Integral leaf disk grinding and polishing processing and measuring integration device

A blisk, grinding and polishing technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problem of low automation of blisk grinding and polishing, disconnection between grinding and polishing processing and measurement, and consistent quality Difficult to guarantee and other problems, to achieve the effect of reducing the number of positioning and clamping, novel structure, and improving processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

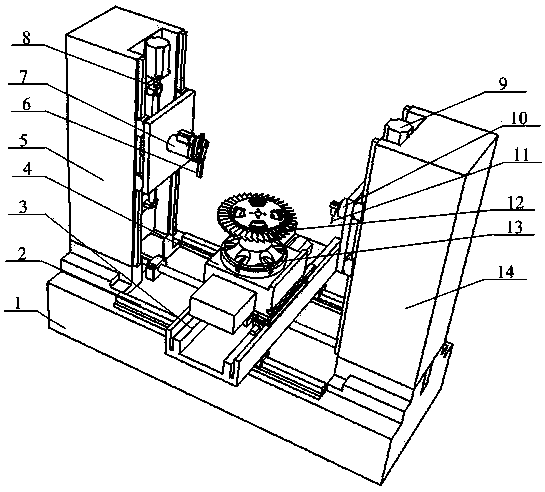

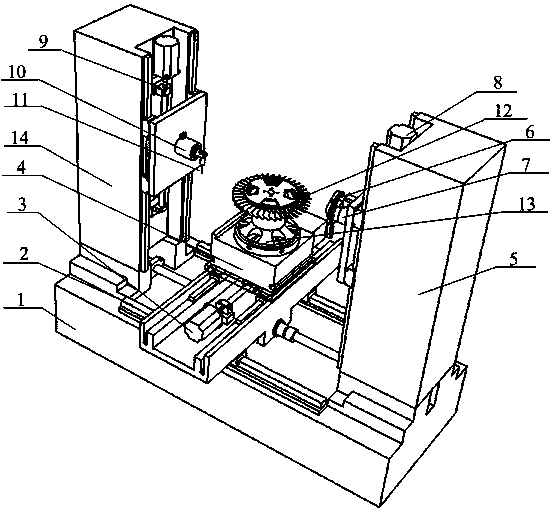

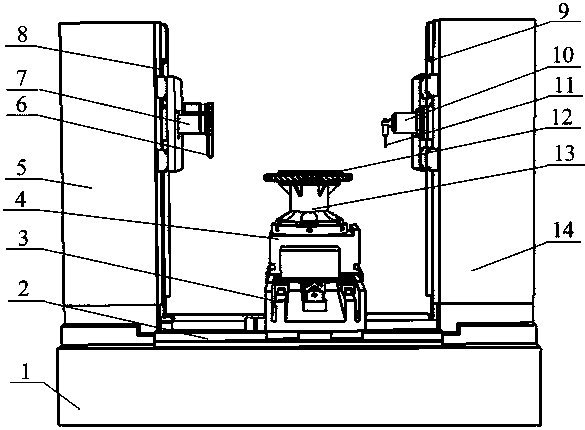

[0016] The Y-axis servo drive unit 2, column 1 5 and column 2 14 are respectively fixedly connected with the bed 1, and the Z-axis servo drive unit 1 8 is installed on the column 1 , and the B-axis rotation unit 8 is installed on the Z-axis servo drive unit 1 . Drive unit one 7, the grinding and polishing tool system 6 is installed on the B-axis rotary drive unit one 7; the Z-axis servo drive unit two 9 is installed on the column two 14, and the B-axis rotary drive unit is installed on the Z-axis servo drive unit two 9 Two 10, the contact measuring device or non-contact measuring device 11 is installed on the B-axis rotary drive unit 10; the Y-axis servo drive unit 2 is equipped with the X-axis servo drive unit 3, and the X-axis servo drive unit 3 is installed with The C-axis rotation drive unit 4 is equipped with a special fixture 13 on the C-axis rotation drive unit 4 , and the whole blisk 12 is installed on the special fixture 13 .

[0017] Grinding and polishing tool syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com