Fixture

A technology of fixtures and guide rails, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of low production efficiency, achieve the effects of improving production efficiency, reducing the number of clamping times, and being easy to use on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

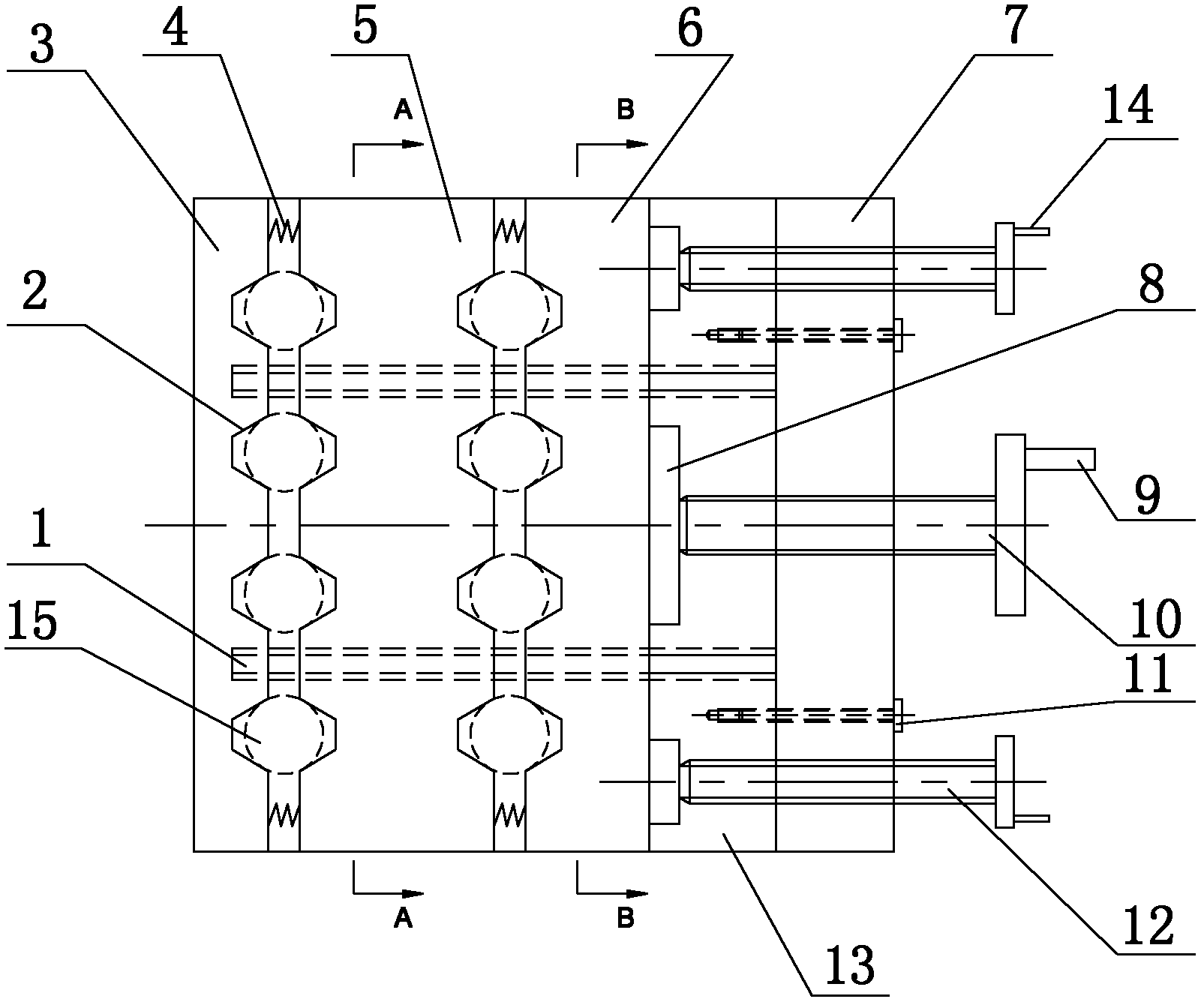

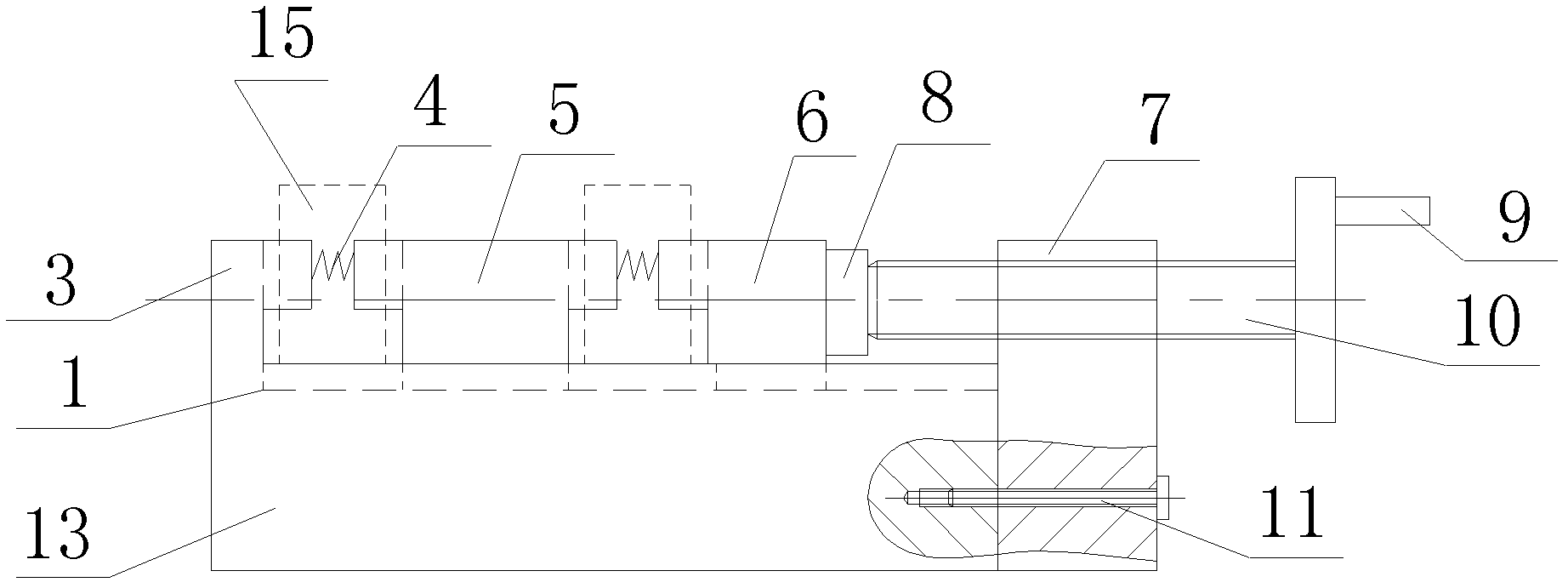

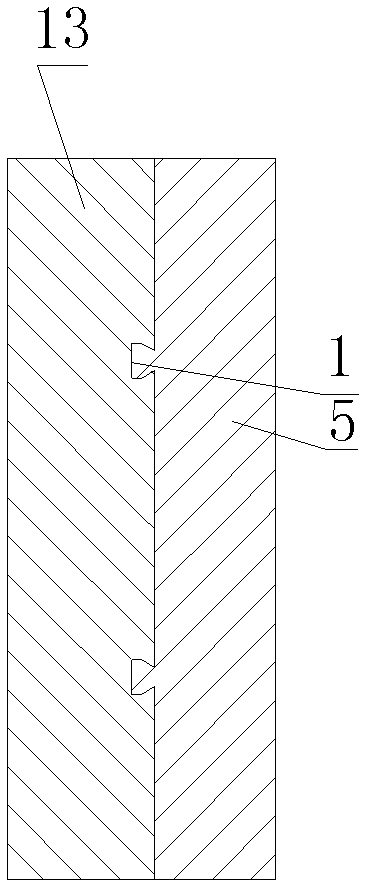

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] see Figure 1-Figure 4 One end of the upper surface of the base 13 is fixedly provided with a fixed pressing block 3, and one end of the guide rail 1 is vertically connected with the fixed pressing block 3, and there is a sliding pressing block that can slide along the guide rail 1 on the guide rail 1. The guide rail 1 can be any structure that can make the sliding pressing block move along a straight track, such as a dovetail groove. At least two guide rails 1 are approximately symmetrical with the longitudinal centerline of the sliding pressing block as the axis, so as to ensure the stable sliding of the sliding pressing block. The sliding briquetting block is parallel to the fixed briquetting block 3, the sliding briquetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com