Automatic loading robot for packing boxes

A technology of robots and packaging boxes, applied in the field of machinery, can solve the problems of fragile packaging boxes, low work efficiency, and large space occupation, and achieve the effects of saving space, improving efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

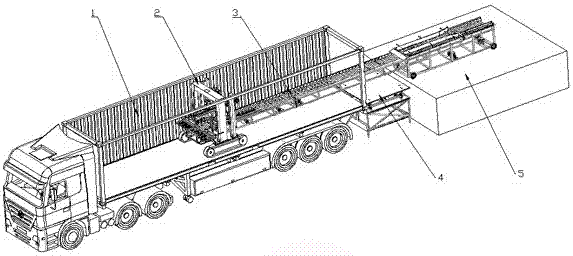

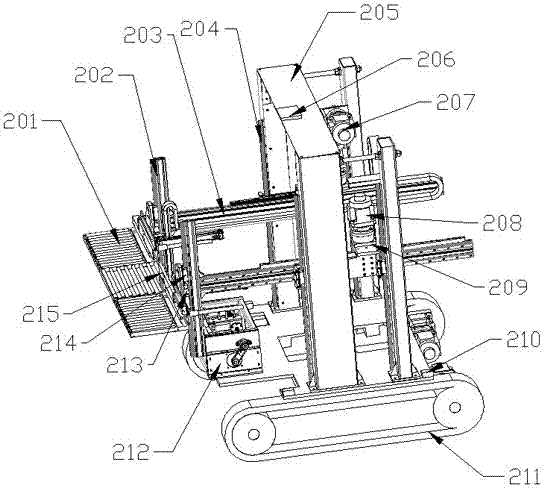

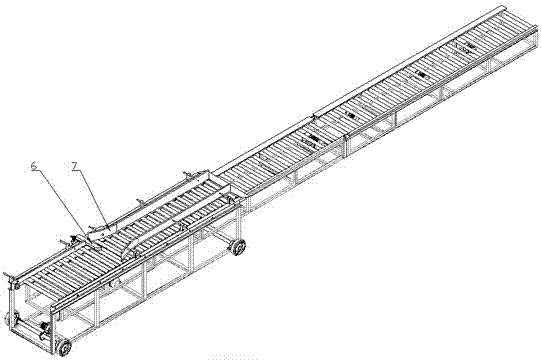

[0021] In order to better understand and implement, the present invention will be further described below in conjunction with accompanying drawing: packing case automatic loading robot, comprise PLC automatic control system, packing palletizing trolley 2 and telescopic transport line 3, telescopic transport line 3 is provided with a reversing device 6 and a straightening device 7. The packing and palletizing trolley 2 includes a gantry 205, the lower end of the gantry 205 is provided with a crawler-type walking device 211, and the front ends of both sides of the gantry 205 are fixedly connected to the large Z-axis 204 A laser rangefinder 210 on both sides is respectively provided at the four corners of the crawler-type walking device 211, and a front-end laser rangefinder 206 is fixed on the upper end of the gantry 205;

[0022] The big Z-axis 204 is connected with the X-axis 203, the front end of the X-axis 203 is provided with a small Z-axis 202, a lifting device 207 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com