Method for effective sterilization and efficient hydration of primary sludge

A high-efficiency technology for primary sludge sedimentation, applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problems of high operating cost, pollution, and difficulty in dewatering, and achieve a one-time investment Less, good working environment, uniform and thorough sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

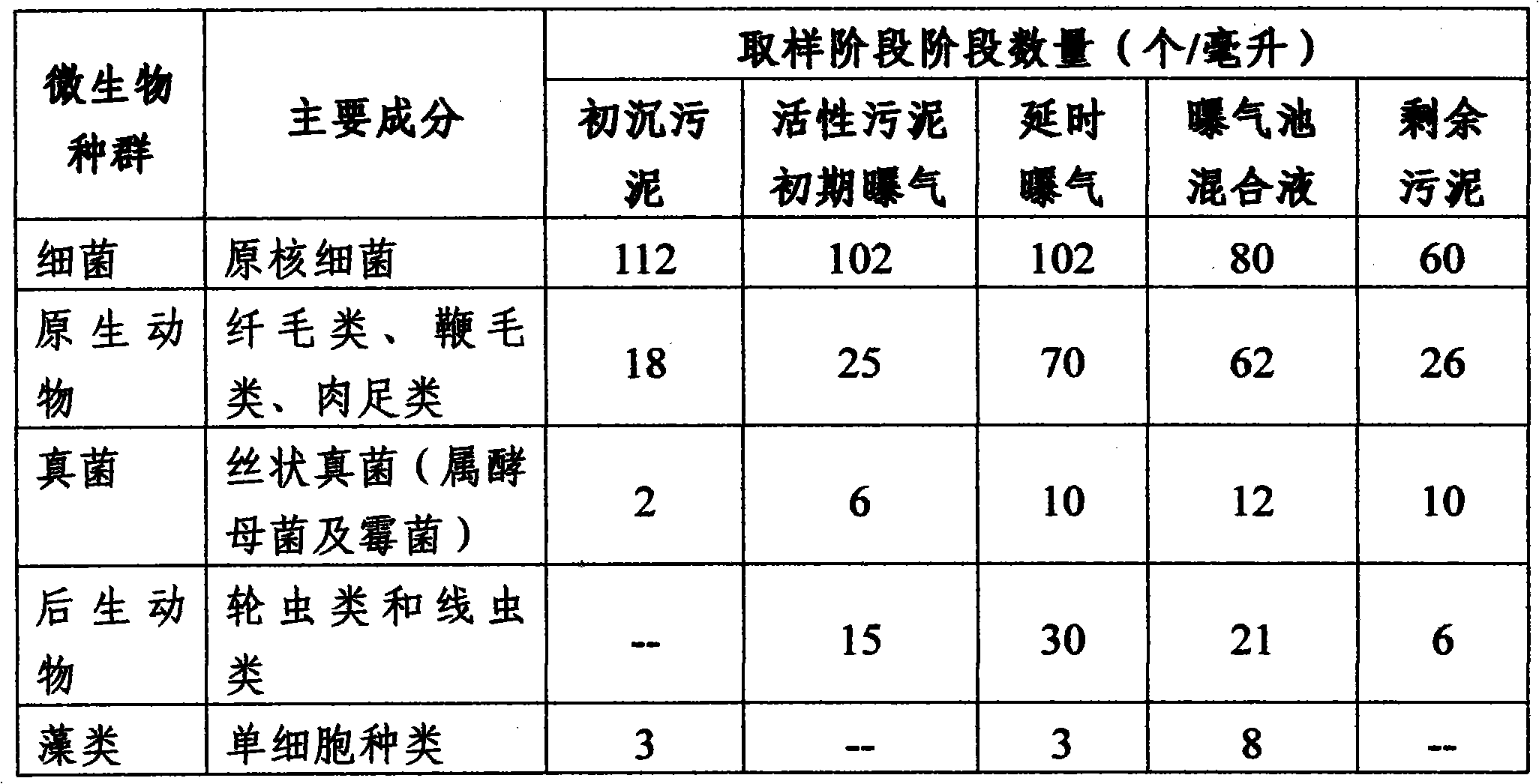

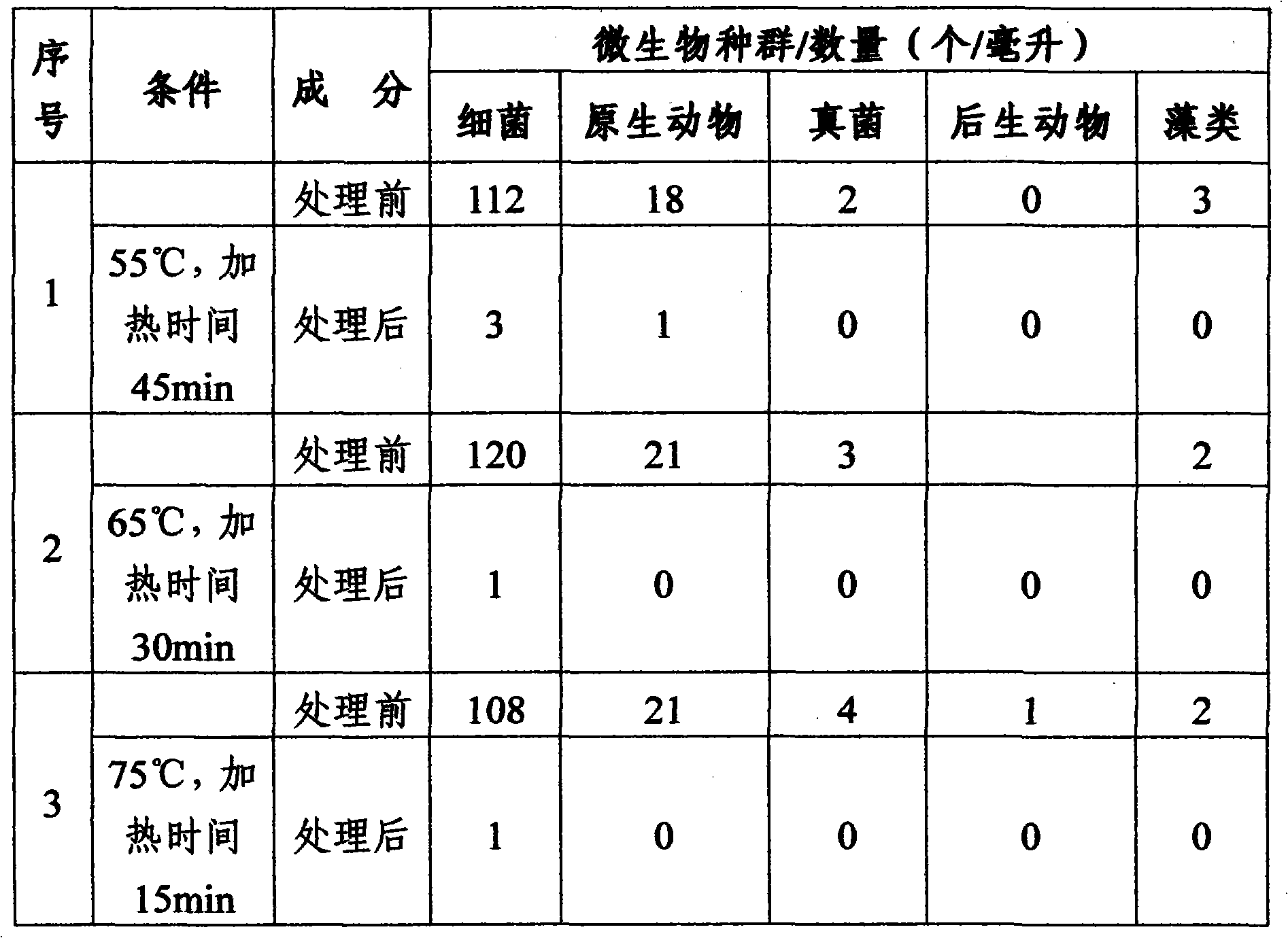

[0029] Example 1 The primary sludge sample was taken from a sewage treatment plant in Xingsha, Hunan, with a water content of 97.5% and a solid content of 2.5%. Samples for identification were taken in June 2010, respectively in primary sludge, initial aeration of activated sludge, delayed aeration of low-load activated sludge system, mixed solution of aeration tank of activated sludge, residual sludge Sampling was carried out in five processing stages, and the pure species were isolated according to the conventional microbial operation method at the beginning of the identification through the MicroStation automatic rapid microbial identification instrument. The identification steps are as follows:

[0030] 1. Plate expansion culture: use BIOLOG special medium to expand the pure species;

[0031] 2. Prepare bacterial suspension: prepare bacterial suspension with a certain turbidity (cell concentration) as required;

[0032] 3. Inoculation and cultivation: inoculate the bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com