Steering gear shell body pressing clamp

A steering gear and housing technology, which is applied in the field of press-fitting fixtures, can solve problems such as long time, deformation of the steering gear housing, and low press-fitting efficiency, and achieve the effects of reliable work, reduced clamping times, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

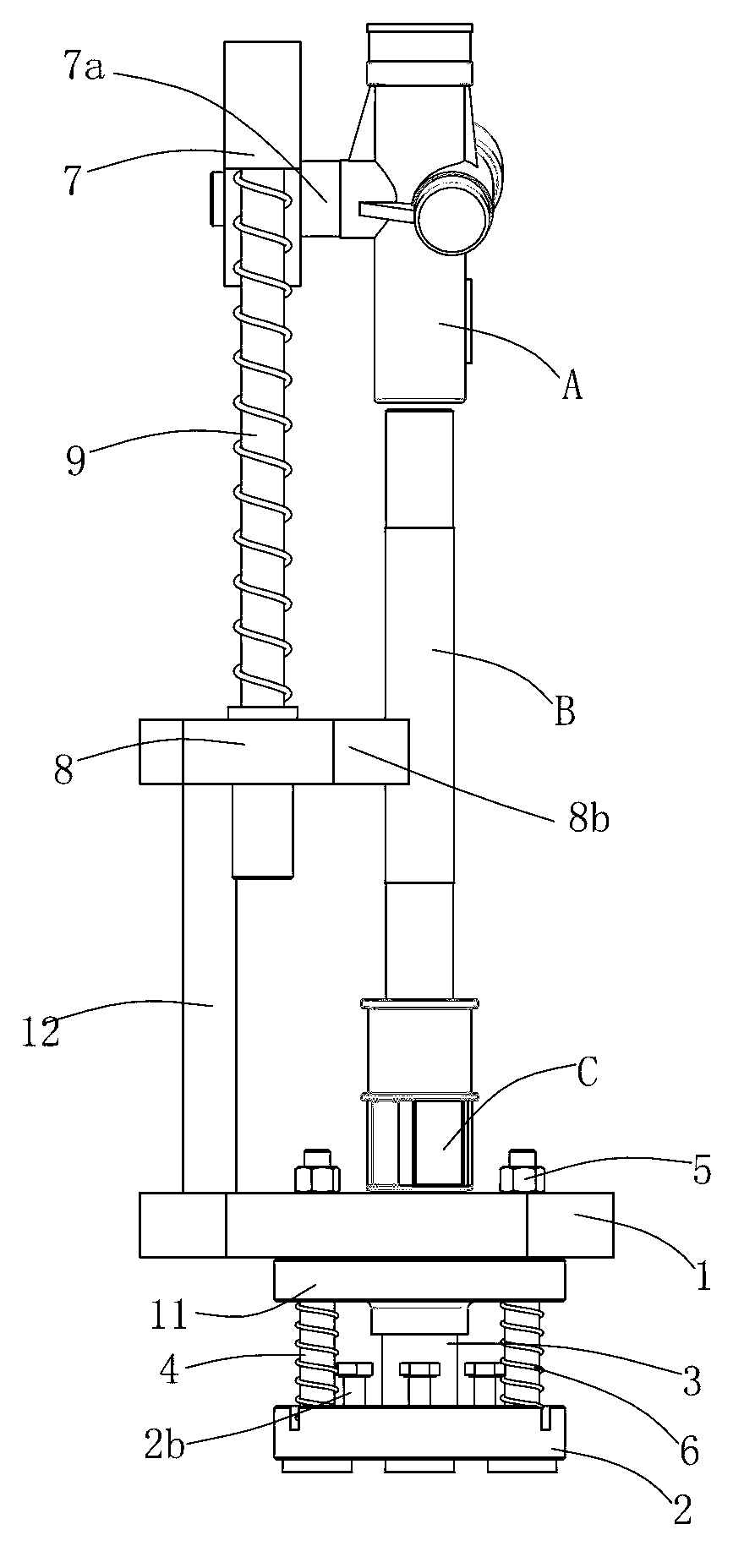

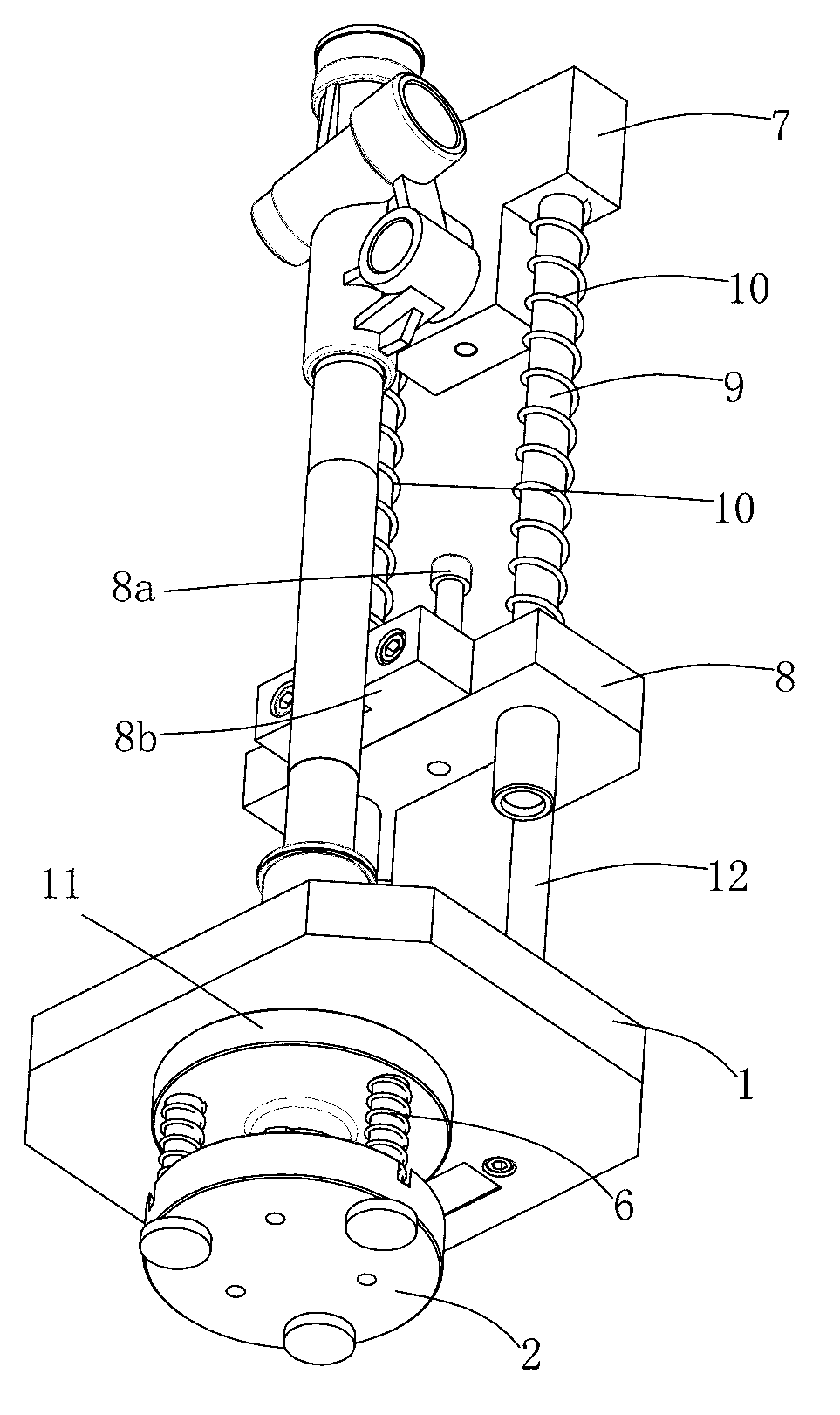

[0014] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

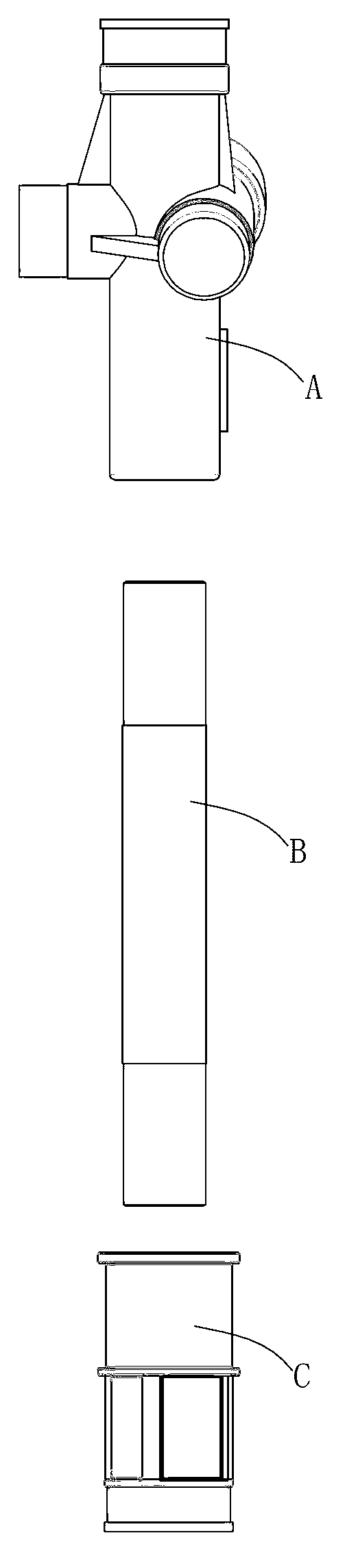

[0015] Such as figure 1 , figure 2 The shown steering gear housing press-fitting jig is composed of a base, a first press-fit mechanism and a second press-fit mechanism arranged on the base.

[0016] The base is made up of upper deck 1, lower deck 2, guide rod 3, screw rod 4 and nut 5. The screw rod 4 and the nut 5 are arranged correspondingly to form a set of fastening structures. The upper and lower decks 1 and 2 are arranged at intervals and are fastened into one body by screw rods 4 and nuts 5 . There are three screw rods 4 and three nuts 5 arranged between the upper deck 1 and the lower deck 2. After forming the fastening structure, it is better to be evenly distributed on the base in a circle. The number of screw rods 4 and nuts 5 is not limited to three, according to Setup is required. The lower end of the guide rod 3 is fixed on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com