Rolling linear track grinding process

A linear guide and grinding technology, applied in the field of workpiece grinding, to achieve the effect of reducing production cost, improving work efficiency and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

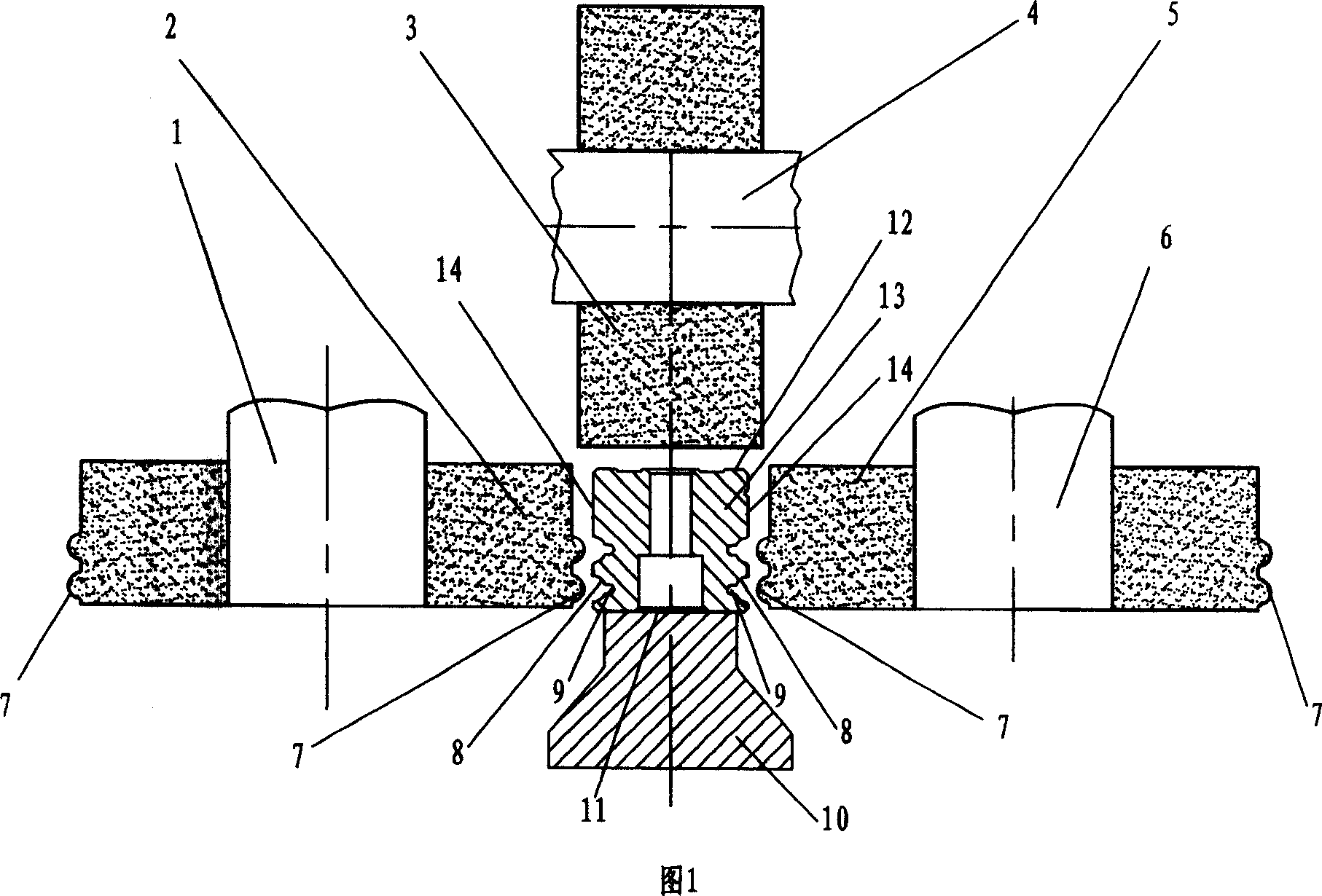

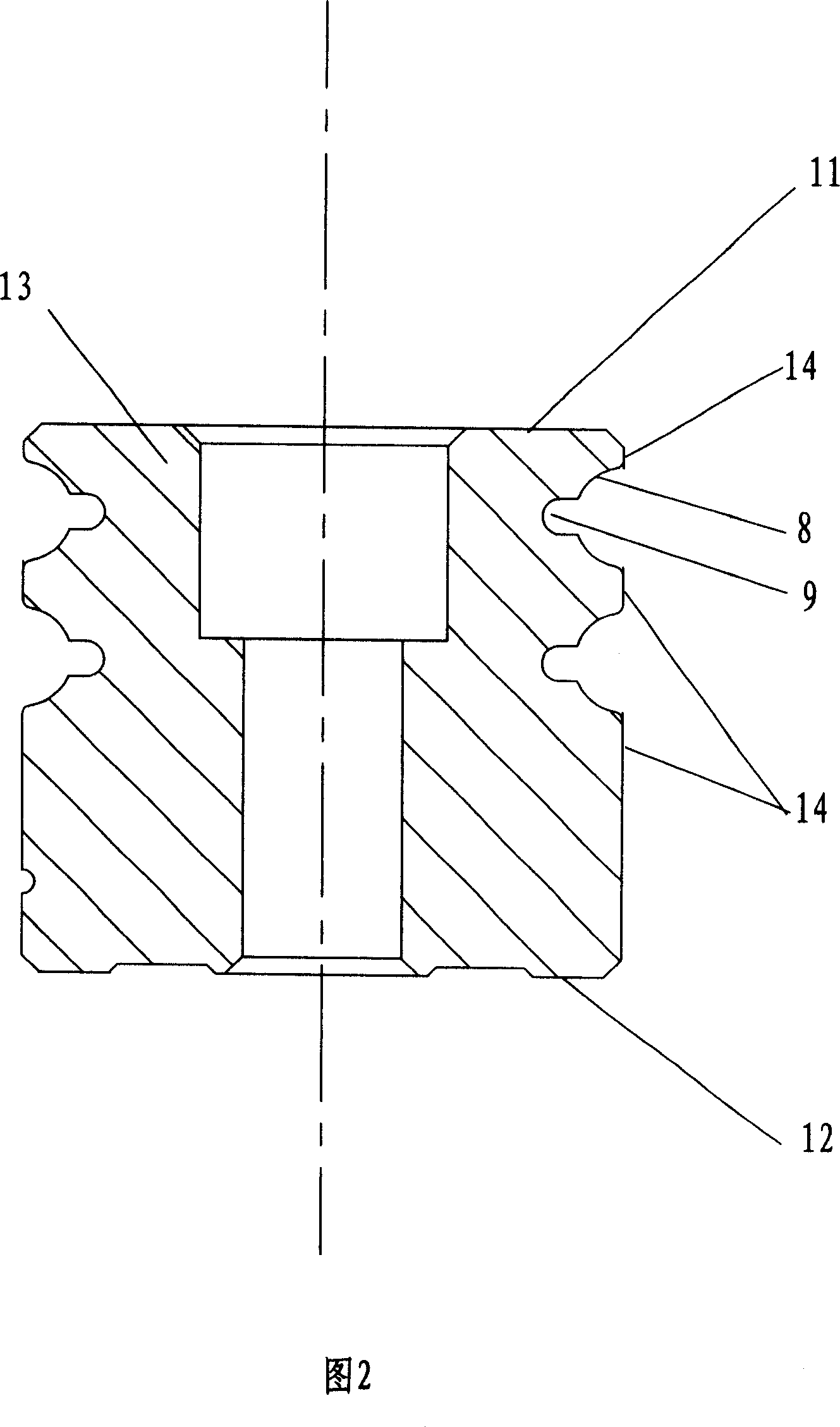

[0013] As shown in Figures 1 and 2: 10 is the magnetic workbench of the three-axis grinding machine, the magnetic force workbench 10 is made to generate magnetic force through the control device, and the linear guide rail 13 is fixed at the same time. The linear guide rail 13 shown in Fig. 2 is its cross-sectional view, 11 Is the top surface of the linear guide, 12 is the bottom of the linear guide, and 14 is the two sides of the linear guide. There are arc-shaped raceway working surfaces 8 on both side surfaces 14 of the linear guide rail, and the bottom of the raceway working surface 8 is processed with a retaining steel wire groove 9 .

[0014] First, machine the top surface 11 of the linear guide rail, the bottom surface 12 of the linear guide rail, the two side surfaces 14, the working surface of the raceway 8, and the retaining wire groove 9, and leave a certain amount of grinding allowance. Generally, the grinding allowance is controlled at 0.3~ between 0.4mm.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com