Fixture for drilling inflating and discharging holes in hub

A technology of air vents and hubs is applied in the field of heavy-duty axle wheel hub processing fixtures, which can solve the problems of increasing productivity, high labor intensity, and low efficiency, reducing the number of clamping times and improving labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

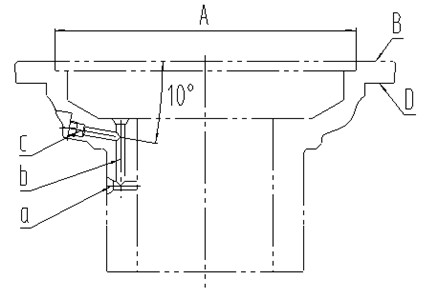

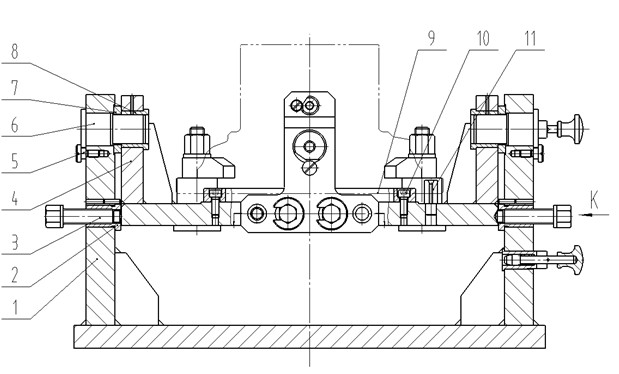

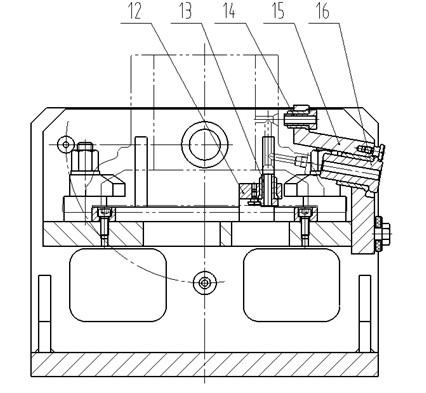

[0027] see Figure 2-Figure 11 , the heavy-duty axle hub drilling fixture mainly consists of a main body 1, a rotating body 4, a rotating shaft 6, a compression screw 3, a positioning ring 9, a positioning pin 11, a drilling template 15, a b drilling template 12, a hook-shaped pressing plate 18, Locator 19 etc. are formed.

[0028] see figure 2 , The revolving body 4 is a U-shaped frame body, its two sides and the body 1 are connected through the rotating shaft 6 and the adjusting washer, and the gap between the two is adjusted with the adjusting washer 7 to ensure that the revolving body 4 rotates flexibly around the rotating shaft 6. First screw 5 is housed beside rotating shaft 6, is pressed on rotating shaft 6 limits, prevents rotating shaft 6 from deviating from. On one side of the revolving body 4, with the revolving shaft 6 as the center, there are x positioning holes and y positioning holes on the circumferences of the radii R1 and R2, the radius R1 is 180mm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com