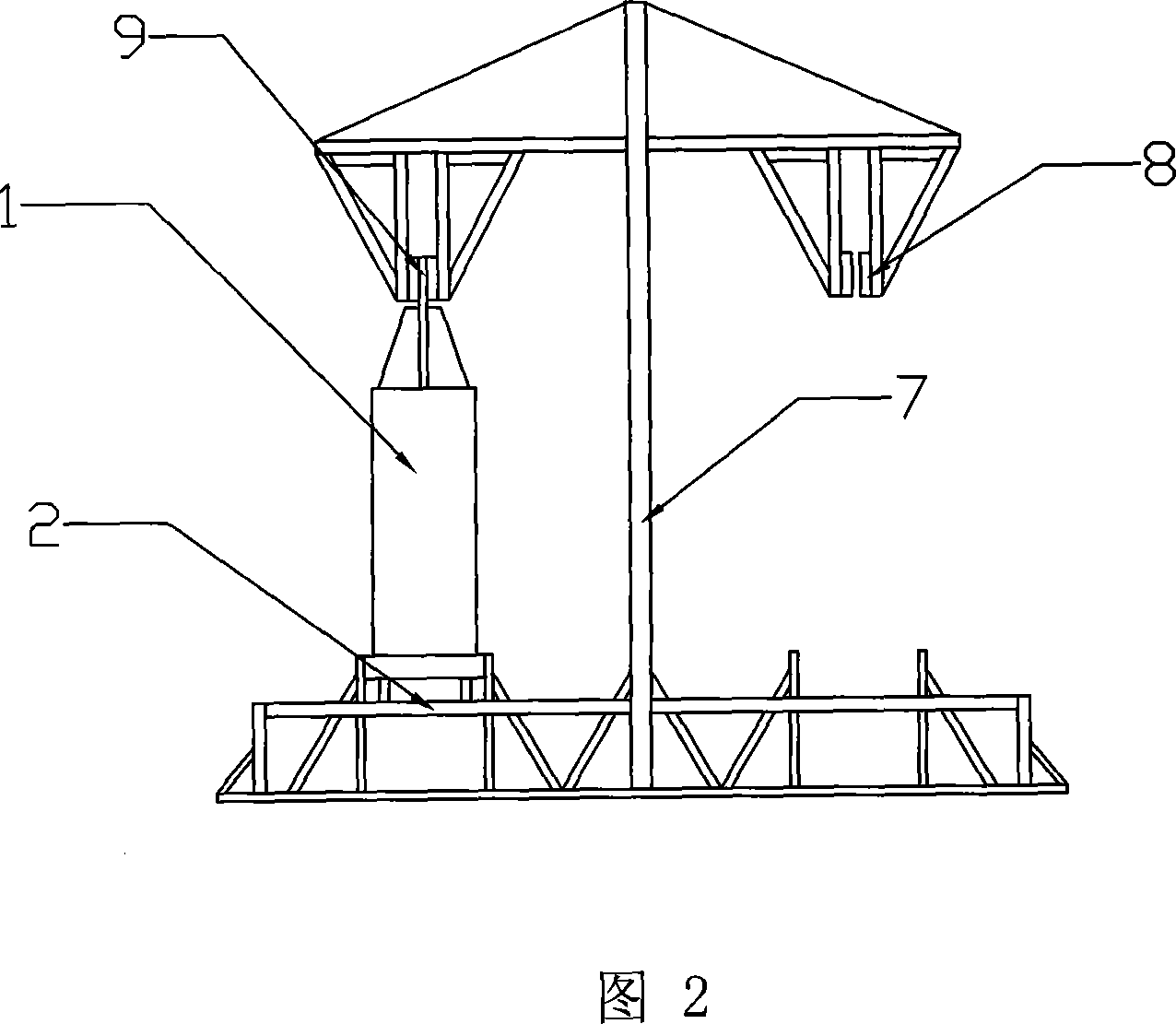

[0012] Referring to Fig. 1, the mobile formation method of rechargeable batteries involves moving a plurality of charging and discharging equipment 1 on a predetermined track 2, and setting a battery installation station 3 and a battery sorting station 4 along the moving route. When the charging and discharging equipment 1 moves When the battery installation station 3 is reached, the rechargeable battery that needs to be formed is installed on the charging and discharging device 1, and charging and discharging are performed during the moving process. When the charging and discharging device 1 moves to the battery sorting station 4, the batteries are sorted and disassembled. Since the charging and discharging equipment moves on the track, it is only necessary to set up the battery installation station and the battery sorting station along the moving route, and then equip a small number of operators at the stations. When the charging and discharging equipment moves to the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com