A kind of assembly method of ring mold movable block group

An assembly method and technology of live blocks, which are applied in the directions of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of affecting the normal assembly of molds, difficult positioning, and difficult assembly, so as to avoid the problem of wrong type of assembly molds and simple positioning operation. The effect of fast and improved mold assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

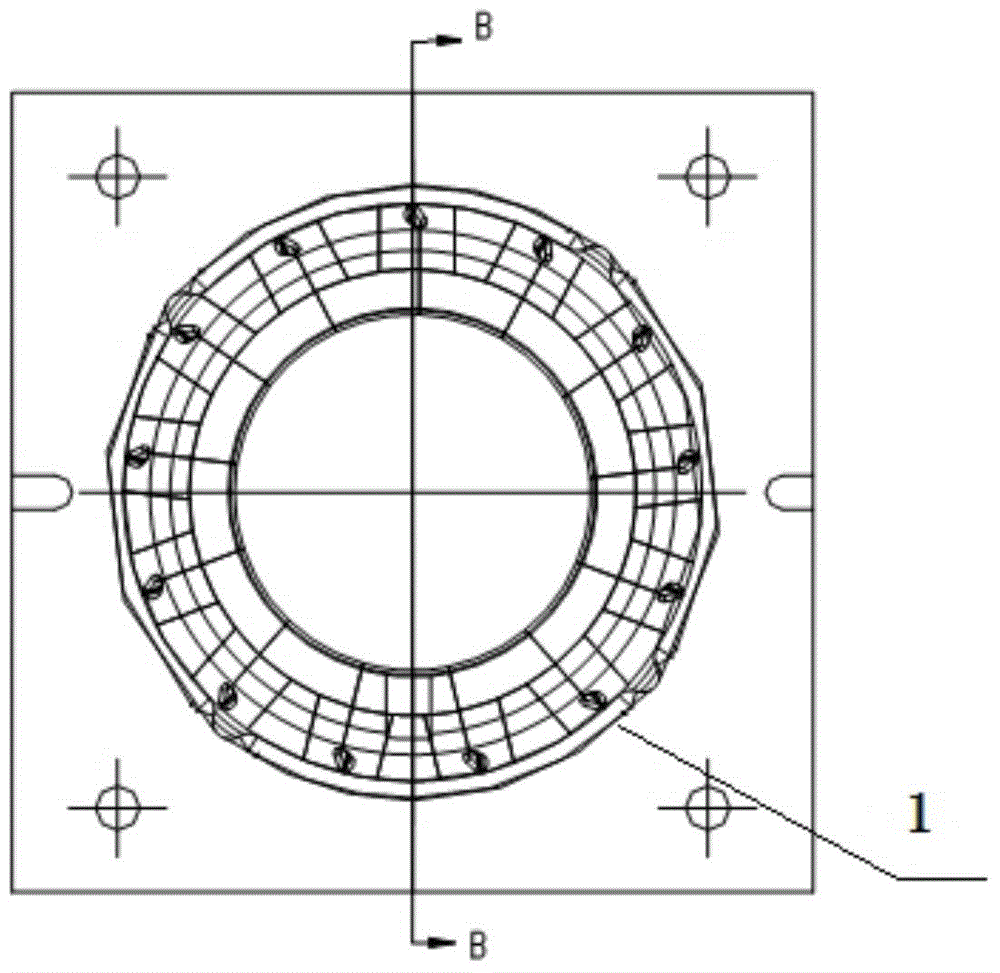

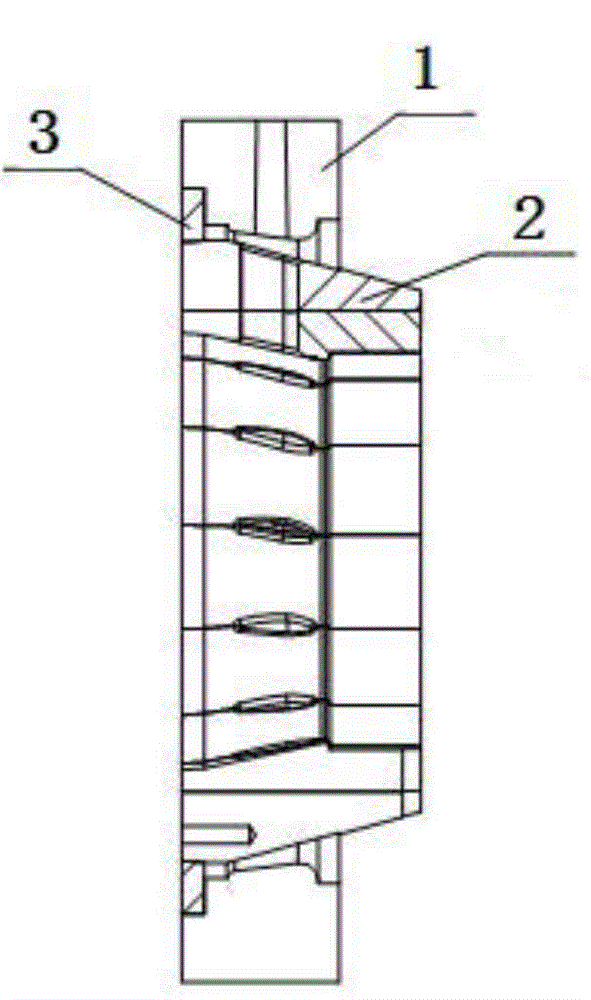

[0013] Such as figure 1 As shown in the figure, a method for assembling the movable block group of the ring mold, before the ring mold (1) is assembled, a positioning ring (3) is made according to the structural shape of the movable block group (2), and the inner part of the positioning ring (3) The circular surface corresponds to the shape of the corresponding mating surface of the movable block group (2), and the outer circular surface of the positioning ring (3) corresponds to the shape of the corresponding mating surface of the upper and lower half molds of the ring mold (1). After the block groups (2) are snapped into the positioning ring (3) for positioning one by one, the positioning ring (3) equipped with the movable block group (2) is assembled with the upper and lower half molds of the ring mold (1).

[0014] Further, in this embodiment, a slot is provided on the inner surface of the positioning ring (3), and the movable block group is snapped into the slot for posit...

Embodiment 2

[0017] Such as figure 1 As shown, a method for assembling a ring-shaped mold movable block group, the diameter of the bottom joint surface of the ring-shaped mold (1) is φ136.32mm, and the diameter of the upper joint surface is φ115mm. The upper and lower conical surfaces are 15° and 5° respectively. Before the ring mold (1) is assembled, a positioning ring (3) is made according to the structural shape of the movable block group (2). The inner circle of the positioning ring (3) The surface corresponds to the shape of the corresponding mating surface of the movable block group (2), and the outer circular surface of the positioning ring (3) corresponds to the shape of the corresponding mating surface of the upper and lower half molds of the ring mold (1). After the groups (2) are snapped into the positioning ring (3) for positioning one by one, the positioning ring (3) equipped with the movable block group (2) is assembled with the upper and lower half molds of the ring mold (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com