Guide blade water flow measuring clamp and guide blade water flow measuring method

A technology of guide vanes and measuring fixtures, applied in the directions of measuring capacity, liquid/fluid solids measurement, measuring devices, etc., can solve the problems of complicated operation steps, unstable measurement data, inconvenient use, etc., and achieve high measurement efficiency and measurement data. Stable and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

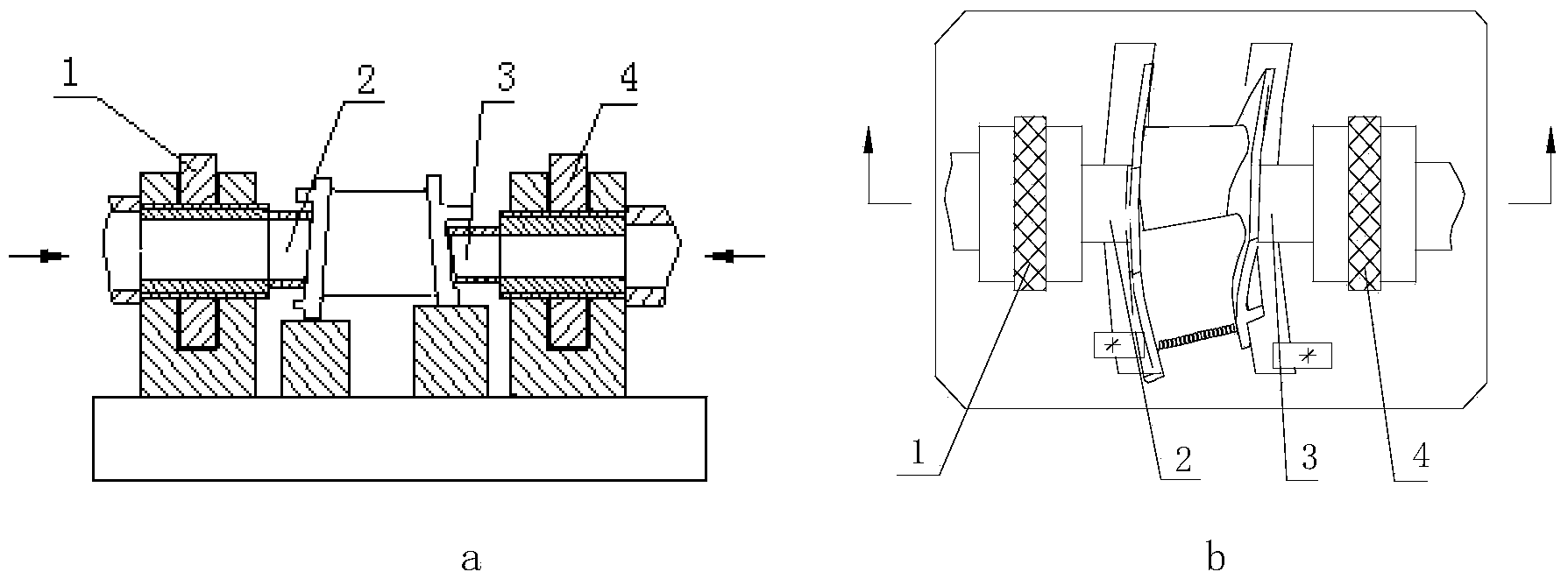

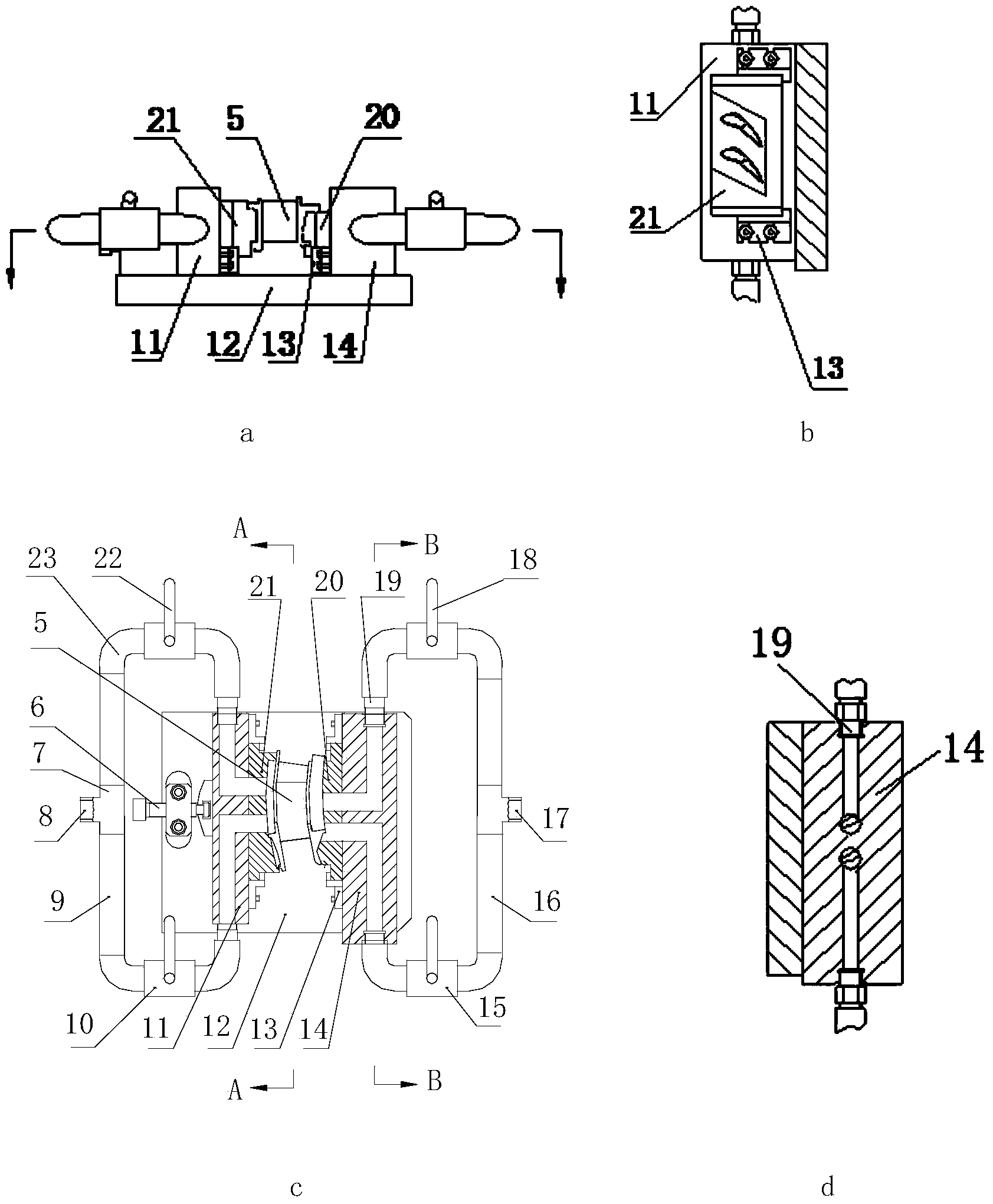

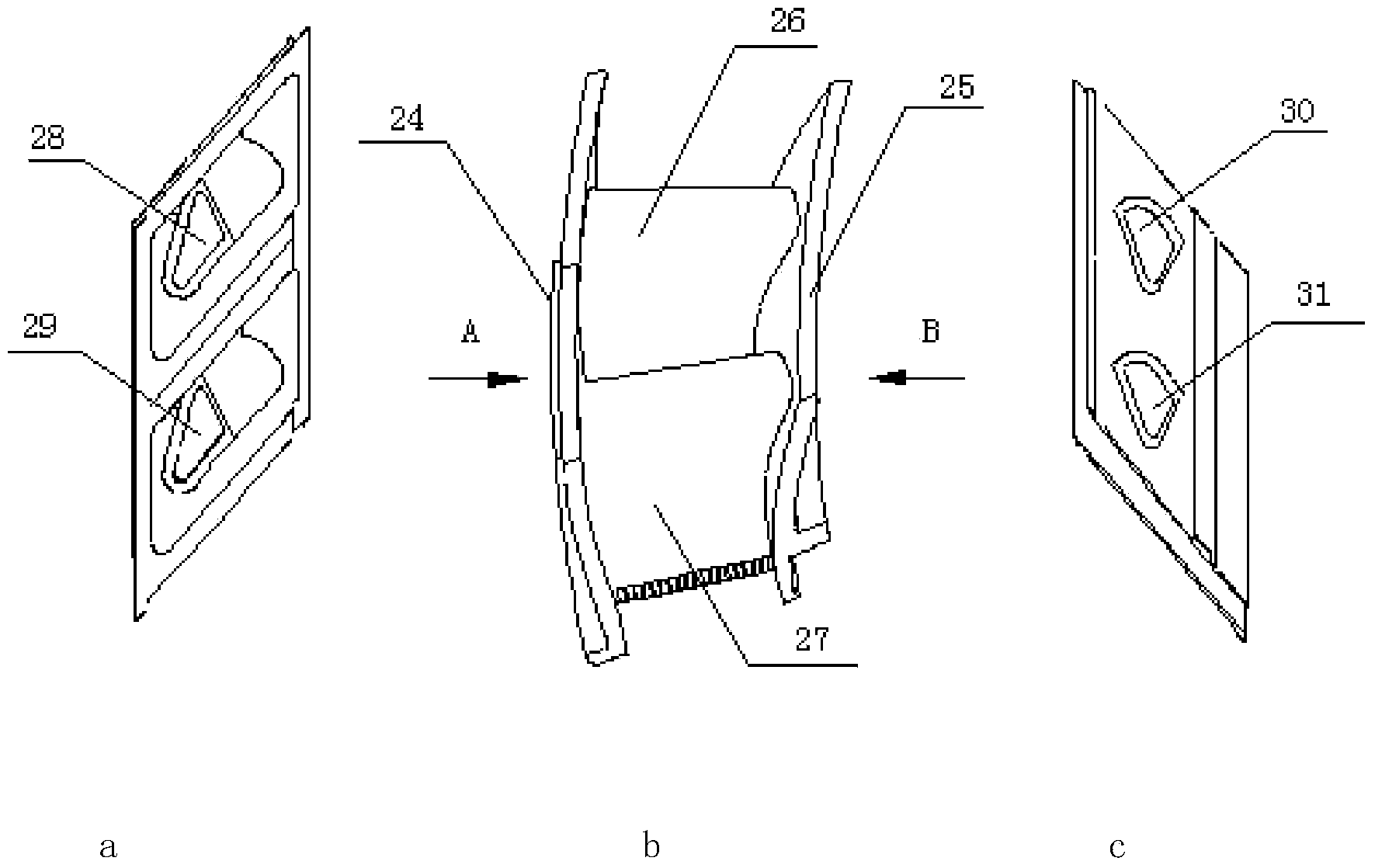

[0044] This embodiment is a guide vane water flow measuring fixture, including a fixture bottom plate 12, a support, a blade lower edge plate gasket 20, a blade upper edge plate gasket 21, a control valve, a water inlet pipeline and a water outlet pipeline.

[0045] The supports include a first support 11 and a second support 14 . The first support 11 and the second support 14 are symmetrically fixed on the upper surface of the jig bottom plate 12 . Both ends of the second water inlet pipeline 16 are respectively connected to the third water inlet hole 42 and the fourth water inlet hole 43 of the holder on the second holder 14 through the adapter 19 . Both ends of the second water inlet pipeline 16 are respectively connected to the fourth control valve 15 and the third control valve 18 through right-angle elbows 23 . There is a second water inlet 17 on the pipeline between the fourth control valve 15 and the third control valve 18 . The blade lower edge plate gasket 20 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com