Axle radial ultrasonic automatic flaw detecting device and control method

A flaw detection device, ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as inconvenient operation, high labor intensity, and complex device structures. Achieve the effects of improving work efficiency, reducing labor intensity, and low control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The content of the specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

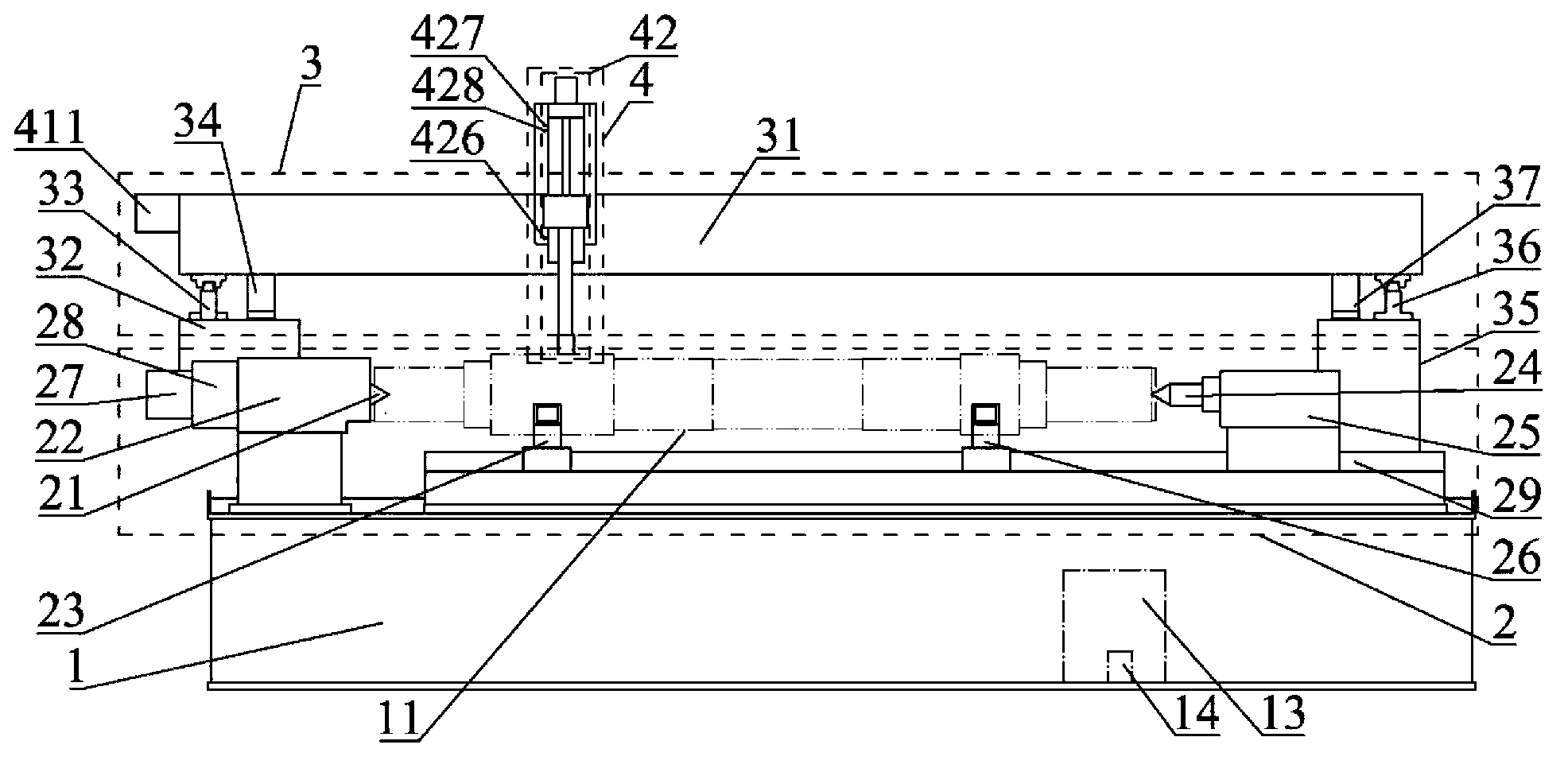

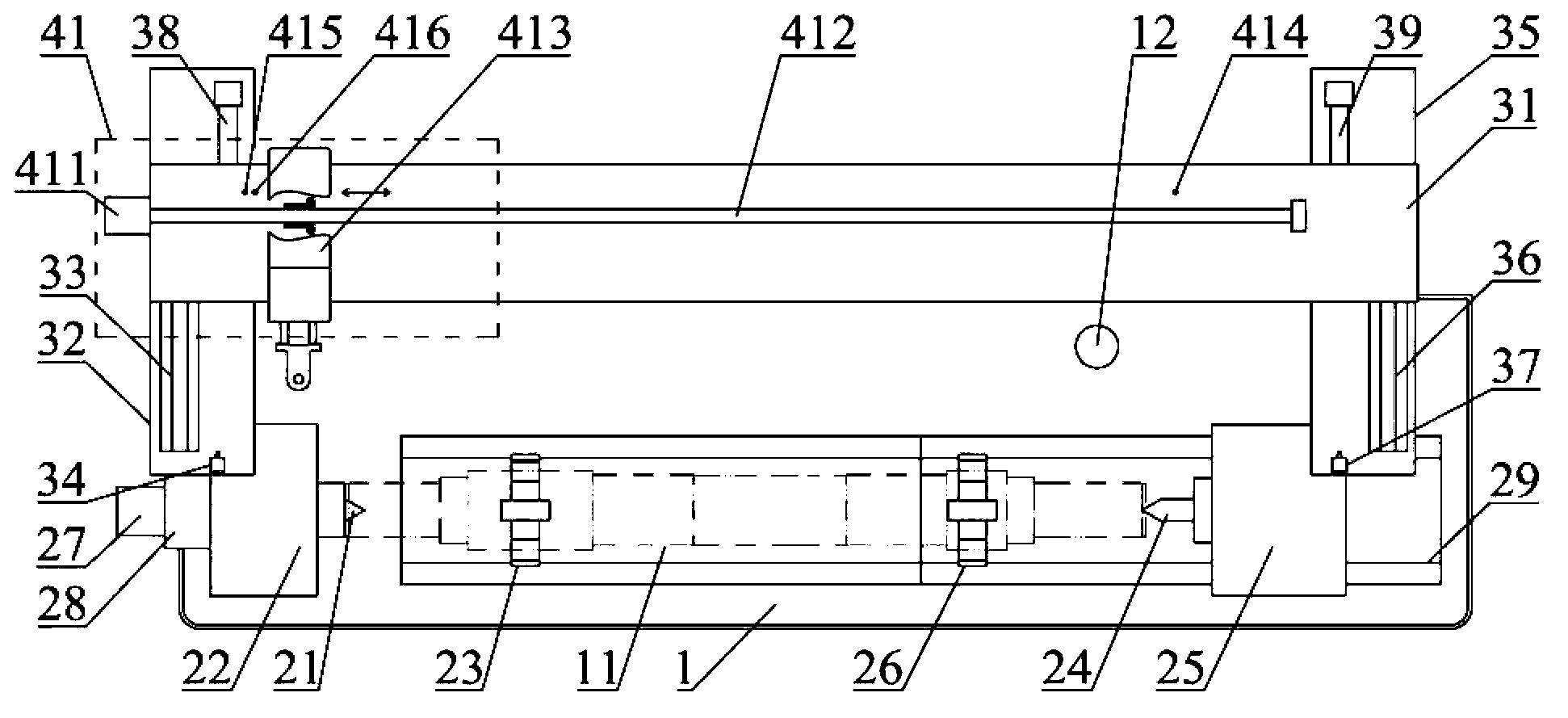

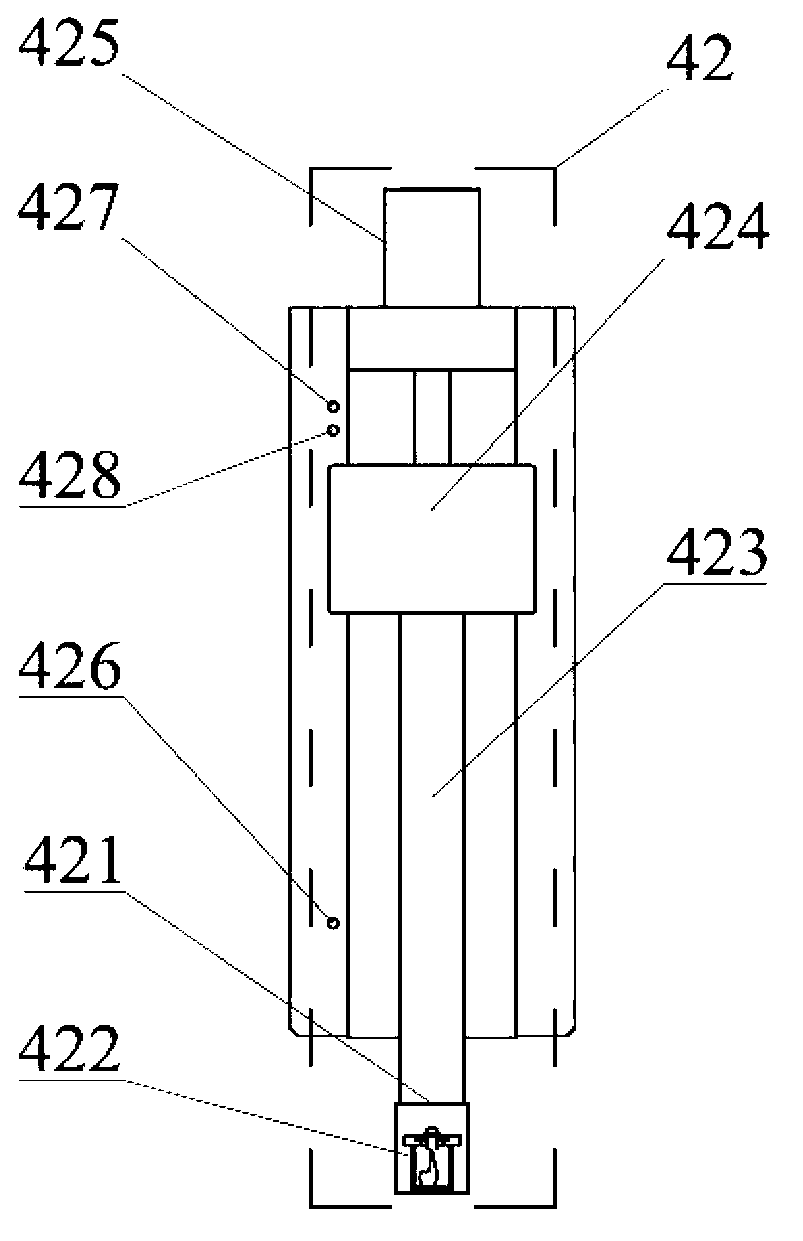

[0066] The axial radial ultrasonic automatic flaw detection device of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4As shown, it includes a bed 1, an axle rotation support unit 2, a gantry unit 3, a flaw detection unit 4, an ultrasonic generator receiver 5, a motor driver unit 6, a control unit 7 and an interactive operation unit 8; the bed 1 A coupling fluid collection port 12 is provided on the bed, and a coupling fluid storage tank 13 and a circulation pump 14 are fixed inside the bed 1, and the circulation pump 14 and the coupling fluid storage tank 13 are connected by a hose; the axle rotation support unit 2 is fixed On the bed 1, the axle rotation supporting unit 2 includes a first pneumatic center 21 and a second pneumatic center 24; Rail 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com