Positioning structure and positioning method for casting castings

A positioning structure and positioning method technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve problems such as waste of manpower, easy collision, casting runaway, etc., to improve operating efficiency, avoid collisions, and avoid deviations The effect of box wrong type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

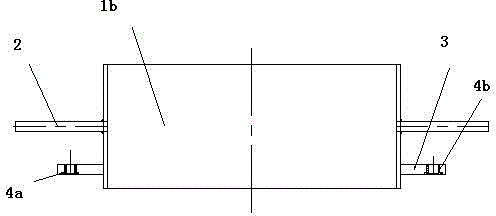

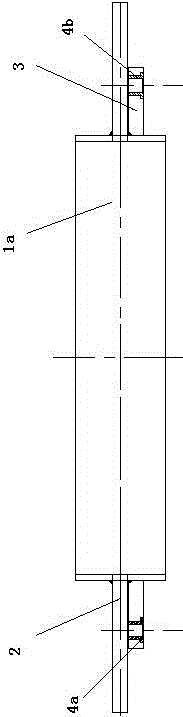

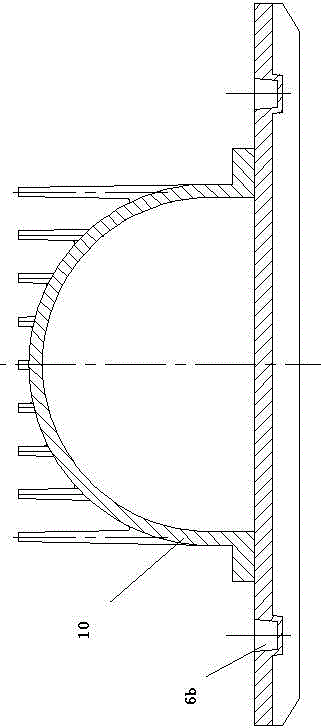

[0036] The following combination Figure 1-Figure 13 Specific embodiments of the present invention will be described in detail.

[0037] In the implementation process of the present invention, at first need to manufacture the upper mold and lower mold of mould, then utilize upper mold to form upper sand mold in upper sand box, utilize lower mold to form lower sand mold in lower sand box, then utilize upper mold and lower sand box The sand box is closed. After the box is closed, the molten liquid is poured from the sand gate into the gap formed by the sand mold. After cooling, the sand mold space will form a casting. The concave-convex shape in the above mold is consistent with the concave-convex shape in the sand box, and the direction is opposite. The positioning concave platform (boss) will be formed in the sand box. The positioning concave platform and the positioning convex platform in the sand box are matched with each other after the box is closed. In the following desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com