Seismic exploration submarine cable recycling and coiling device

A submarine cable and seismic exploration technology, applied in the field of petroleum seismic exploration, can solve problems affecting work efficiency, bending resistance, weak tensile strength, cable damage, etc., to reduce labor intensity, increase the number of wrapping angles, and save the number of operators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

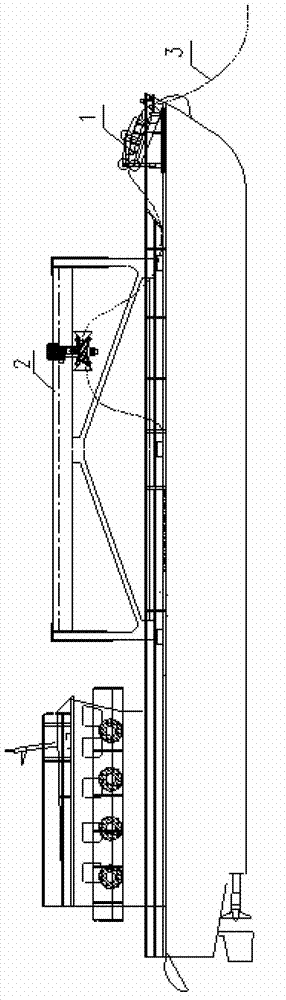

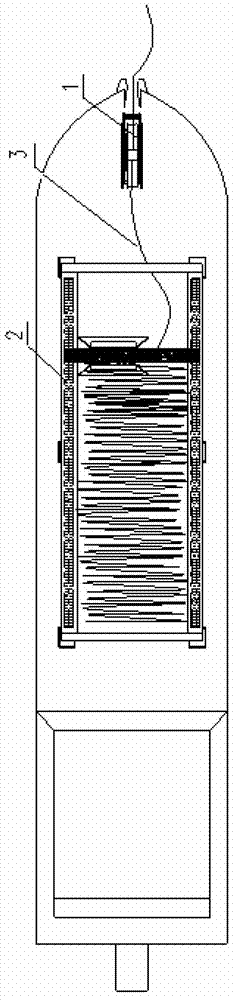

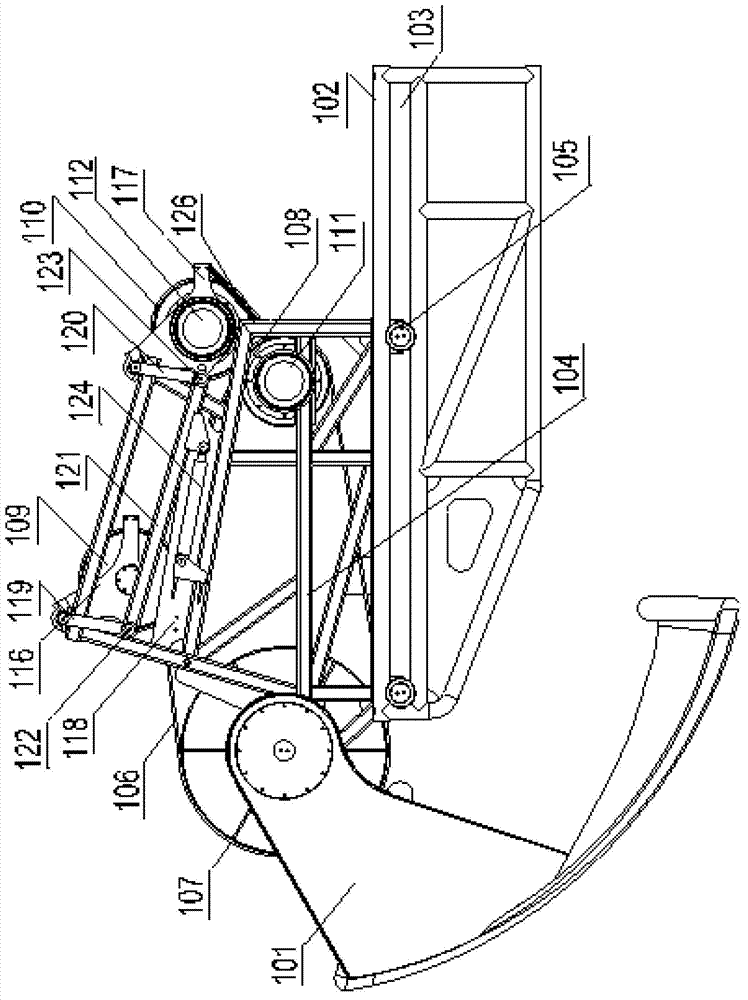

[0034] Embodiment 1: Taking the submarine cable recovery device for the seismic exploration of the cable-laying ship 30 as an example, the present invention will be further described in detail.

[0035] See Figure 1. The submarine cable recovery device for seismic exploration of the present invention is composed of a bow crawler type cable receiving machine 1 and a hanging type cable coiling machine 2. Track pulley 105, rubber track 106, driven roller 107, driving roller 108, driven roller 109, driving roller 110, driving roller hydraulic motor 111, driving roller hydraulic motor 112, first parallel roller 113, second Parallel roller 114, third parallel roller 115, driven roller hanger 116, driving roller hanger 117, track guard 118, driven roller connecting rod 119, driving roller connecting rod 120, roller lifting Lifting connecting rod 121, driven pressure roller lifting shaft 122, active pressure roller lifting shaft 123, pressure roller lifting hydraulic cylinder 124, el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com