Flange end plate all-in-one machine with drilling, tapping and groove milling functions

An all-in-one machine and drilling mechanism technology, used in metal processing machinery parts, clamping, support and other directions, can solve the problem that the flange end plate cannot be milled into strip grooves, the flange end plate processing technology is complex, and the workpiece milling cannot be completed. The groove process and other problems can achieve the effect of small vibration, reduction of clamping times and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

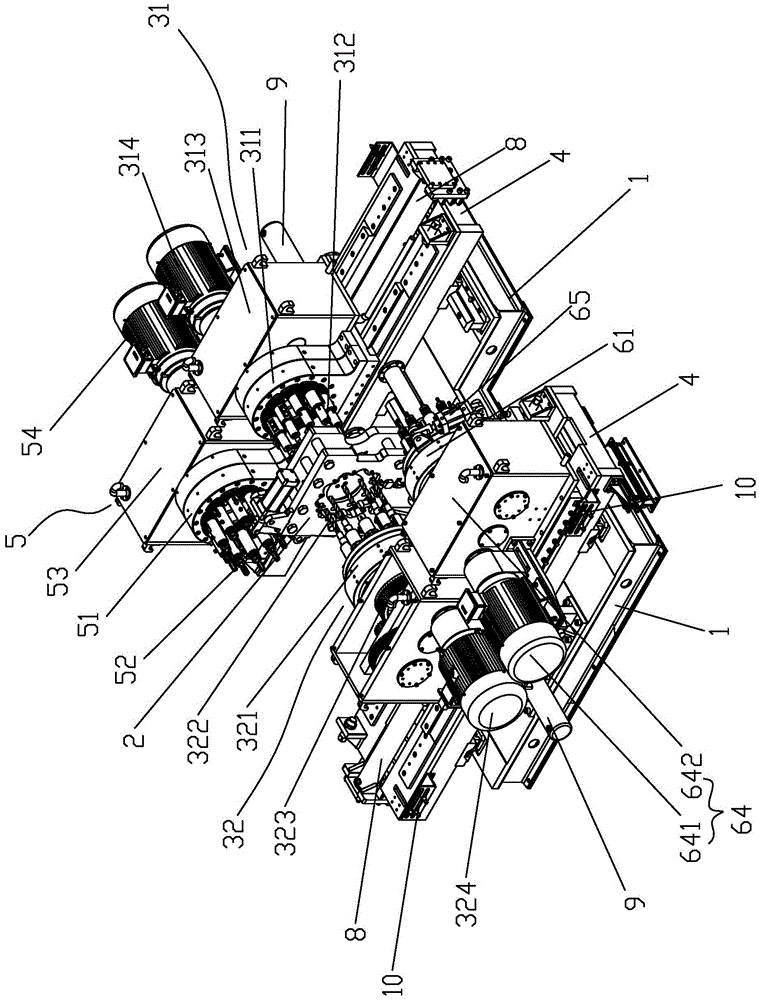

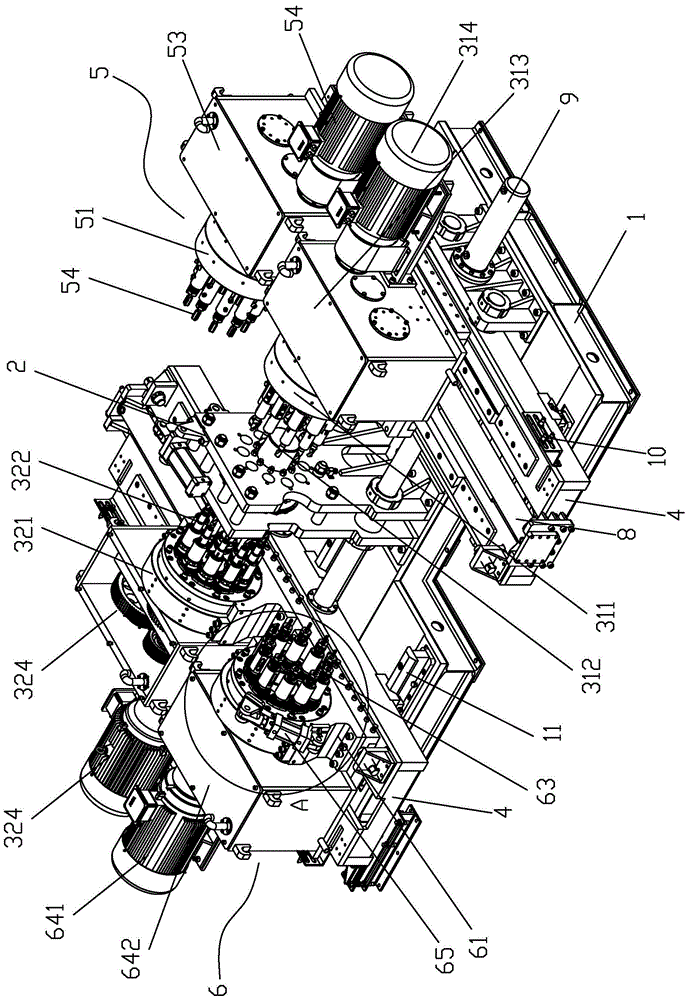

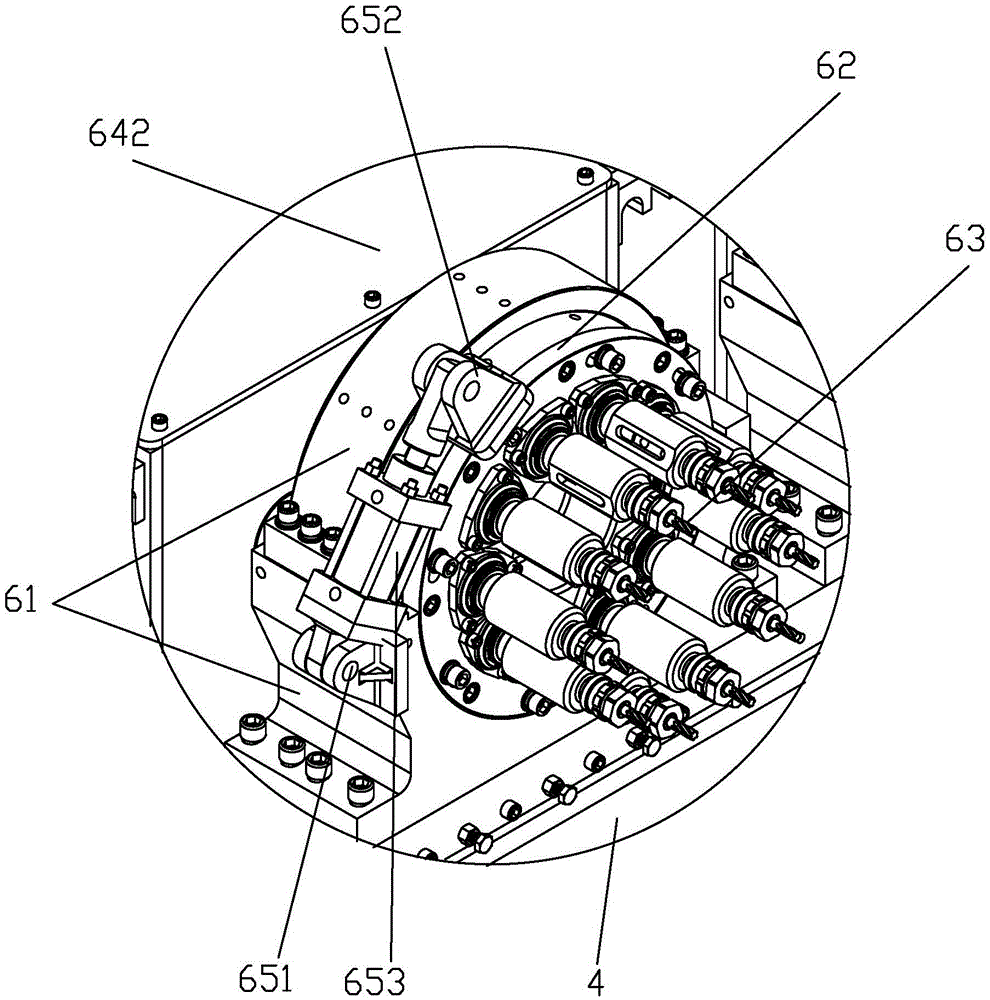

[0027] An integrated machine for drilling, tapping and milling flange end plates, comprising a base 1, on which a clamping mechanism 2 for clamping a flange end plate 100 is provided, and in the clamping mechanism The two sides of 2 are provided with a drilling mechanism 3 that can move toward each other to drill holes in the flange end plate 100 inside, and the two sides of the clamping mechanism 2 are also provided with a movable table 4 that can move laterally relative to the base 1, so The above-mentioned drilling mechanism 3 is arranged on the movable platform 4, and the described movable platform 4 is also provided with tapping and milling grooves for the inner flange end plate 100 as it moves toward the clamping mechanism 2. Mechanism 5 and groove milling mechanism 6, described movable table 4 is also provided with longitudinal slide rail 7, and described drilling me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com