Fixture and method for processing half-shaft casing holes at both ends of rear axle housing in vehicle

A technology of half shaft casing and rear axle housing, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

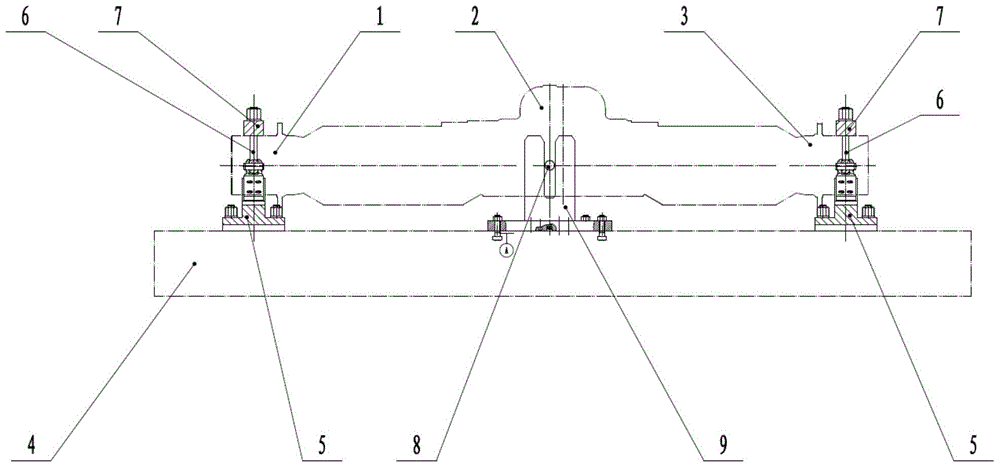

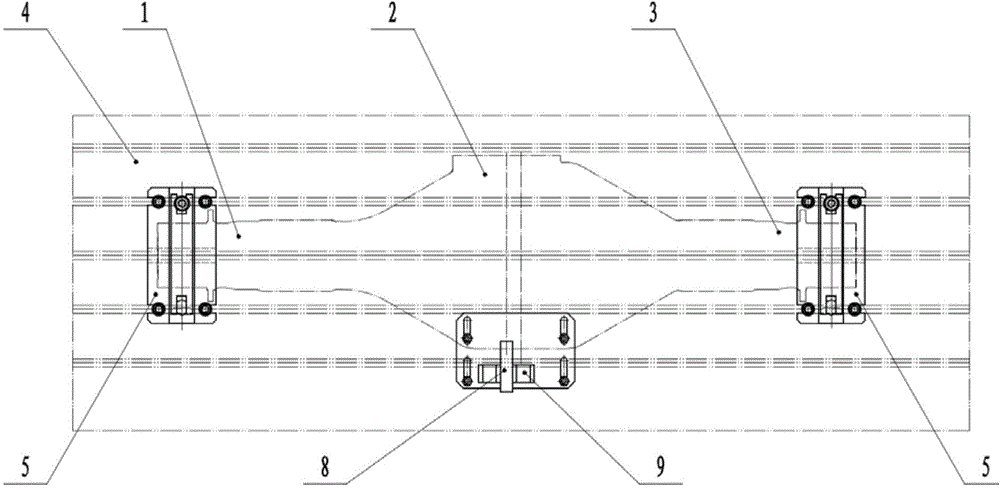

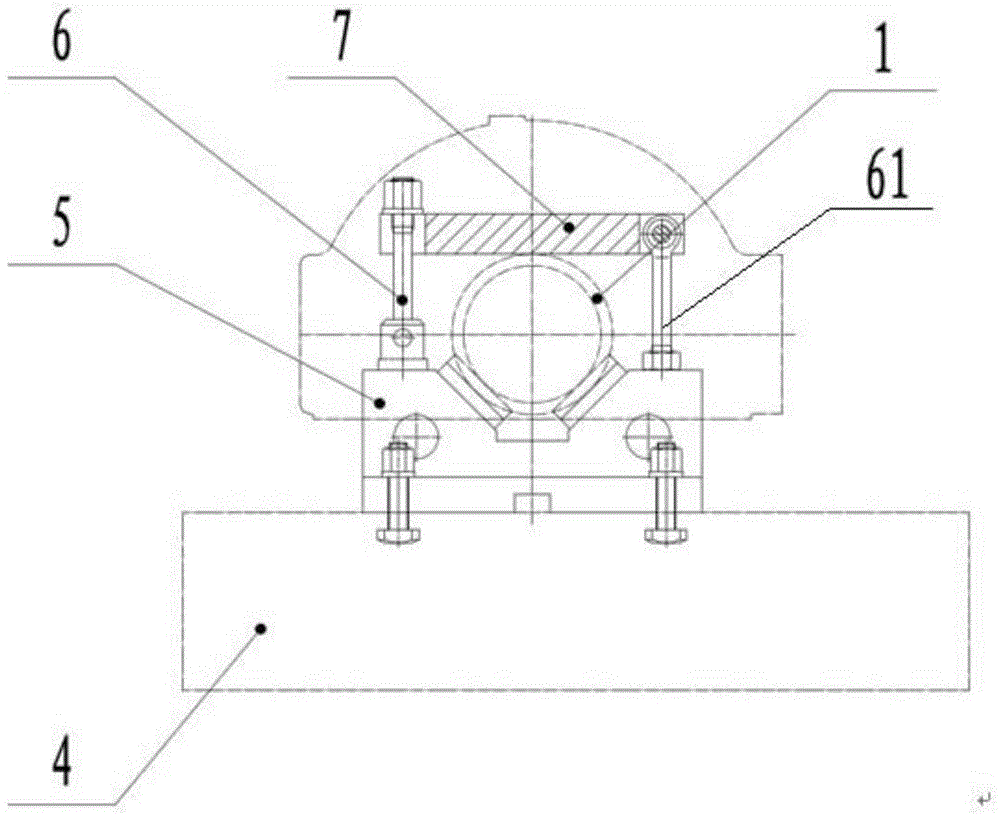

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1 to Figure 6 , a processing fixture for half-shaft casing holes at both ends of the rear axle housing in an automobile, comprising a workbench 4, a V-shaped seat 5 is respectively provided at both ends of the workbench, and a V-shaped seat 5 is provided on one side of each V-shaped seat. First column 6 is arranged, and the upper end of this first column is provided with thread, and cooperates with a nut; One end of the workbench is hinged, and the other end of the workpiece pressing plate is provided with a transverse notch, and the transverse notch is correspondingly matched with the upper part of the first column; a limit seat 9 is provided in the middle of the workbench, and the limit seat is set There is a vertical notch so that the positioning threaded pin 8 passes through. The V-shaped seat 5 is connected to the workbench 4 through threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com