Drop test device for movable impact platform

A test device and platform technology, applied in the direction of measurement device, impact test, machine/structural component test, etc., can solve problems such as affecting the real reference of the test, temperature increase, small wheel rotational inertia, etc., to avoid the wheel Elevated temperature, guaranteed authenticity, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Here, the present invention will be described in further detail in conjunction with the accompanying drawings.

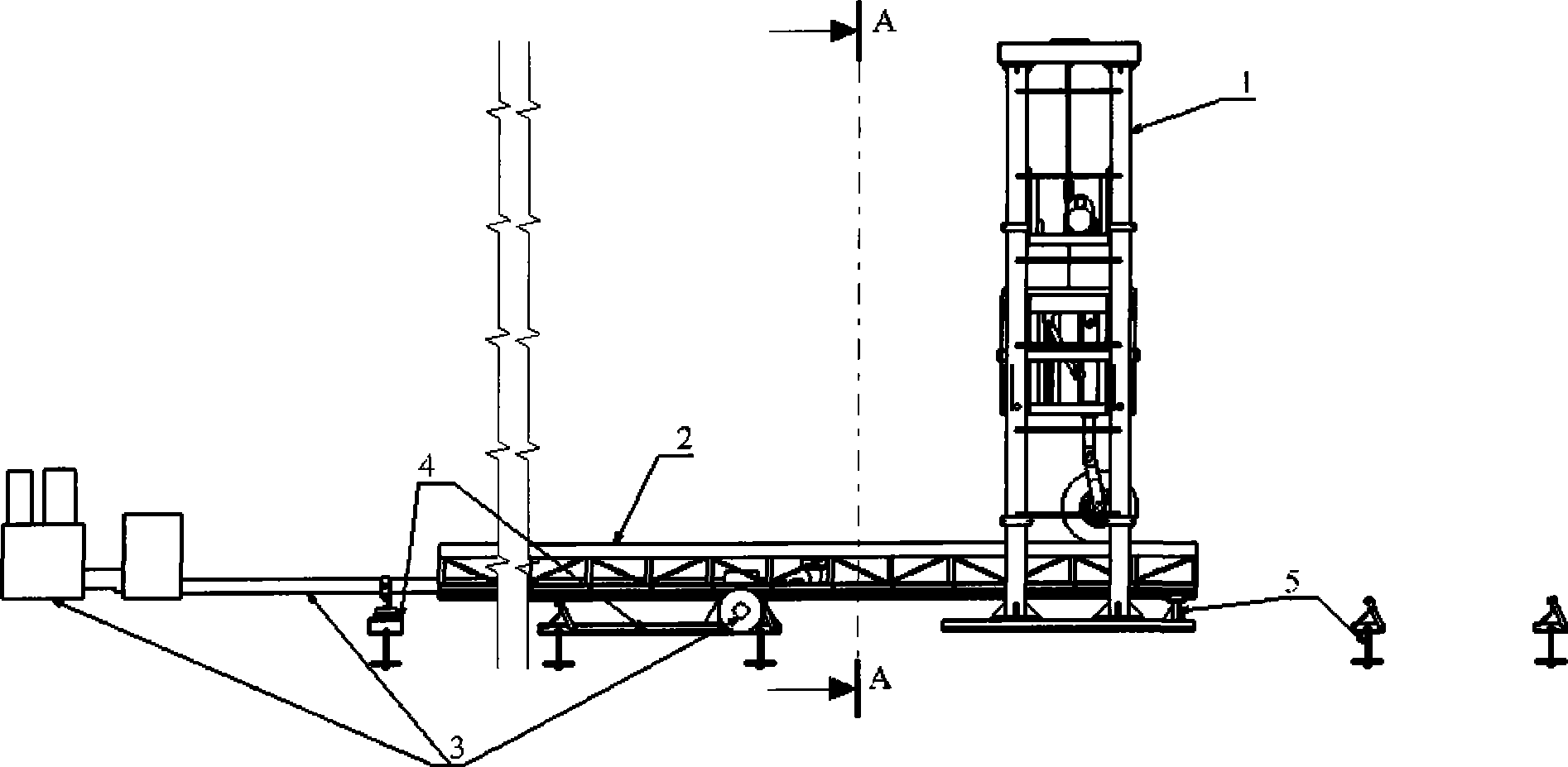

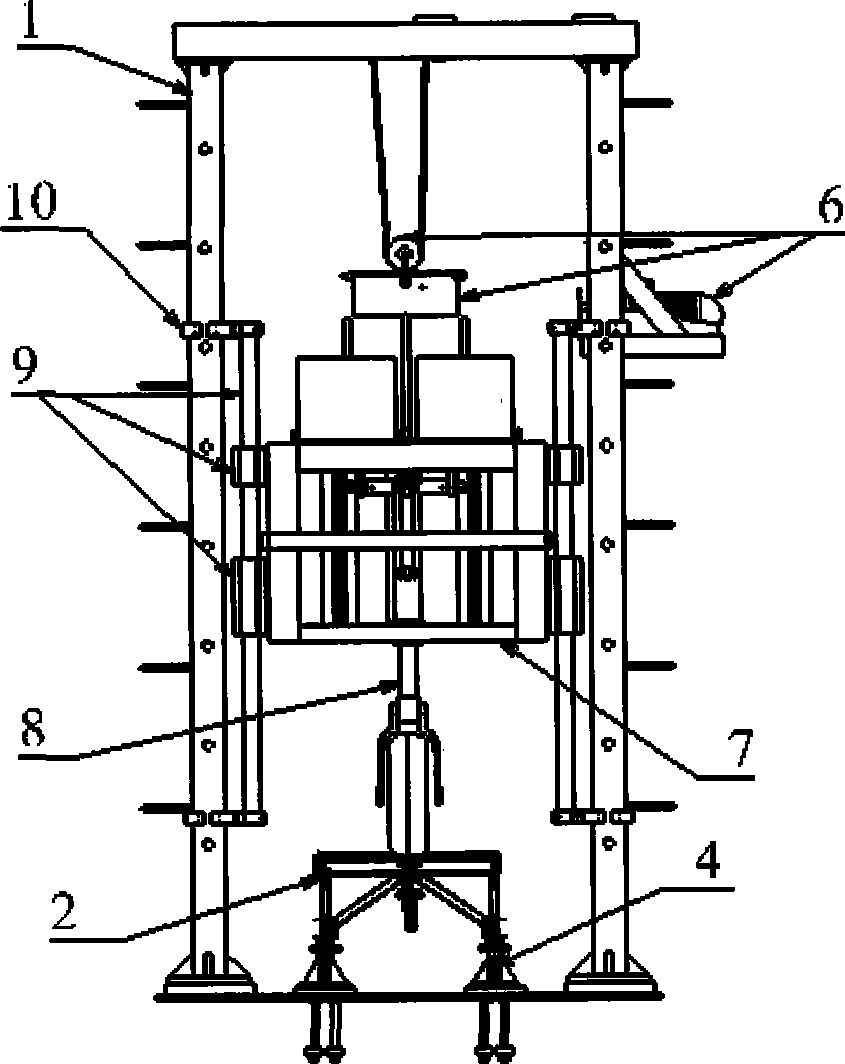

[0028] The invention provides a drop shock test device for a movable impact platform, which mainly consists of a gantry 1, a movable impact platform 2, a hydraulic drive system 3, a ground guiding mechanism 4, a ground fixing mechanism 5, a retractable mechanism 6, and a hanging basket 7 , Undercarriage 8, hanging basket guiding mechanism 9 and gap adjusting mechanism 10 are formed.

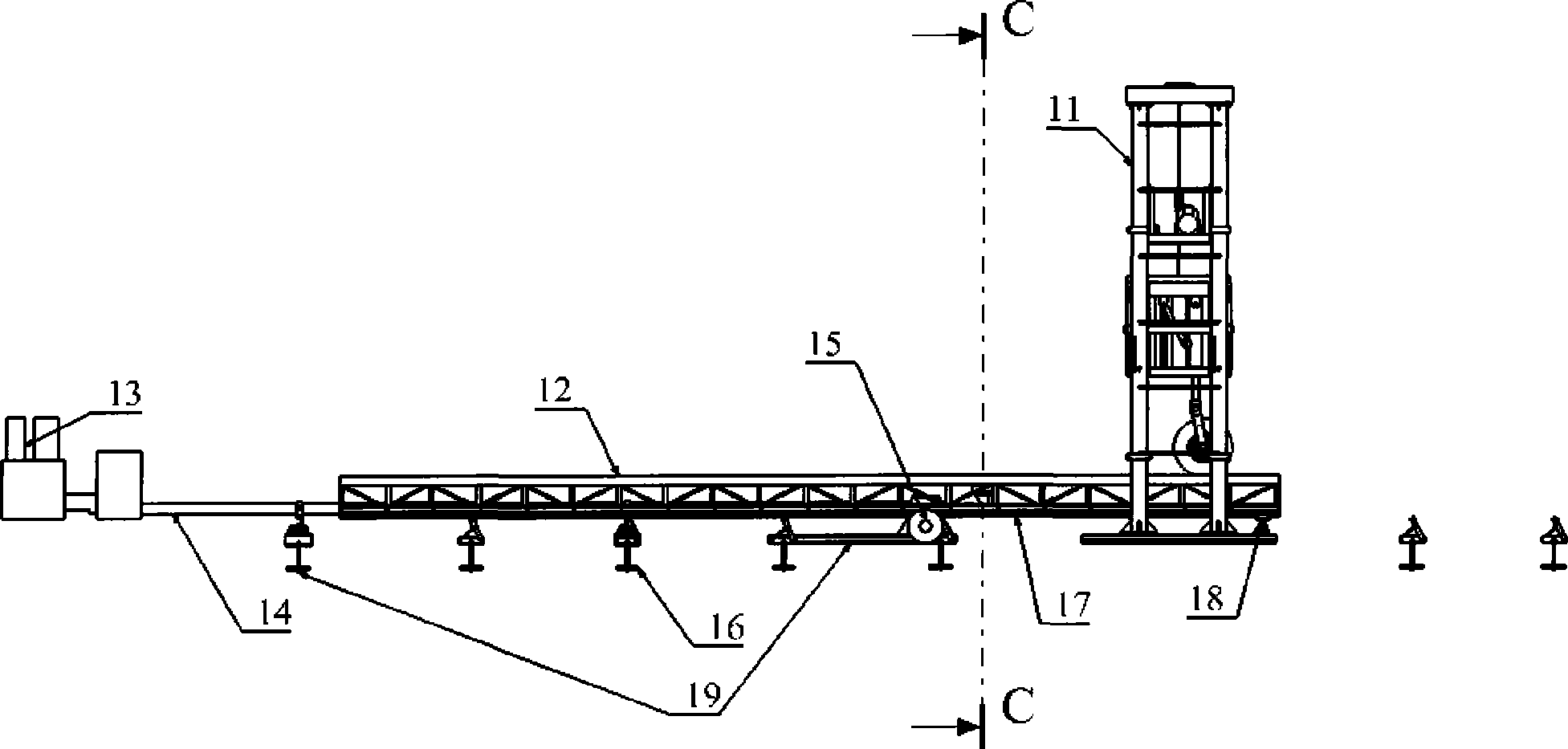

[0029] The aforementioned gantry 1 is a frame-type steel frame mechanism, which is composed of a column 11, a base plate 29, a side ladder 30 and a top beam frame 28, as image 3 , 4 shown. The column 11 is connected with the base plate 29 and the top beam frame 28 by bolts, the two columns on one side and the side ladder 30 are welded, and the gantry 1 is fixed on the ground through the ground fixing mechanism 5 .

[0030] The aforementioned movable impact platform 2 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com