Full-automatic numerical control screw tap thread grinder

A thread grinding machine, fully automatic technology, applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problem of affecting the dressing quality of tap relief grinding wheels, low dressing accuracy of tap relief grinding wheels, and machine tools. Accurate reduction and other problems, to achieve the effect of improving the accuracy of measurement and feeding, reducing the number of clamping times, and reducing the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

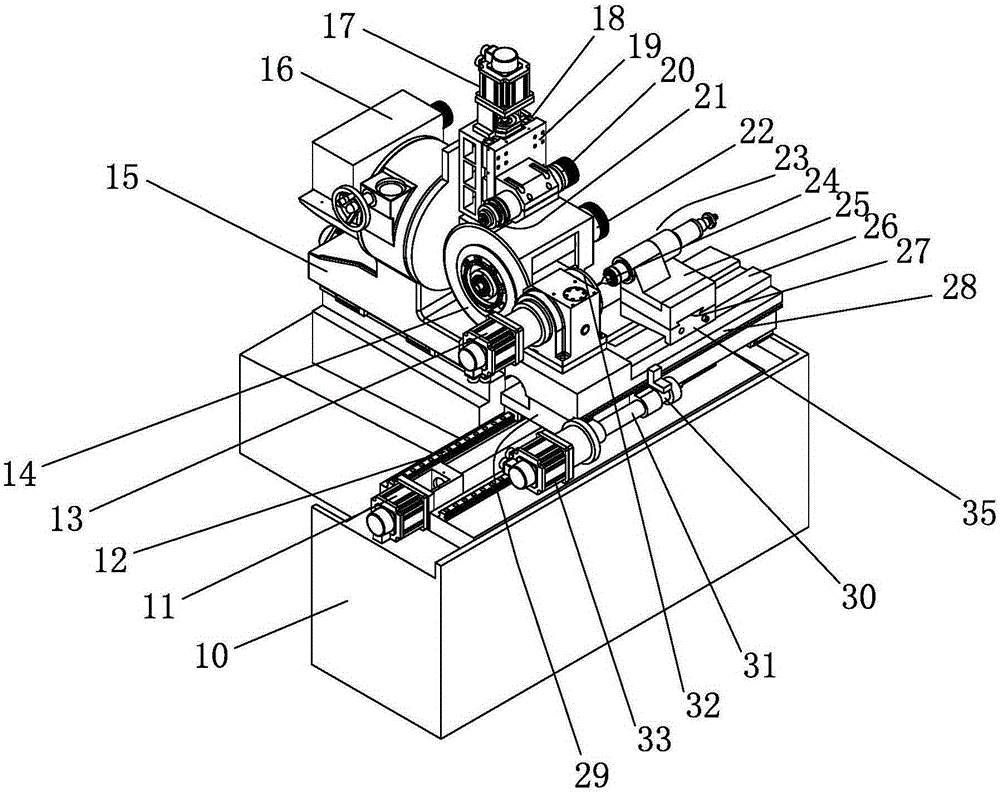

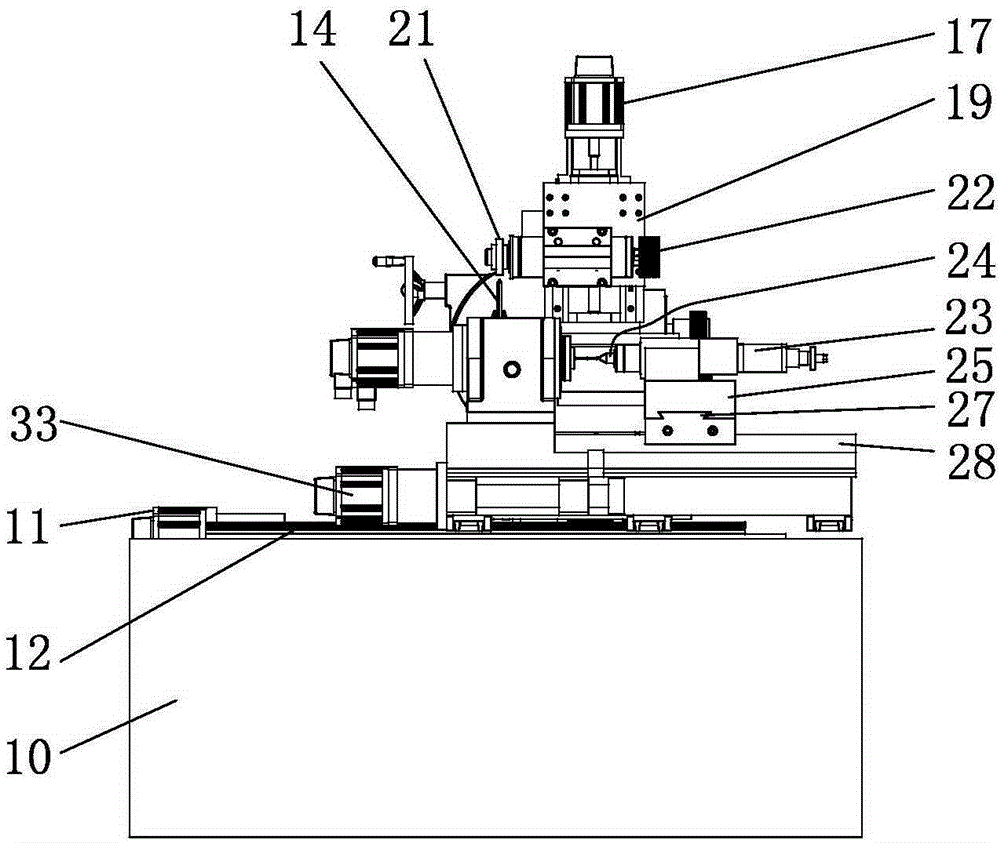

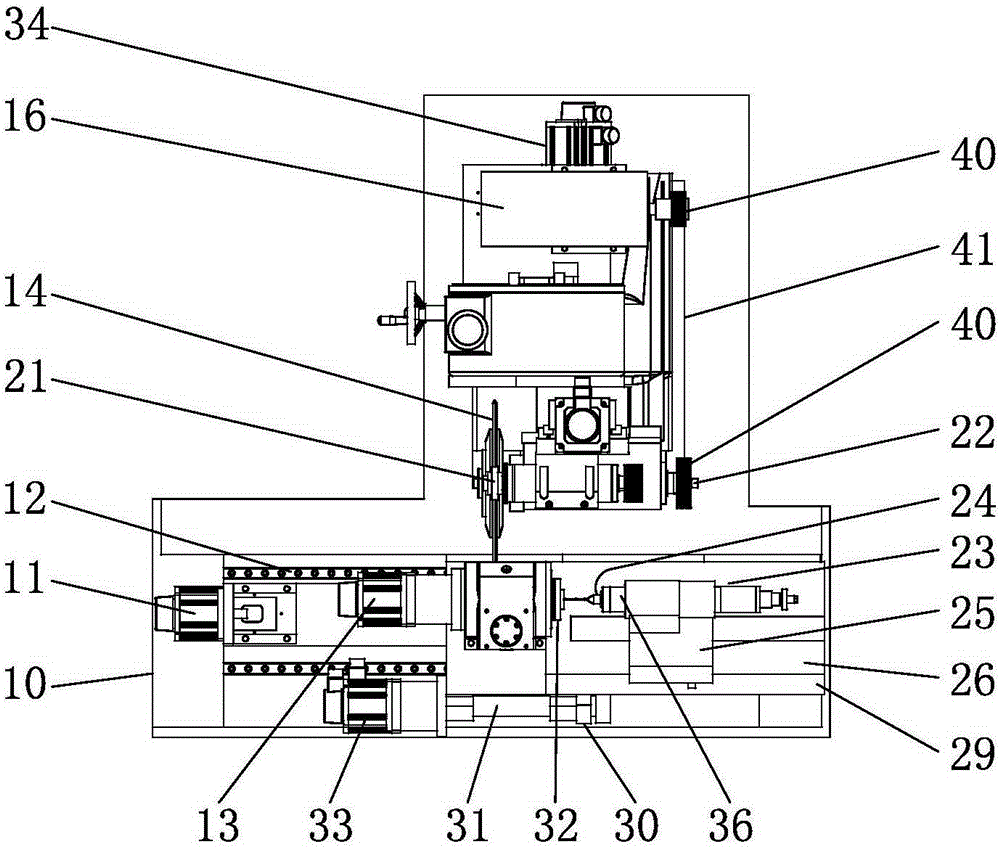

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — image 3 :

[0025] A fully automatic CNC tap thread grinding machine, including a grinding machine base 10, a rear supporting plate 15 driven by a power device to move along the longitudinal sliding rail on the longitudinal slide rail provided on the rear side of the grinding machine base 10 workbench, and the front side of the rear supporting plate 15 is provided There is the grinding wheel shaft 22 driven by the power unit to rotate, and the tap shoveling grinding wheel 14 is installed on the grinding wheel shaft 22, and the vertical slide rail 18 provided on the back supporting plate 15 of the grinding wheel shaft 22 rear side is provided with a power unit driving along the vertical slide The slide block 19 that rail 18 moves, and the diamond rotating shaft 20 (the diamond rotating shaft 20 can also use electric spindle to simplif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com