Vertical five axle interlocked gantry digital control milling machining center

A five-axis linkage, machining center technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of single machine tool processing methods and inconspicuous processing equipment, and achieve convenient equipment maintenance, improved surface accuracy, and increased cutting force The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

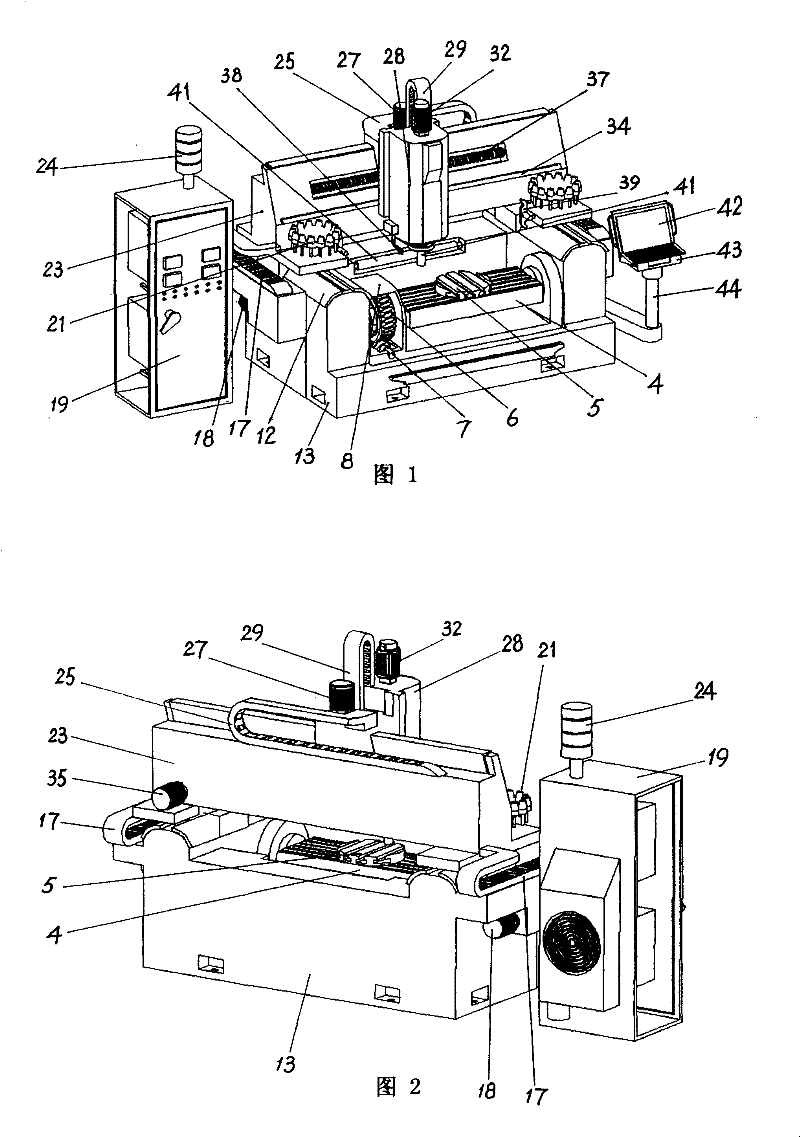

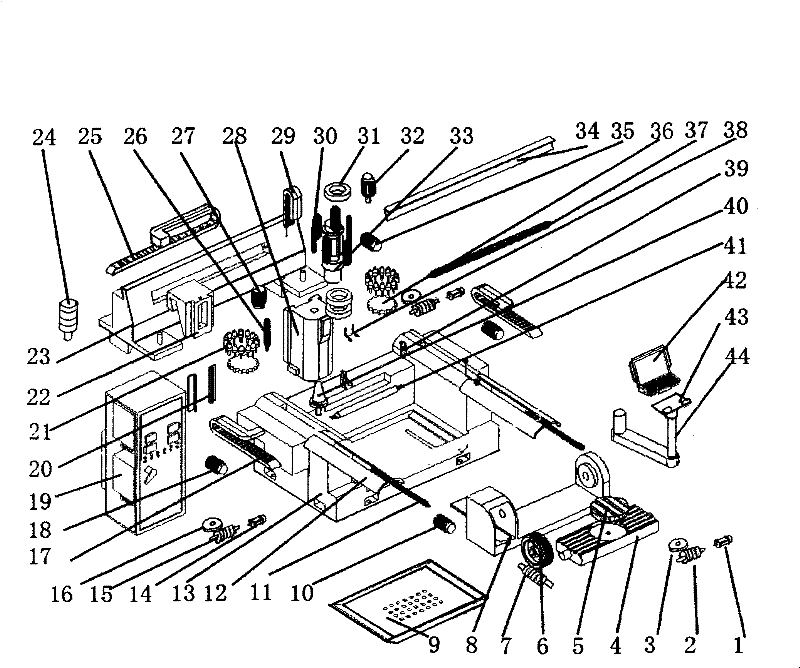

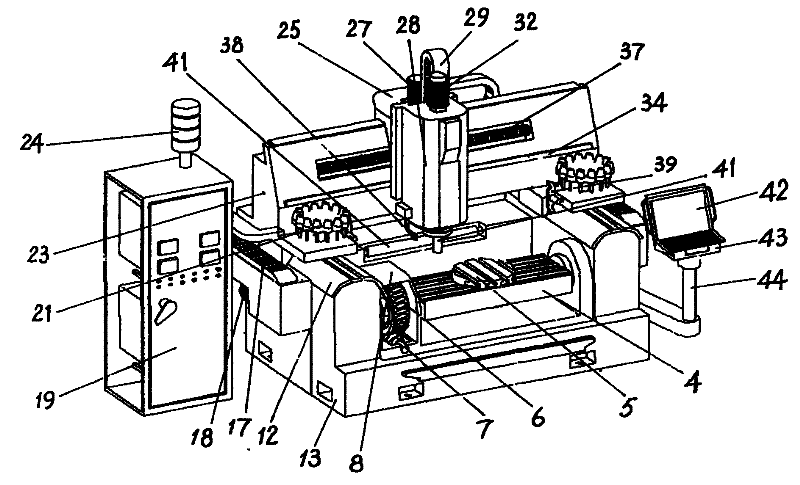

[0056] The specific implementation manner of the gantry vertical five-axis linkage CNC milling and milling machining center of the present invention is given below in conjunction with the accompanying drawings.

[0057] See attached figure 1 And attached image 3 .

[0058]A gantry vertical five-axis linkage CNC grinding and milling machining center, comprising a bed body 13, a gantry frame 23, a rotary table frame 8, an electrical control box 19, a tool 21, a spindle box 28, an operation panel 42, and a rotary table, The X-axis transmission screw 11, the Y-axis transmission screw 37, the Z-axis transmission screw 26 and the rotary tool magazine 36; Connection, machine tool control circuit modules such as computer, PLC circuit, instrument panel, overload protection circuit are arranged inside the electric control box 19, and the work indicator light 24 can be set on the top of the electric control box 19, in order to show the working status of the milling processing center; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com